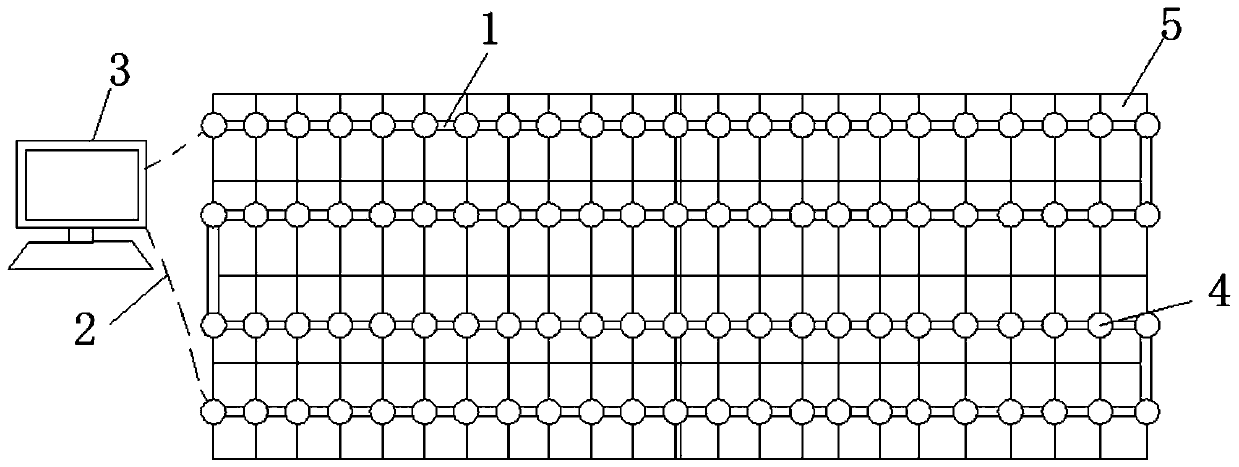

Metal roof plate reinforcing device with monitoring function

A reinforcement device and metal house technology, which is applied to measuring devices, roofs using flat/curved panels, roofs, etc., can solve the problems of wind exposure time and specific location difficult to locate, initial phenomenon is not obvious, large area, etc., to achieve suppression Scattering debris from wind exposure, improved wind resistance performance, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

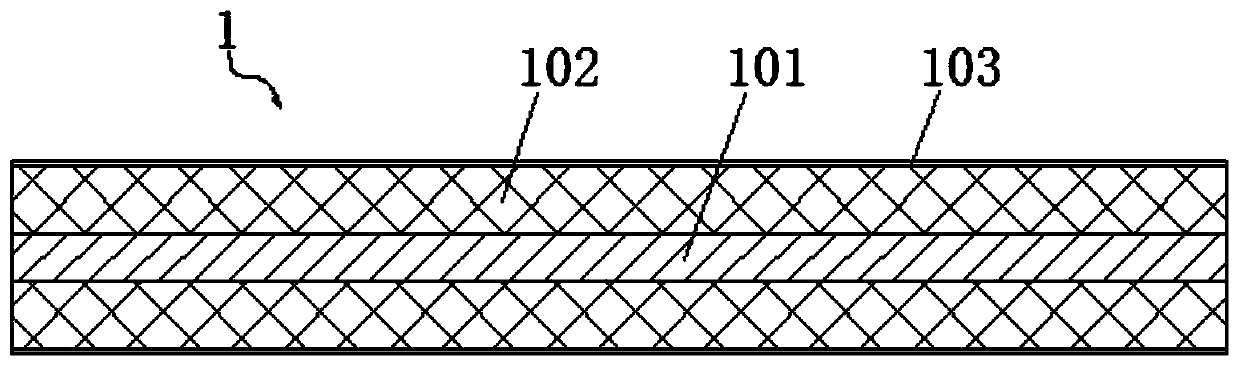

[0023] As an embodiment of the present invention, the sensing element 101 is a fiber Brillouin or fiber grating sensing element.

