A rainwater diversion device for metal roof and metal roof

A shunt device and metal roofing technology, applied in the direction of roofing, roof drainage, roof covering, etc., can solve the problems of hidden water leakage, corrosion of lining board, hidden water leakage and other problems, achieve beautiful outer surface, avoid easy rust, and improve service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

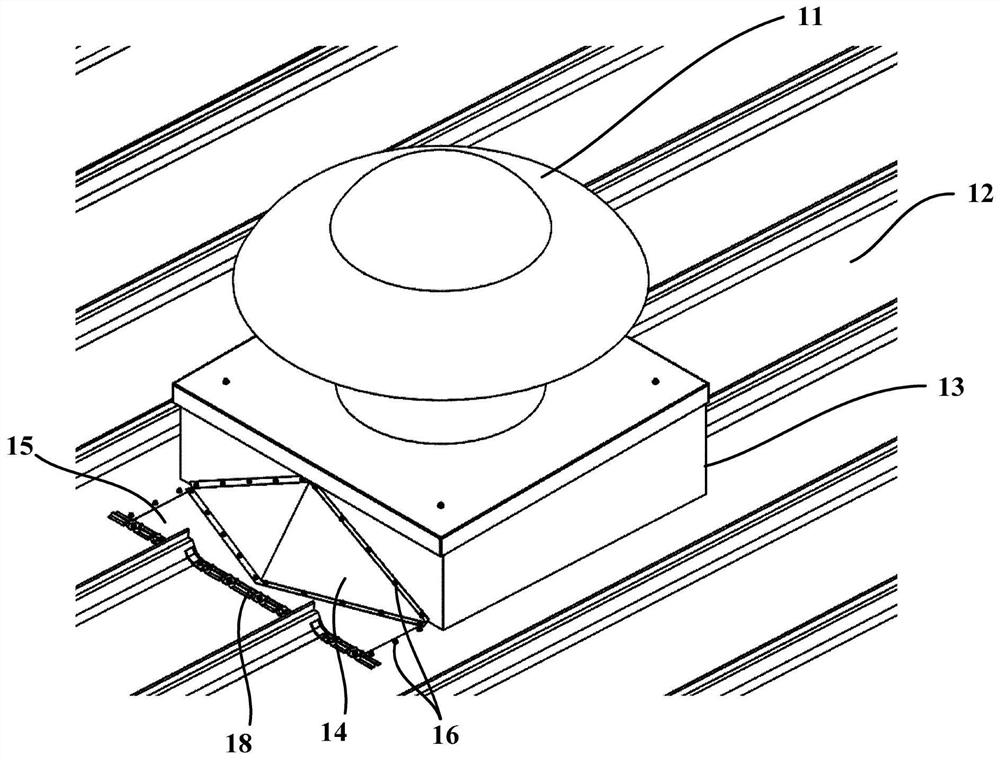

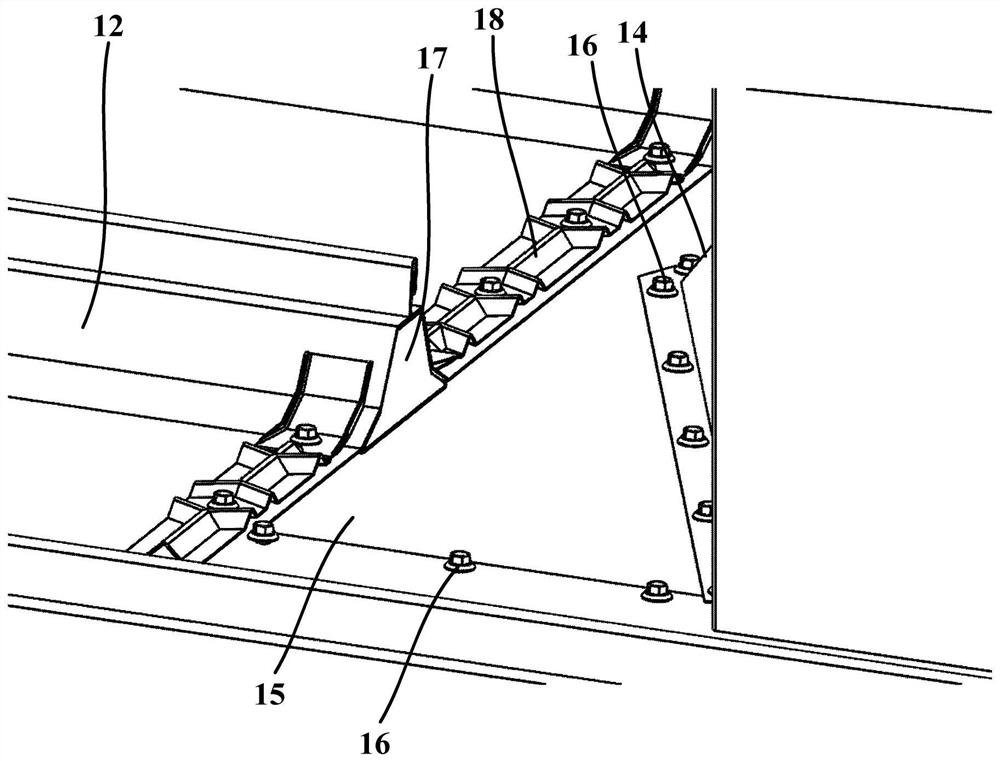

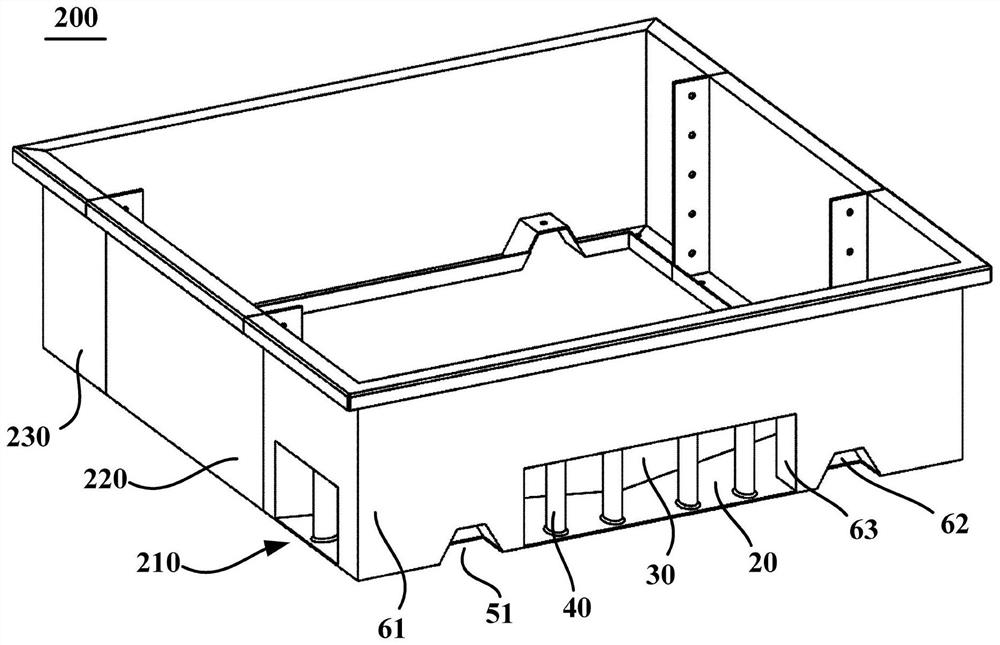

[0037] image 3 It is a schematic structural diagram of the rainwater diversion device provided by the present invention. Such as image 3 shown, and refer to Figure 4 to Figure 8 , the embodiment of the present invention provides a rainwater diversion device 200 for a metal roof, and the rainwater diversion device 200 may have a front-end drainage part 210 . The front-end drainage part 210 includes a distribution bottom plate 20 , a drainage plate 30 , a plurality of hollow columns 40 and a plurality of first connection structures.

[0038] The distribution bottom plate 20 is disposed on the upper side of the roof panel 100 of the metal roof. The diversion plate 30 extends upwards from the distribution bottom plate 20 , so that the water flowing from the front side of the distribution bottom plate 20 flows to one side or both sides of the distribution bottom plate 20 . The diversion plate 30 can be integrally formed with the distribution bottom plate 20 , for example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com