Burr-free stamping die

A technology of burr-free stamping and stamping dies, which is applied in the direction of manufacturing tools, safety equipment, grinding machines, etc., can solve the problems of stamping support block damage, inability to remove burrs, and affect the use of parts, and achieve the effect of reducing grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

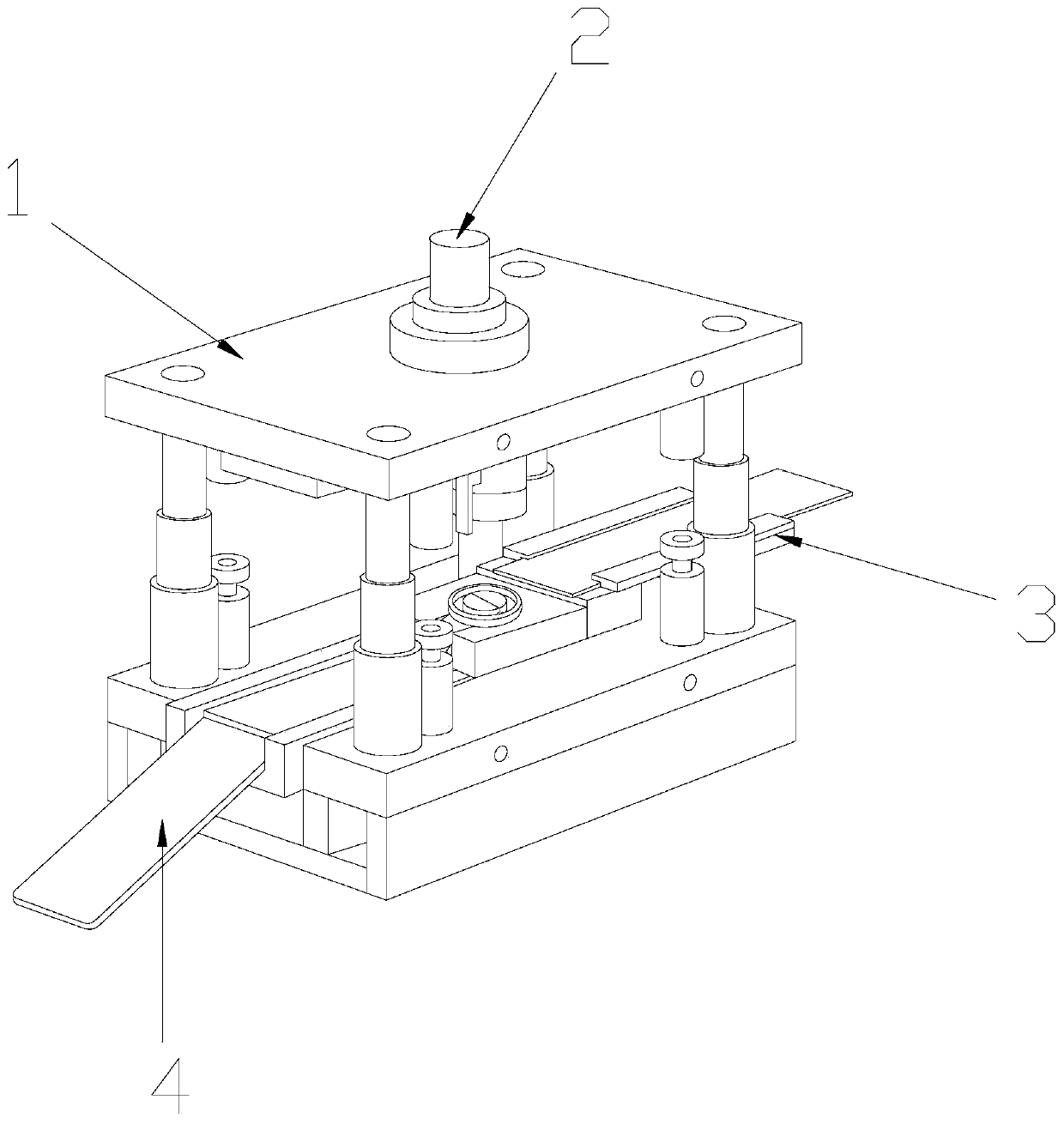

[0031] see Figure 1-Figure 5 , the present invention provides a burr-free stamping die, the structure of which includes a stamping die 1, a power pressing rod 2, a feeding device 3, and a discharge plate 4, and a power pressing rod 2 is provided at the middle position of the top of the stamping die 1, so that The stamping die 1 is mechanically connected with the power pressure rod 2, the feeding device 3 is installed on the bottom end of the inner side of the stamping die 1, and the left end of the stamping die 1 is provided with a discharge plate 4, and the stamping die 1 It is movably connected with the unloading plate 4;

