Numerical control machine tool cutter wear loss online prediction method based on spindle currents and vibration signals

A technology of tool wear and CNC machine tools, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of low prediction model accuracy and poor model generalization, and achieve improved generalization, good generalization, Effect of High Prediction Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

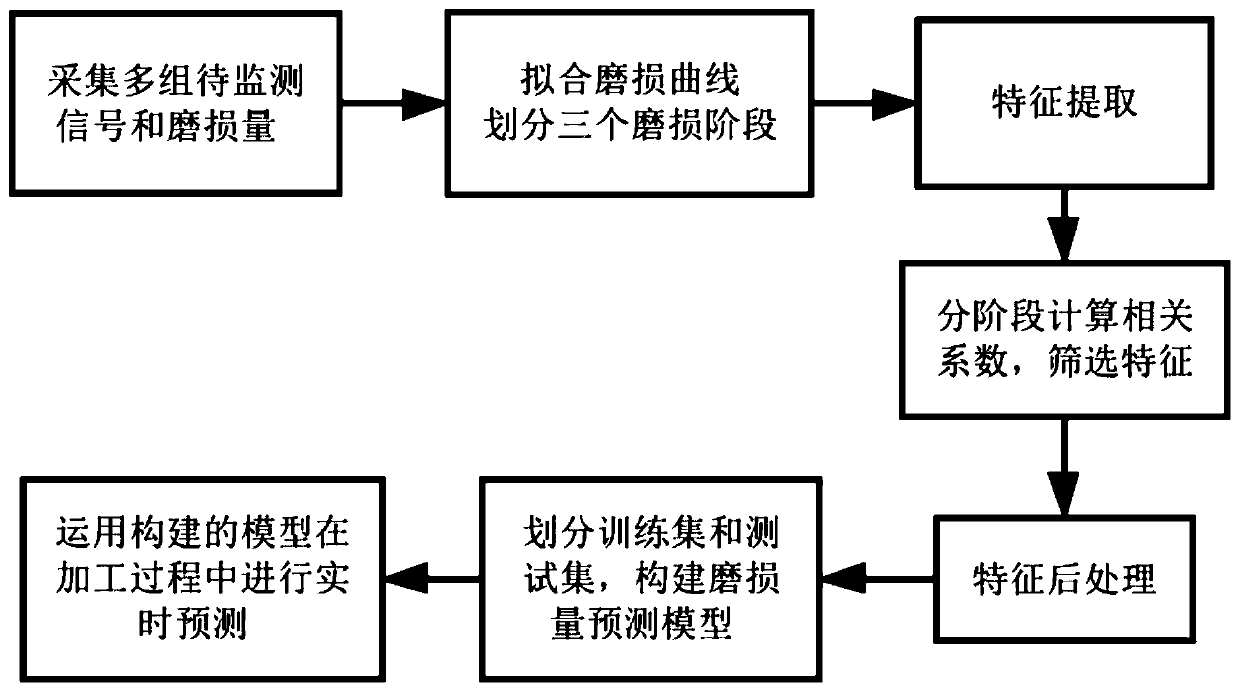

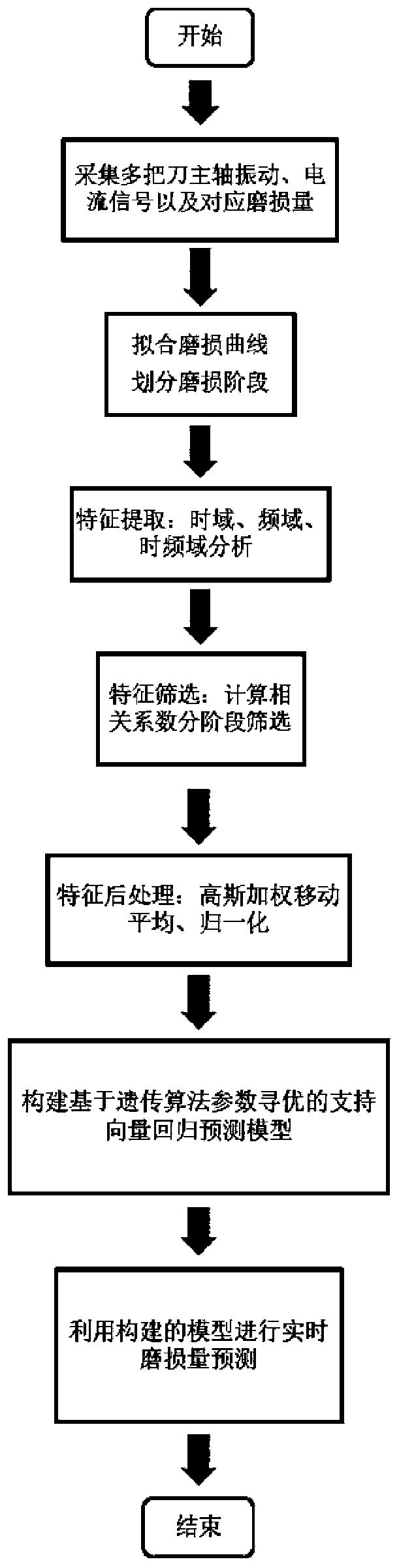

[0021] Such as figure 1 with figure 2 As shown, this embodiment relates to a specific process of a tool wear prediction method, including the following steps:

