Profile stretch bending device for aircraft manufacturing

A technology for aircraft manufacturing and profiles, which is applied in the field of profile drawing and bending devices for aircraft manufacturing, can solve problems such as damage to the device mechanism, damage to the profile by the clamping mechanism, instability, etc., so as to improve the life of the device, improve the detection effect, and avoid damage. The effect of profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

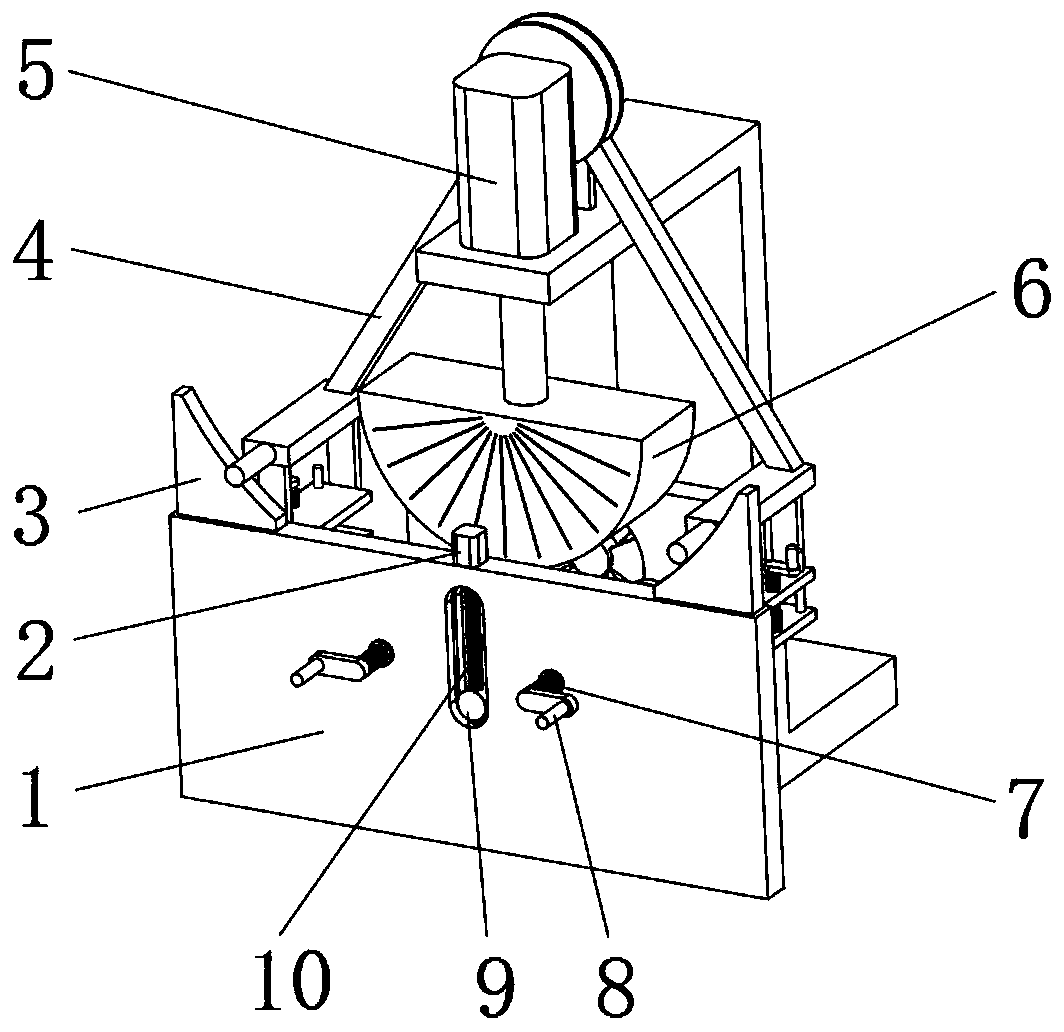

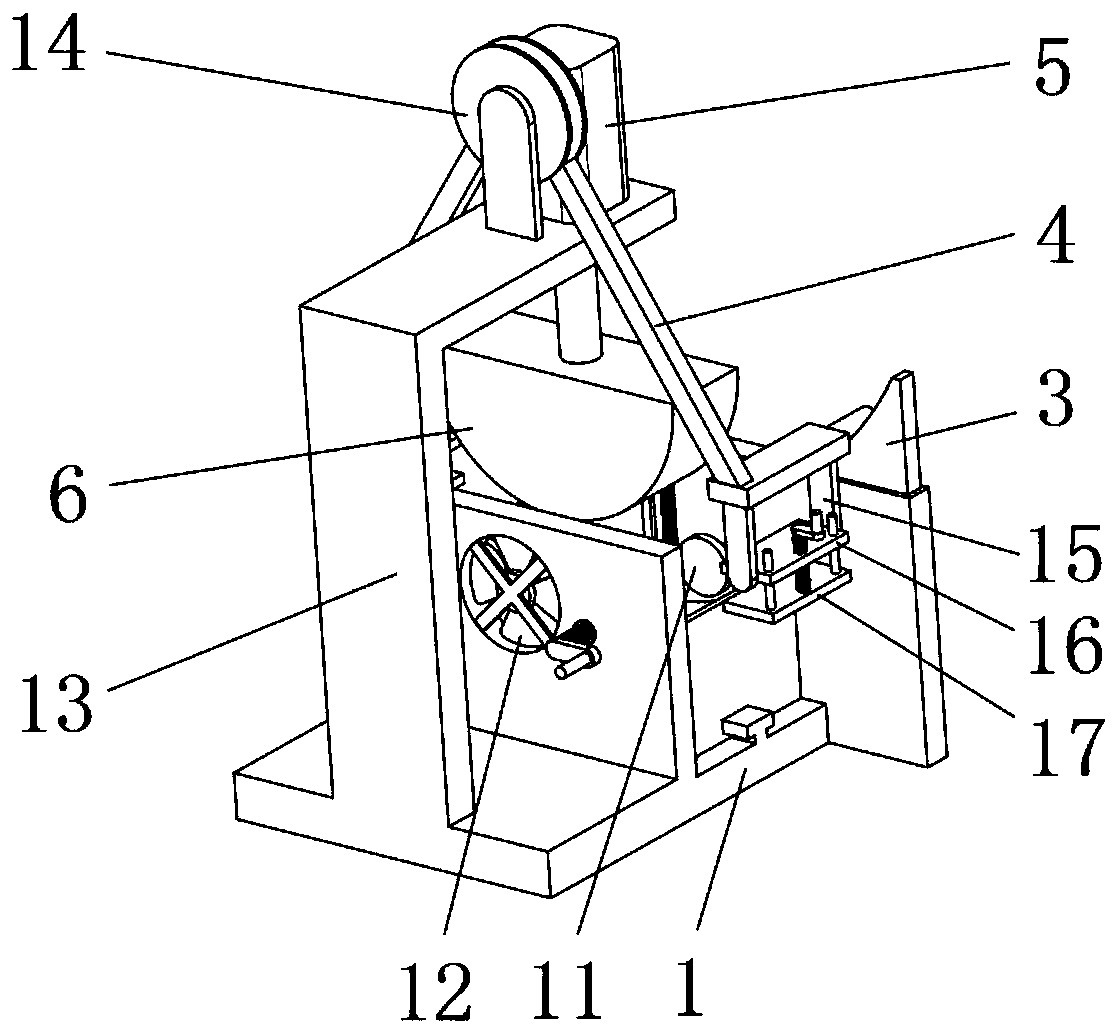

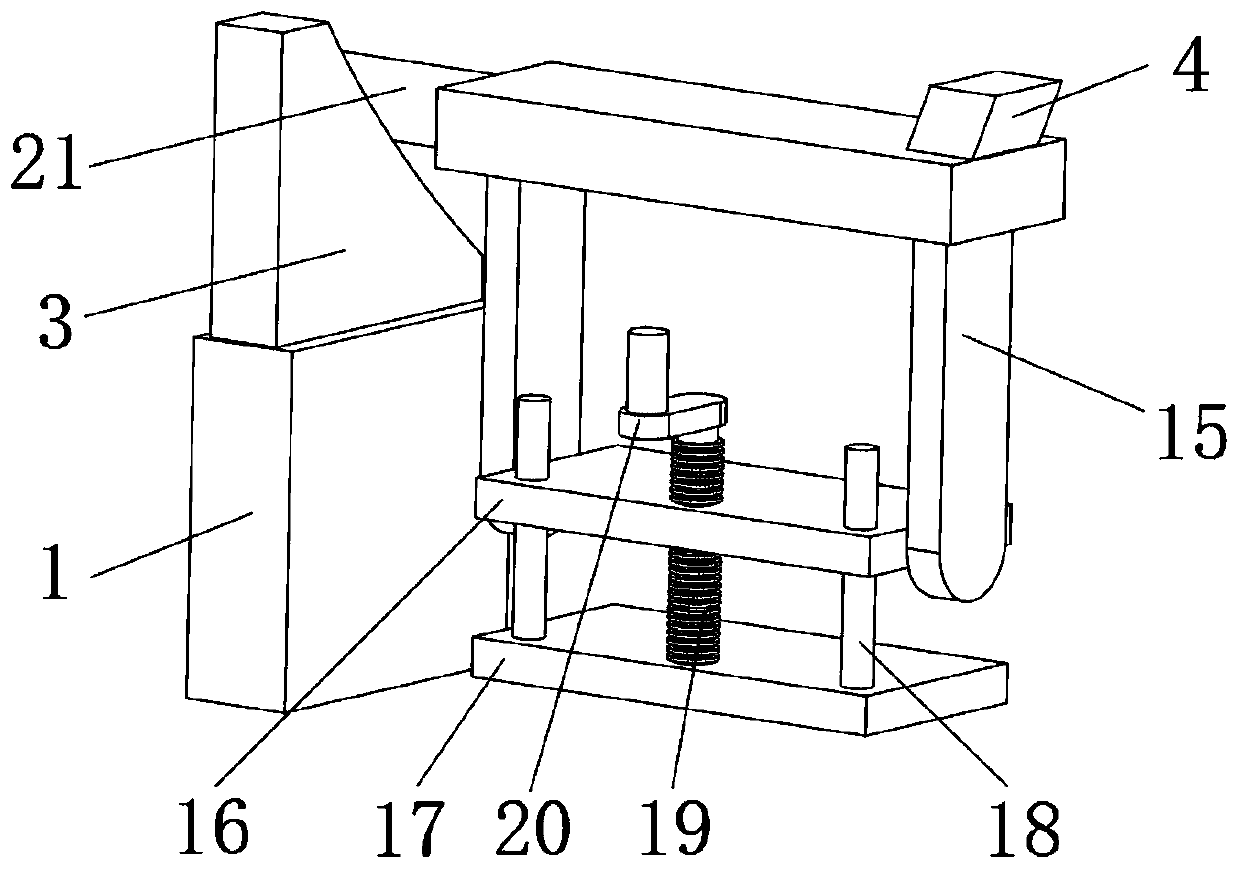

[0036] A profile stretch bending device for aircraft manufacturing, such as Figure 1-3 As shown, it includes a base 1, a pressing mechanism, a clamping mechanism and a detection mechanism; the outer wall of one side of the base 1 is welded with a mounting