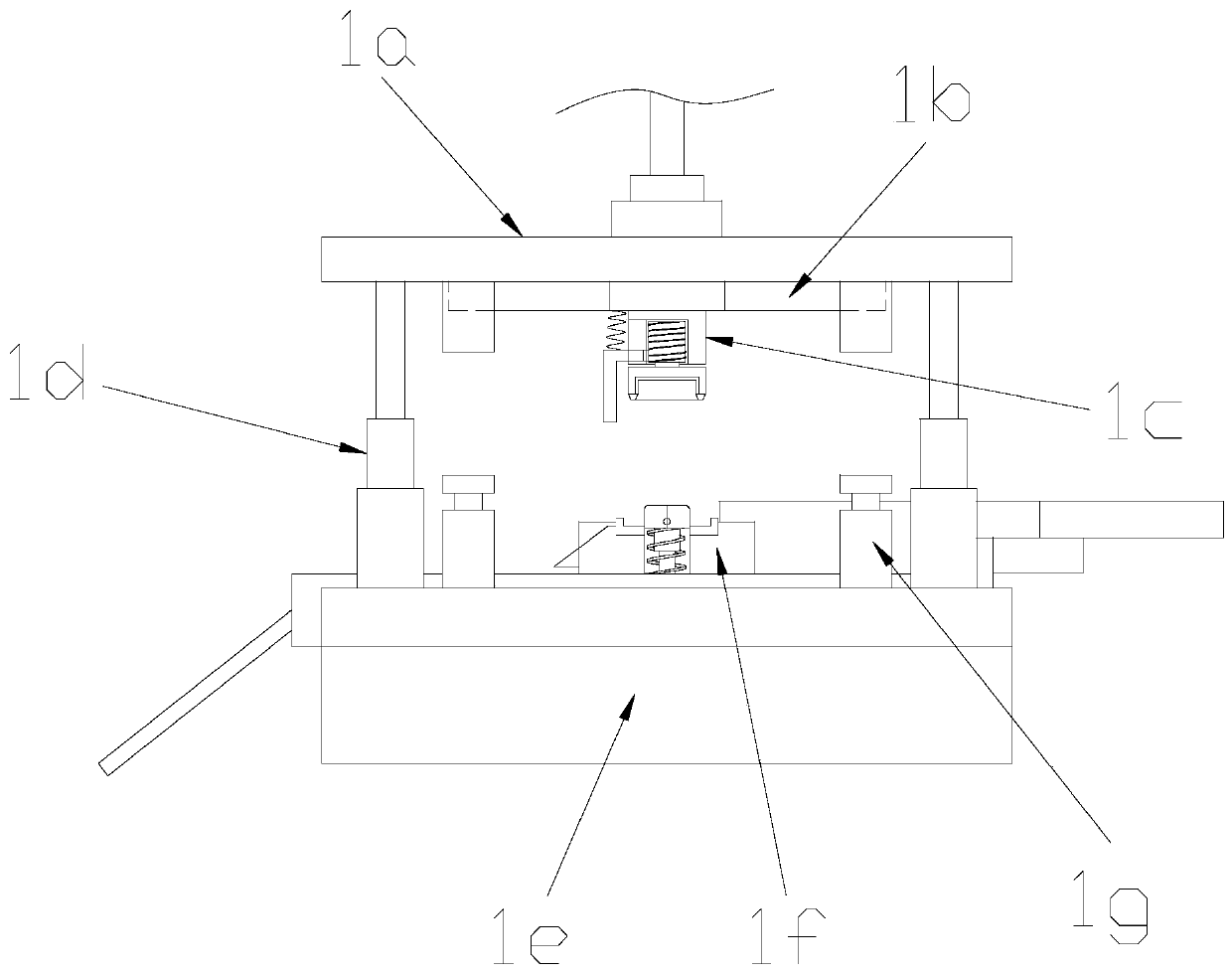

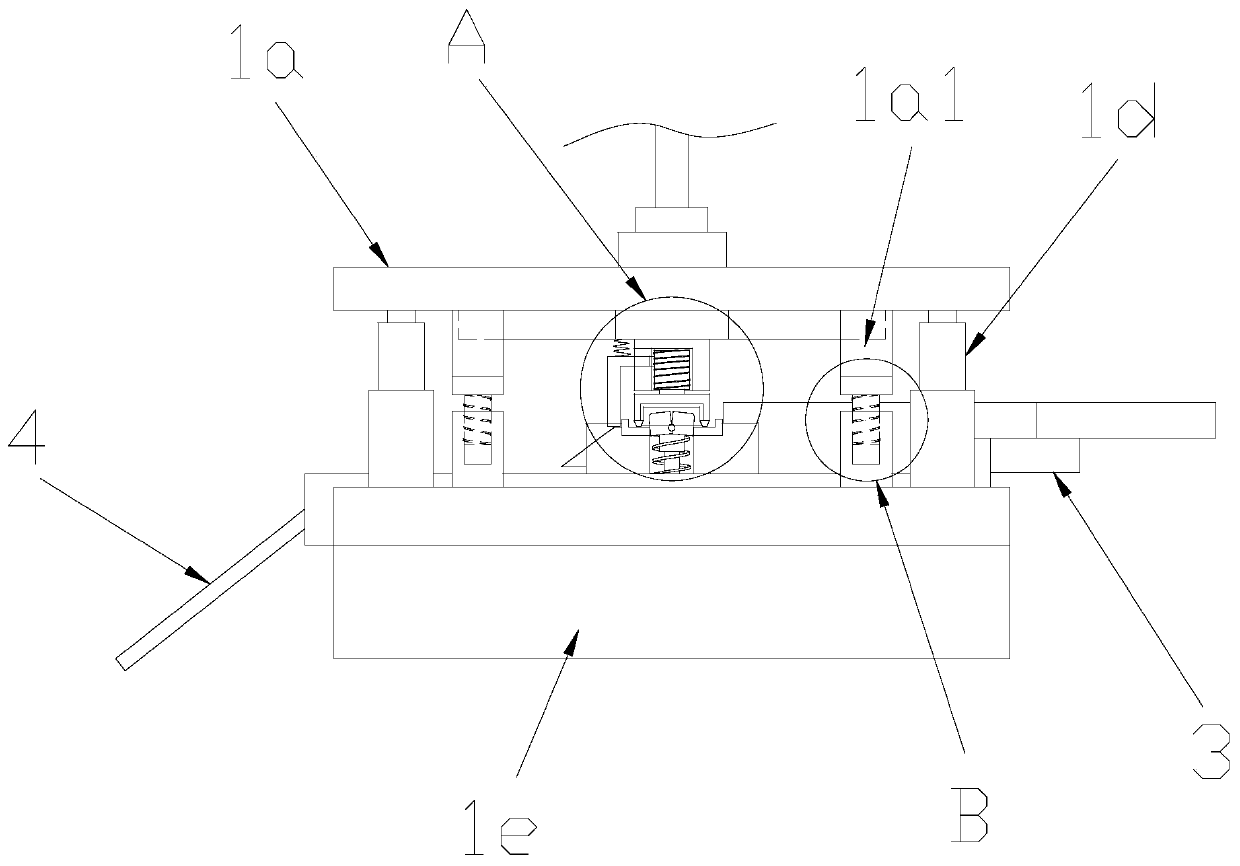

[0032] The stamping die 1 is composed of an upper die base 1a, an upper backing plate 1b, a stamping mechanism 1c, a guide post sleeve rod 1d, a lower die base 1e, a discharge mechanism 1f, and a buffer support mechanism 1g. The upper die base 1a The bottom end is provided with an upper backing plate 1b, the upper die base 1a is connected with the upper...

Embodiment 2

[0043] see Figure 1-Figure 6 , the present invention provides a burr-free stamping die, the buffer support mechanism 1g is composed of a limit cylinder base 1g1, a thread groove 1g2, a buffer thread rod 1g3, and a buffer gasket 1c4, and the inside of the limit cylinder base 1g1 is There is a thread groove 1g2, the thread groove 1g2 is provided with a buffer thread rod 1g3, the thread groove 1g2 and the buffer thread rod 1g3 are threadedly connected, and the top of the buffer thread rod 1g3 is provided with a buffer gasket 1c4, so The above-mentioned buffer threaded rod 1g3 is glued to the buffer gasket 1c4.

[0044] The upper mold base 1a and the lower mold base 1e are parallel to each other, and the length and width are the same. The top clamping rod 1f21 and the stamping support block 1f5 are fitted together through the tapered extrusion groove 1f51. The buffer gasket 1c4 is made of rubber material, which is not suitable for damage and has strong flexibility. The feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com