Drilling and copper deposition all-in-one equipment for processing via holes of circuit boards

A technology of circuit boards and via holes, which is applied in the field of integrated equipment for drilling and sinking copper, and can solve problems such as the purchase cost of muscle-enhancing equipment and the reduction in production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

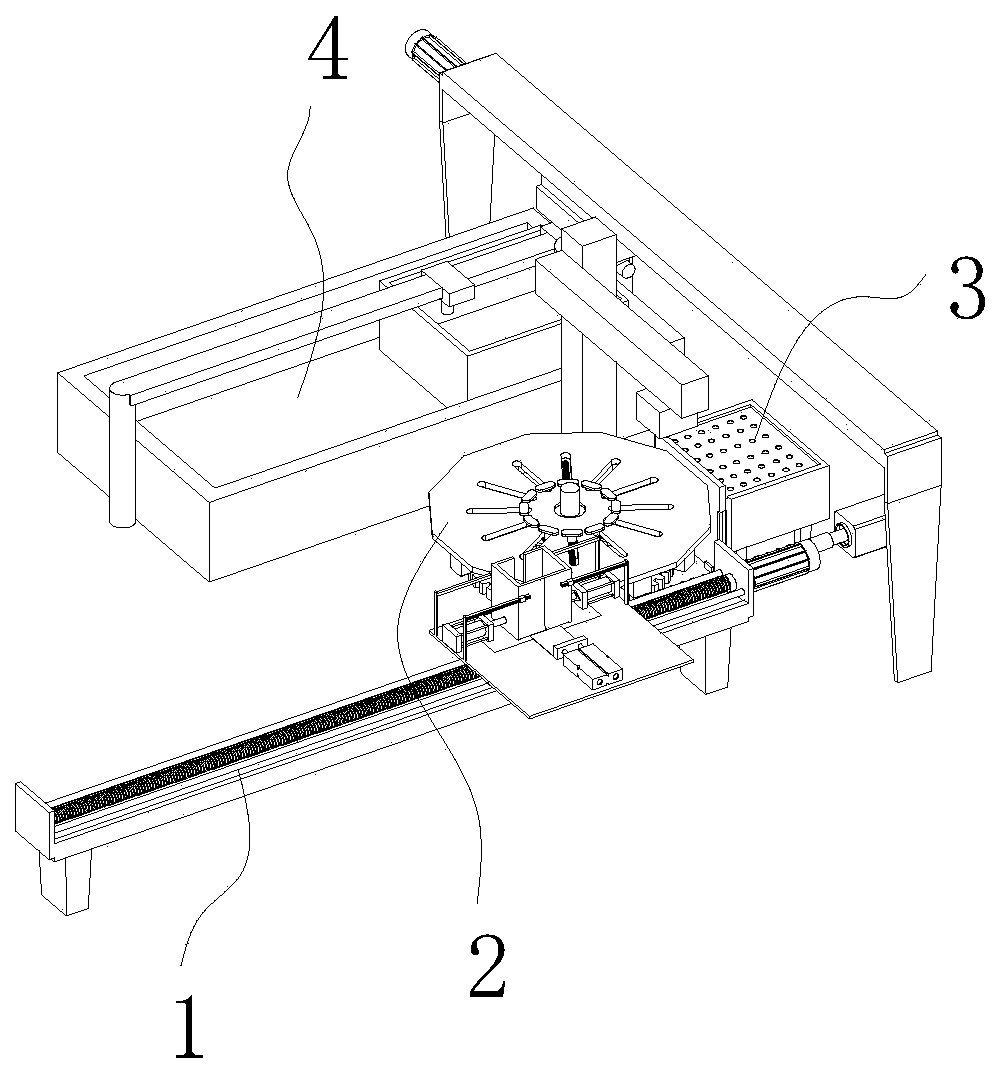

[0038] As an embodiment of the present invention, the present invention proposes an integrated equipment for drilling and sinking copper for circuit board via hole processing, including a loading and unloading mechanism, a drilling mechanism, a transfer mechanism and a copper sinking mechanism, and a loading and unloading mechanism The output end of the drilling mechanism is connected to the input end of the drilling mechanism, the output end of the drilling mechanism is connected to the input end of the transfer mechanism, and the output end of the transfer mechanism is connected to the input end of the sinking copper mechanism, wherein:

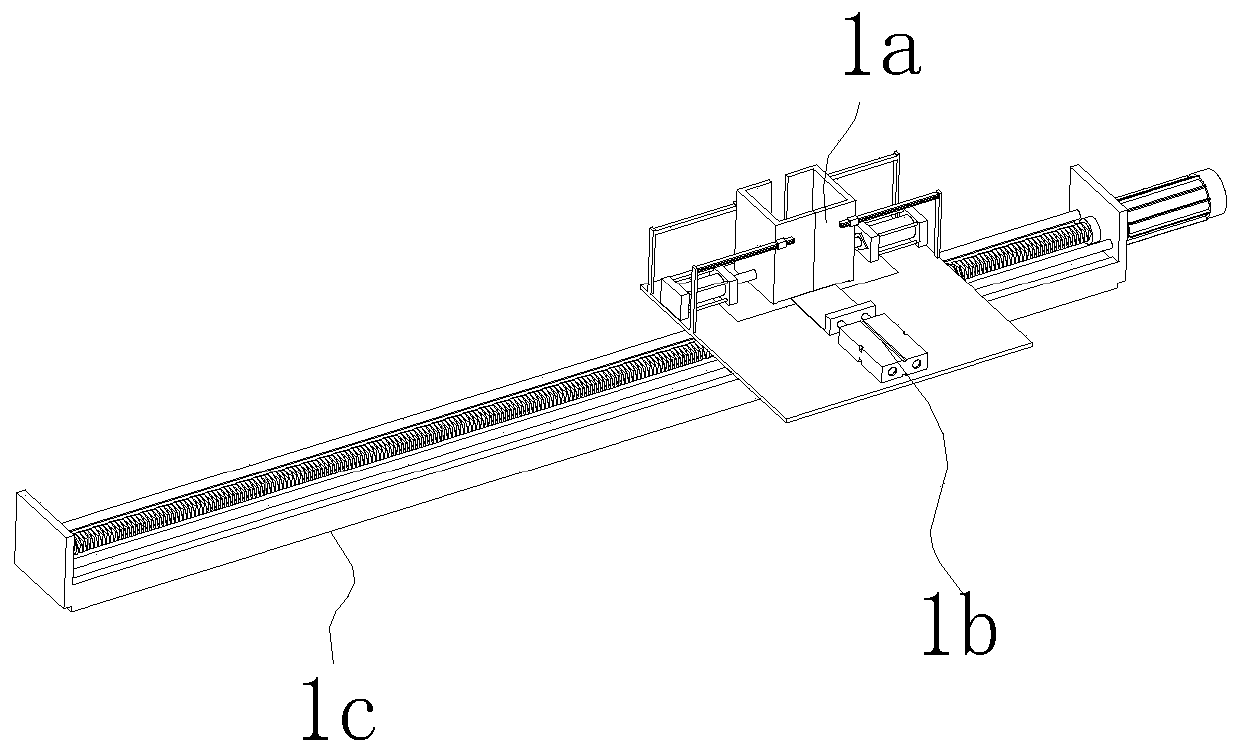

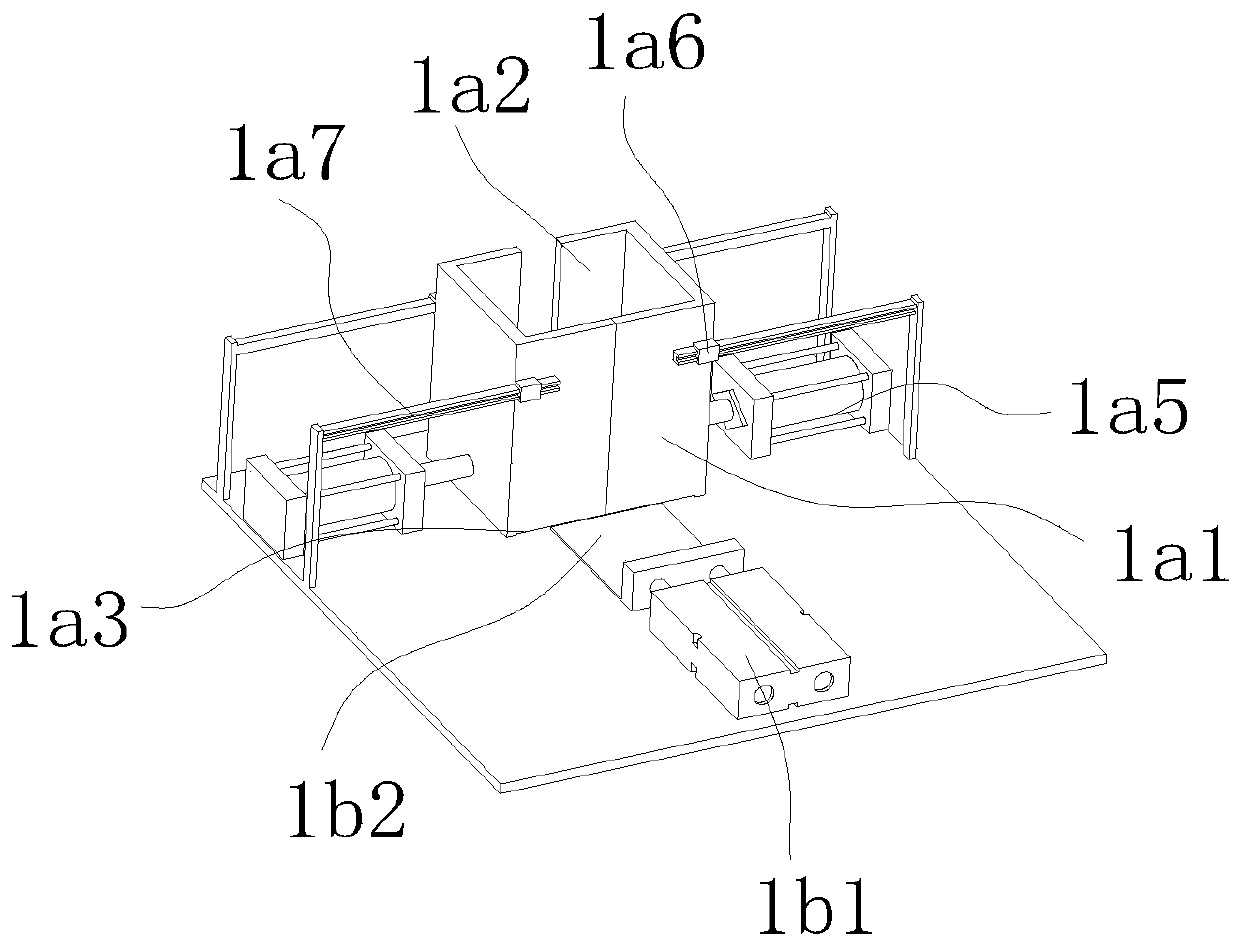

[0039] The loading and unloading mechanism includes a storage assembly and a feeding assembly. The side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com