Resin molded product unit and molding method of resin molded product unit

A technology of resin molding and molding method, which is applied in the field of resin molding unit and resin molding unit molding, and can solve problems such as side edge insertion of difficult sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

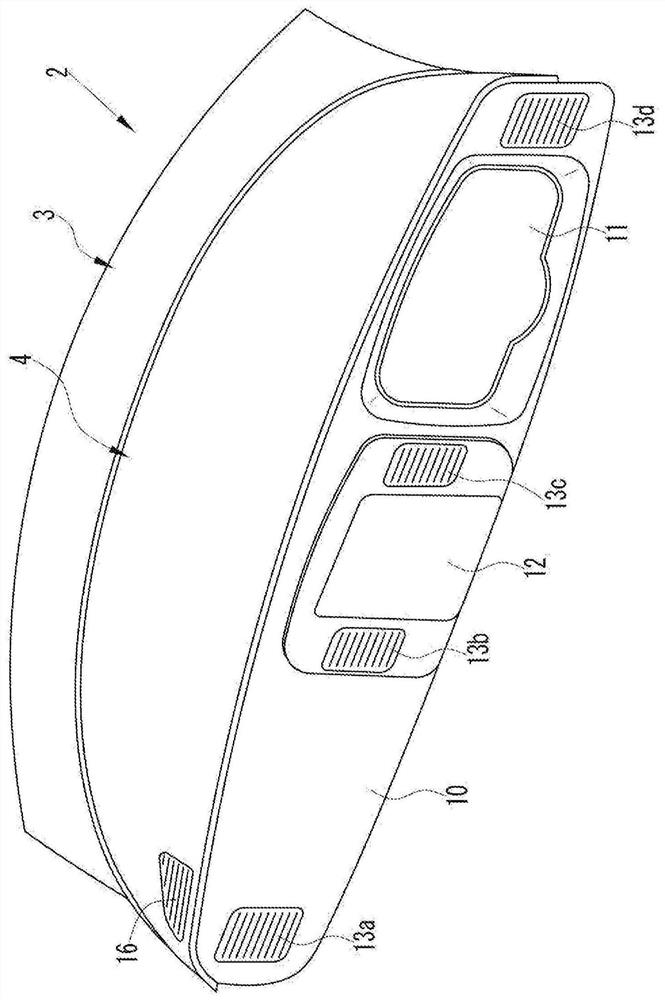

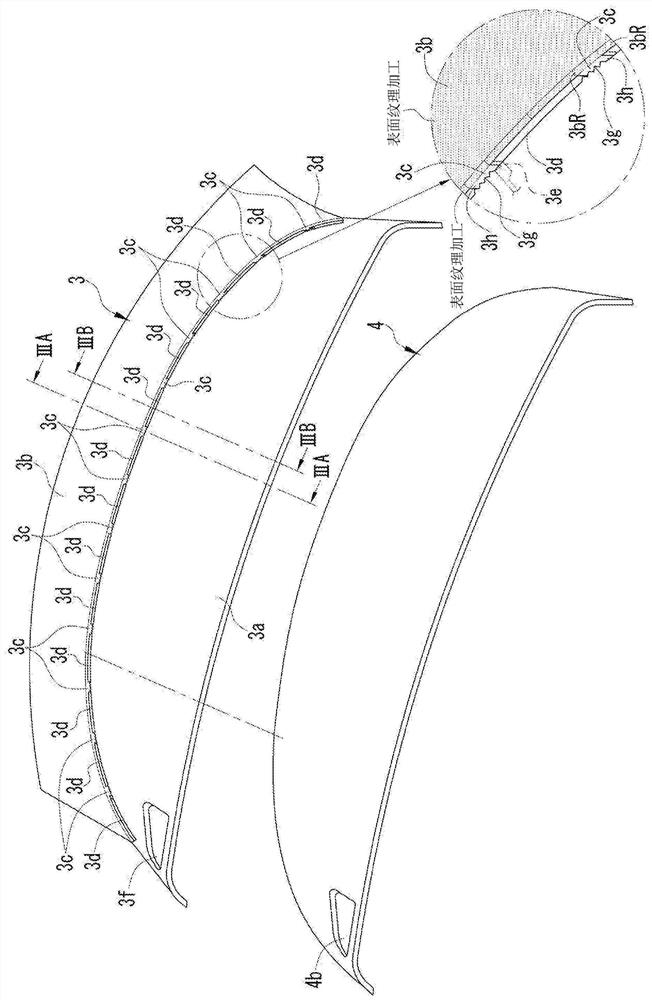

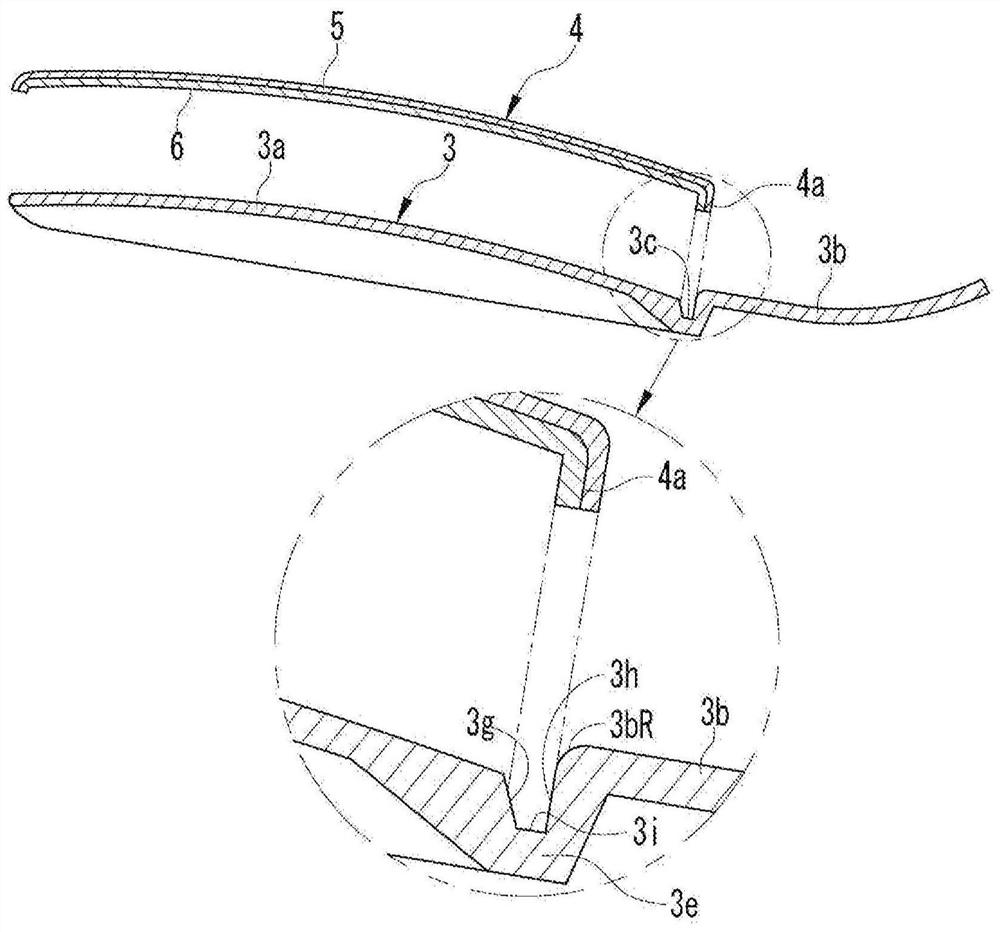

[0049] Such as figure 1 as well as figure 2 As shown, the instrument panel unit 2 is used in a vehicle, and the instrument panel unit 2 includes an instrument panel 3 (resin molded product) which is a resin molded product, and a decorative sheet 4 (attachment member) attached to the surface of the instrument panel 3 . As will be described later in detail, the decorative sheet 4 is provided with a designable sheet-shaped skin 5 and a sheet-shaped foam material 6 (refer to Figure 3A ).

[0050] A front panel 10 is attached to the instrument panel 3 . The front panel 10 is provided with an instrument display 11 for displaying instruments such as a speedometer, a tachometer, and a trip odometer, a display 12 for electronic equipment such as car navigation and audio equipment, and a display 12 for blowing air from an air conditioner (not shown). 1st - 4th air blowing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com