Glue spray pipe and glue spray equipment

A technology of spraying glue hose and glue hose, which is applied in the direction of coating, device for coating liquid on the surface, etc., which can solve the problems of inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

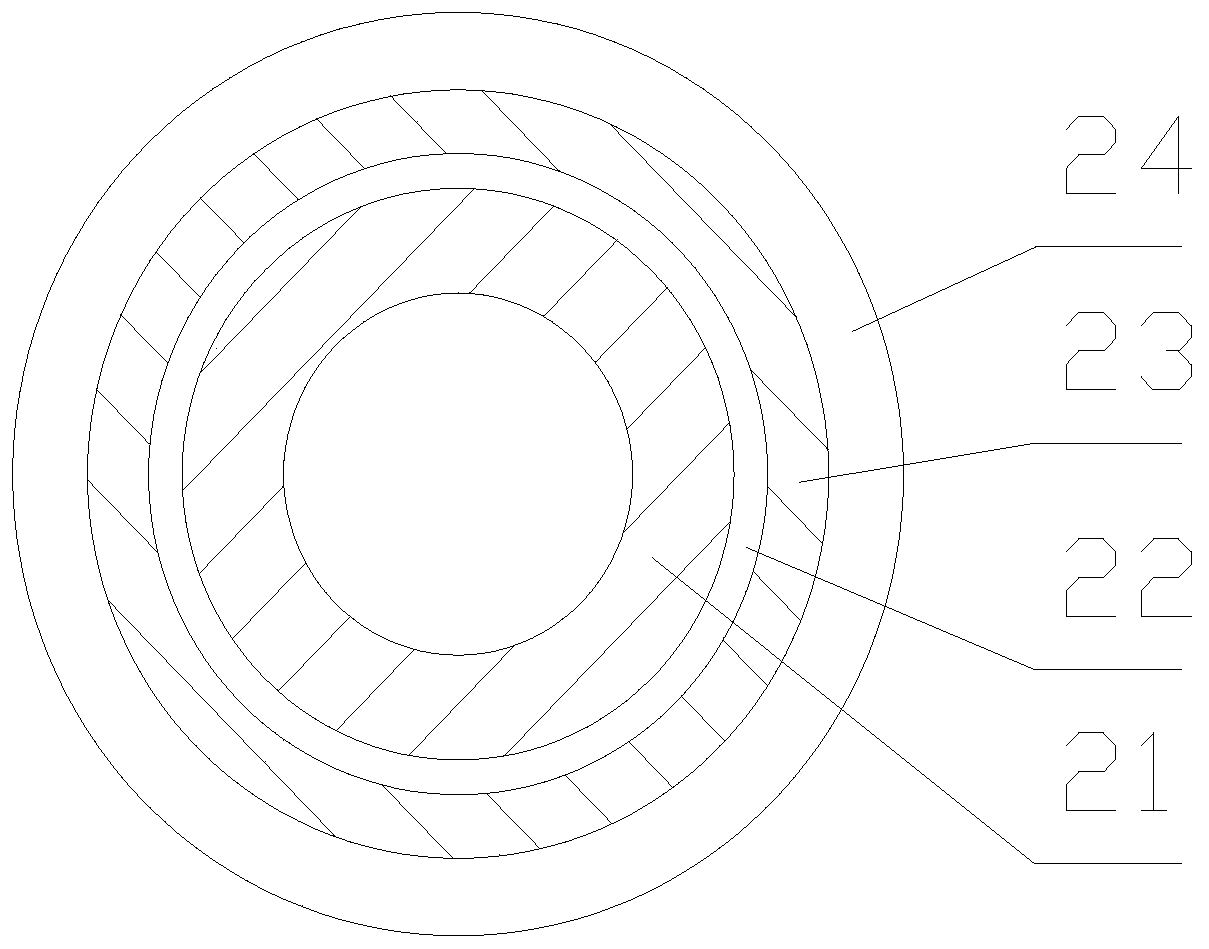

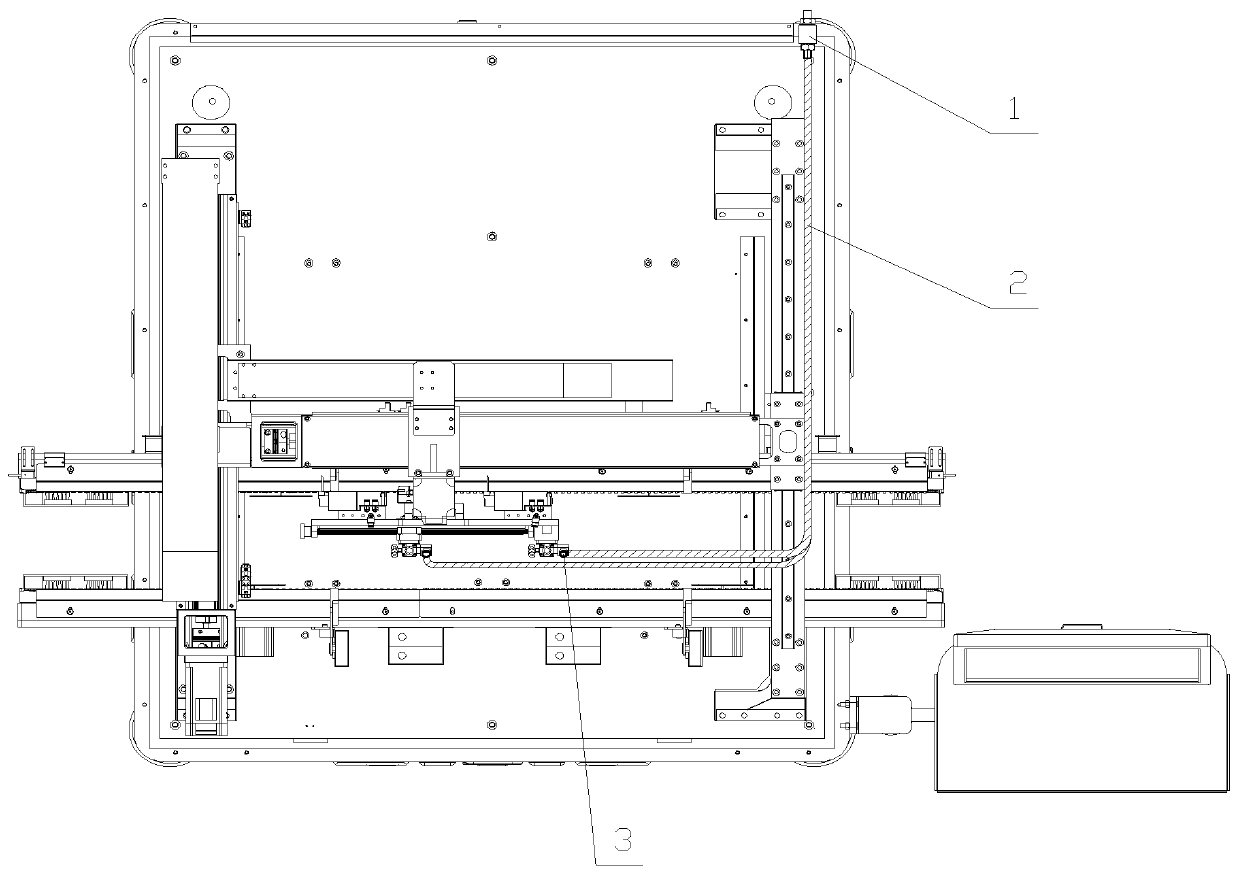

[0021] see in conjunction figure 1 As shown, according to the embodiment of the present application, a glue spraying hose 2 includes: a glue hose body, which is used to transport glue in the pipe; a heating layer 23, which is coated on the glue hose body, and is used to heat the glue hose body and The glue inside it; the temperature controller monitors the temperature of the glue and regulates the heating state of the heating layer 23 at the same time.

[0022] The hose 21 as the hose body for conveying glue is covered with a heating layer 23. When the heating layer 23 provides heat, the heat will be transferred to the glue inside along the hose 21, thereby preventing the glue from solidifying at low temperature. Can not flow or flow poorly; and for the working state of the heating layer 23, the glue temperature is monitored by the temperature controller to control, such as when the temperature of the glue is lower than the temperature that can be smoothly circulated, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com