High sealing ball valve

A technology of high sealing and ball valves, applied in the direction of shaft sealing, valve details, valve devices, etc., can solve the problems of increased friction, no sealing compensation, poor sealing effect, etc., to achieve improved sealing effect, reliable sealing performance, and improved sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

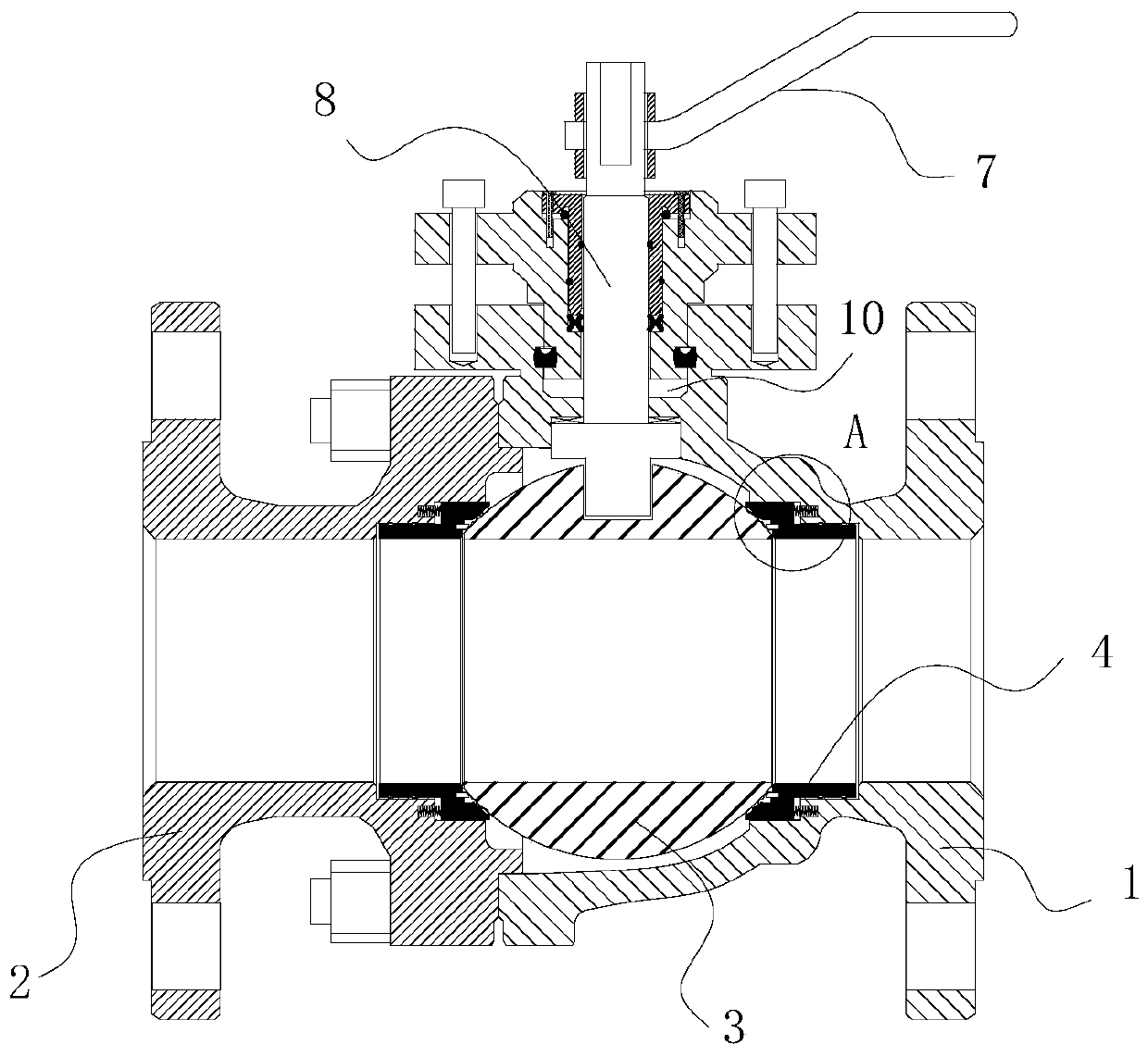

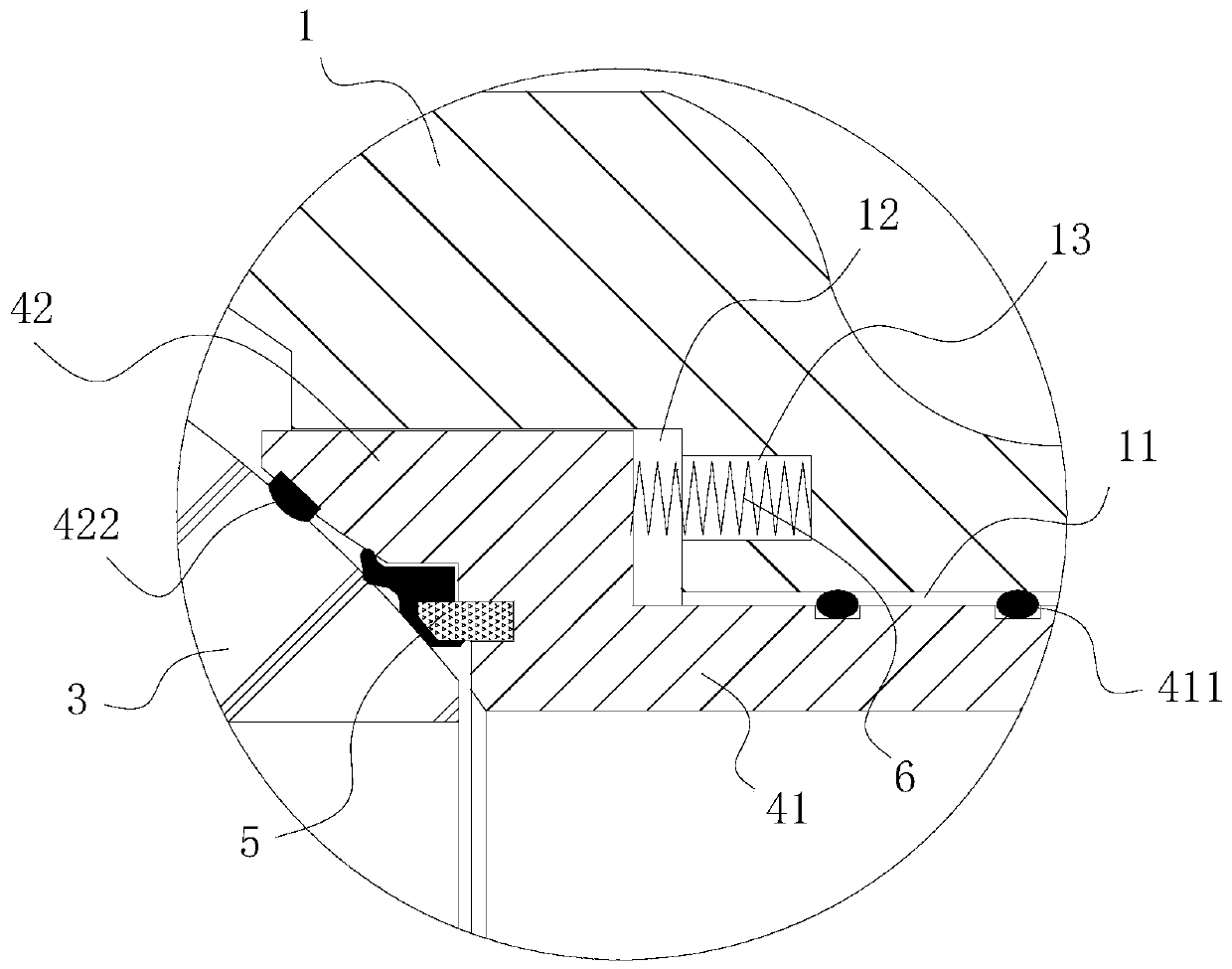

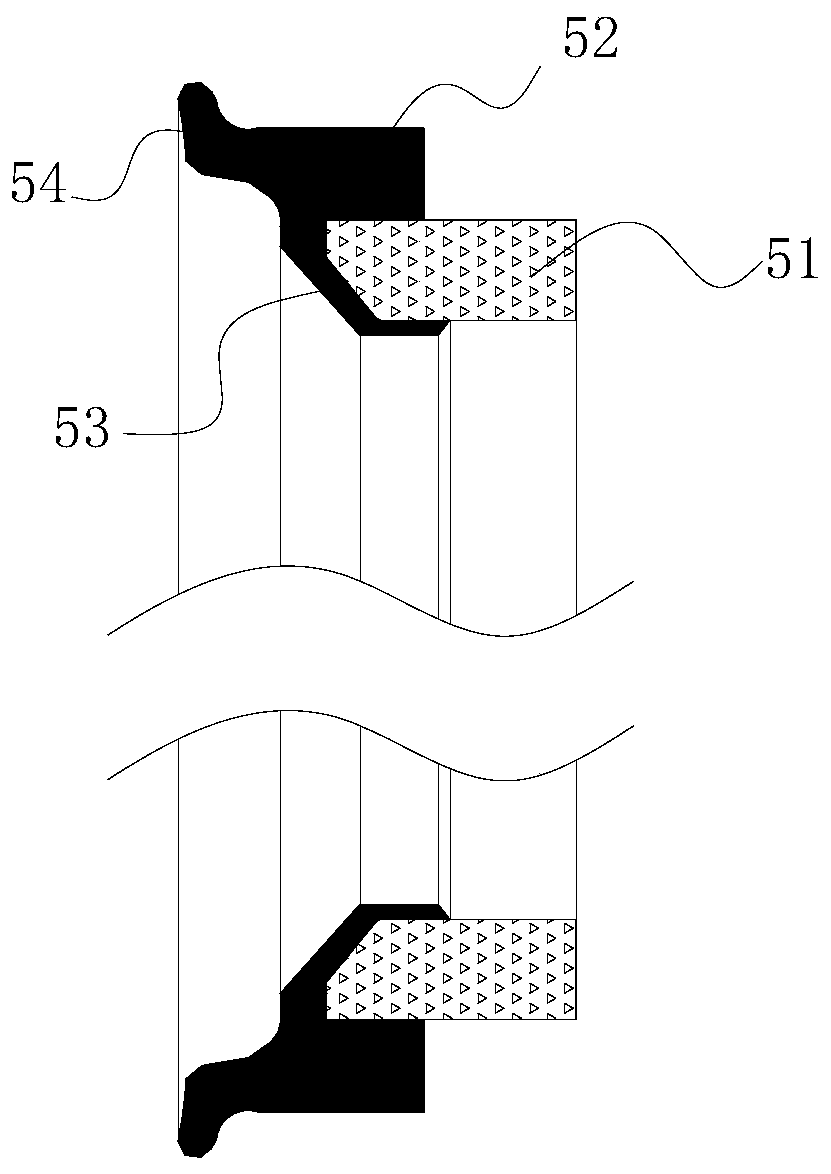

[0018] refer to Figure 1 to Figure 7 A high sealing performance ball valve of the present invention comprises an inlet valve body 1, an outlet valve body 2, a ball valve 3, a valve seat 4, a first sealing member 5, a spring 6, a handle 7 and a valve stem control mechanism 8, the inlet valve body 1 and the outlet valve body 2 form a cavity for accommodating the ball valve 3. The inlet valve body 1 and the outlet valve body 2 are installed with two symmetrically arranged valve seats 4, and the ball valve 3 is installed on two In the valve seat 4, several springs 6 are respectively installed in the inlet valve body 1 and the outlet valve body 2, and a first sealing member 5 is installed on the end of the valve seat 4 close to the ball valve 3, and the first sealing member 5 It abuts against the ball valve 3, and the other end of the valve seat 4 abuts against the spring 6. The upper part of the inlet valve body 1 is provided with a connection cavity 10 for installing the valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com