[0022] Step 1. Set the cutting parameters as follows: spindle speed 2000RPM, feed rate 300mm / min, depth of cut 1mm, width 4.5mm, under this parameter setting, use three Sandvik 8mm diameter 3-blade flat end mills for 45 The steel workpiece is processed by face milling, and the length of each tool pass is 120mm. The Kistler three-axis acceleration sensor is used to collect the vibration signal of the spindle, and the current sensor is used to collect the single-phase current signal of the spindle.

[0023] The sampling frequency of the vibration signal is 20kHz, and the sampling frequency of the current signal is 5kHz.

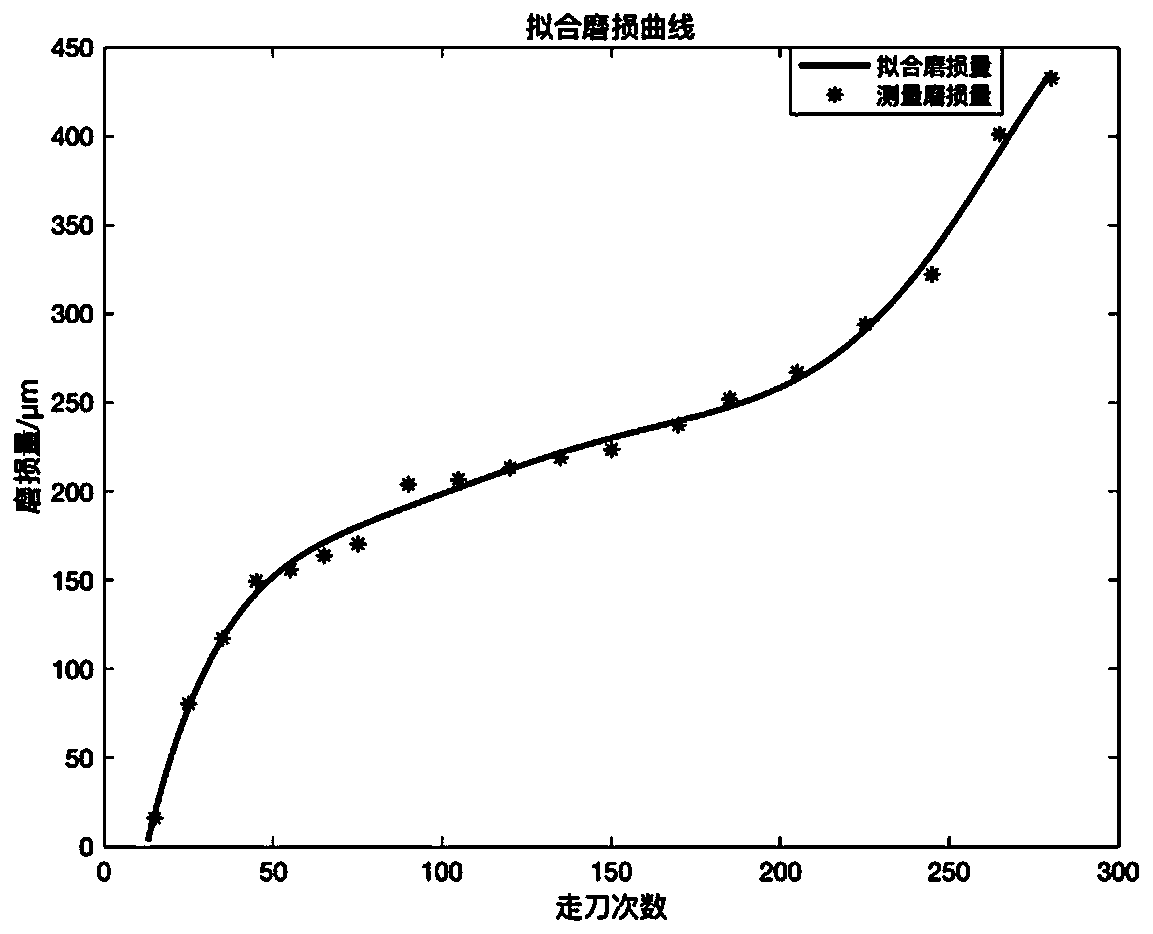

[0024] Preferably, after a certain period of processing, stop the machine and unload the cutter once, use a microscope to measure the amount of wear on the flank of the cutter and record the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com