[0024] As an embodiment of the present invention, the surface of the reinforced fiber composite bar 102 is coated with an anti-ultraviolet coating 103 .

[0025] As an embodiment of the present invention, the transmission line 2 adopts an armored optical cable.

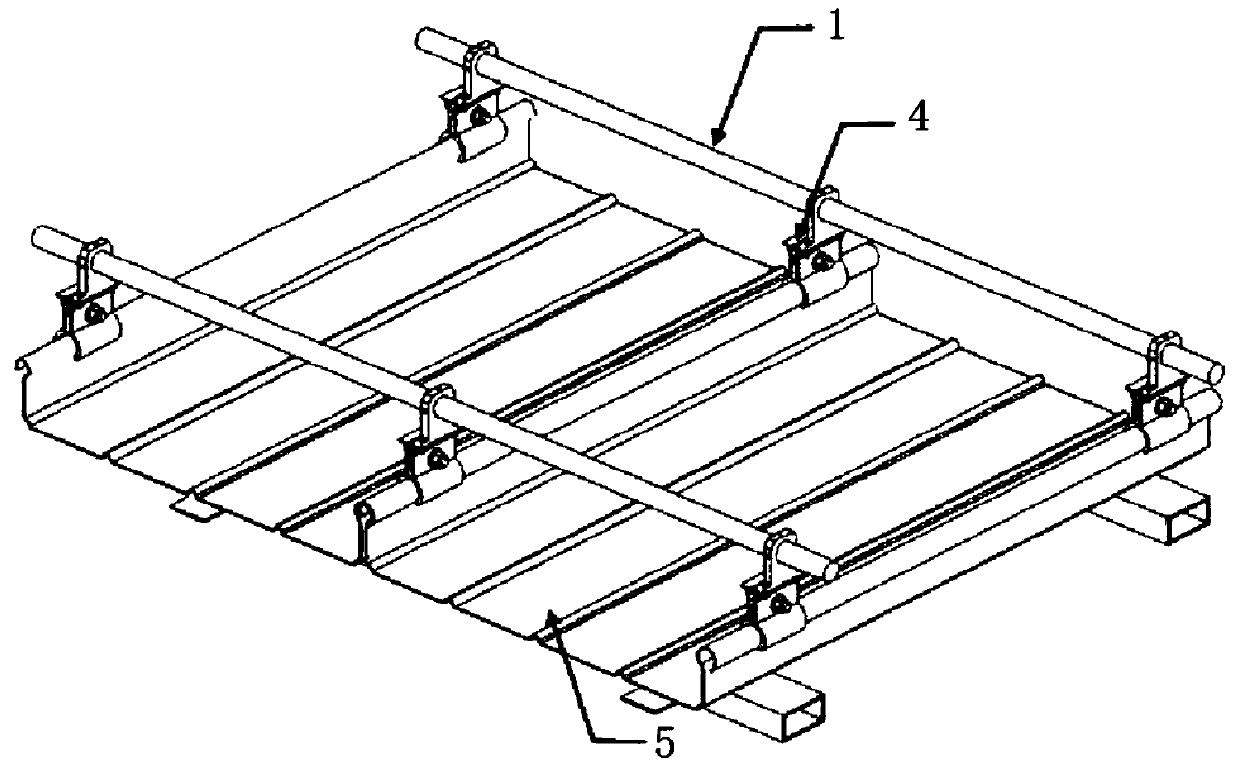

[0026] As an embodiment of the present invention, the reinforcing rib fixing support 4 includes a reinforcing rib positioning block 401, a fixed splint 402, a movable splint 403 and a locking bolt 404. The through hole 405 through which the reinforcing rib 1 passes, the lower side of the reinforcing rib positioning block 401 is fixedly equipped with a fixed splint 402, and the side of the fixed splint 402 is equipped with a movable splint 403, and it is useful to install between the movable splint 403 and the fixed splint 402. Locking bolt 404 for adjusting clamping force.

[0027] In a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com