Electronic waste recycling treatment device and treatment method

A technology of electronic waste and recycling, which is applied in grain processing, chemical instruments and methods, wet separation, etc., can solve the problems of reducing metal recovery efficiency, environmental hazards, and increasing waste disposal costs, and achieves improved drying efficiency and enhanced drying effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

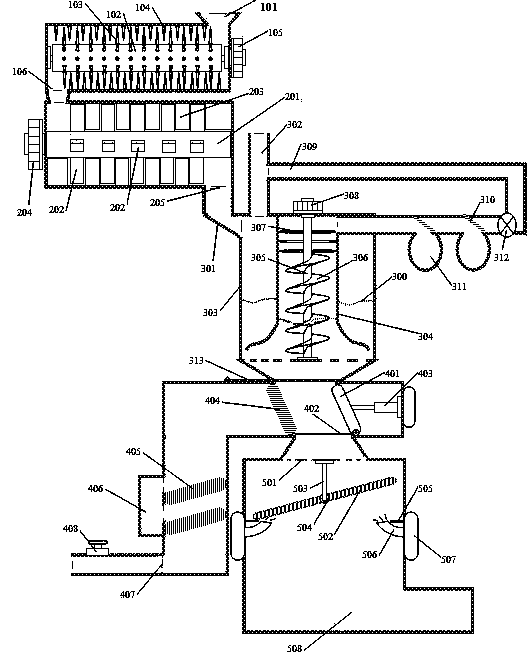

[0033] Further explanation in conjunction with accompanying drawings: Figure 1 to Figure 2 It is an e-waste recycling and processing device according to this embodiment, which includes a primary crushing chamber, a fine crushing chamber, a density separation device, a pressing water removal component and a drying chamber. in figure 1 It is an internal view, that is, the internal structure diagram after partial shell removal.

[0034] Such as figure 1 As shown, the primary crushing chamber includes a primary crushing chamber casing, an electronic waste inlet 101, a primary crushing shaft 102, a shaft crushing cone 103, a wall crushing cone 104, a primary crushing drive motor 105, and a primary crushing chamber discharge port 106; figure 1 The shell of the primary crushing chamber shown is a horizontal cylindrical structure with both ends closed, the entrance of the electronic waste is set on the top of the shell of the primary crushing chamber, and the primary crushing shaft...

Embodiment 2

[0046] A method for recycling and processing electronic waste, the processing method uses the electronic waste recycling and processing device of embodiment 1, specifically comprising the following steps:

[0047] (1) Put the electronic waste into the primary crushing chamber through the entrance of the electronic waste, start the primary crushing drive motor, the electronic waste is discharged into the fine crushing chamber through the inlet of the fine crushing chamber after primary crushing in the primary crushing chamber, and start The fine crushing drive motor finely crushes the electronic waste, and then discharges it through the discharge port of the fine crushing chamber. The maximum particle size of the crushed material discharged through the outlet of the fine crushing cavity is 18mm.

[0048] (2) The material crushed by the fine crushing cavity is discharged into the separation outer cavity through the inlet of the separation outer cavity and is the outside of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com