frame 13, and the pressing mechanism includes a hydraulic cylinder 5 and a bending head 6, and the hydraulic cylinder 5 is fixed to the top outer wall of the installation frame 13 by bolts, and the output end of the installation frame 13 is fixed to the top outer wall of the bending head 6 by bolts; the clamping mechanism includes two connecting arms 4, two connecting frames 15, two A first splint 16 and two second splints 17; the top outer wall of the mounting frame 13 is fixed with a turntable assembly 14 by bolts, and the connecting arm 4 has a symmetrical structure; and the inner wall at one end of the connecting arm 4 is slidably connected to the turntable through a support shaft The inner walls on both sides of the com...

Embodiment 2

[0047] A profile stretch bending device for aircraft manufacturing, such as Figure 6 As shown, in order to improve the processing effect; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of one side of the turntable assembly 14 is fixed with a second motor 27 through the second motor base, and the outer wall of the other side of the turntable assembly 14 The third motor base is fixed with a third motor 28, the output end of the second motor 27 is connected to the outer wall of one connecting arm 4 through a synchronous wheel, and the output end of the third motor 28 is connected to the outer wall of another connecting arm 4 through a synchronous wheel. ; By arranging the second motor 27 and the third motor 28, it is possible to cooperate with stretching during the pressing process and improve the processing effect.

[0048] When this embodiment is in use, when the pressing mechanism presses the profiles, the second motor 27 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com