Control system and method for controlling amount of sludge entering furnace

A control system and sludge technology, applied in the system field, can solve the problems of entering the furnace, continuous crushing, etc., and achieve the effect of ensuring the burnout rate, improving the mixing performance and reducing the incineration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

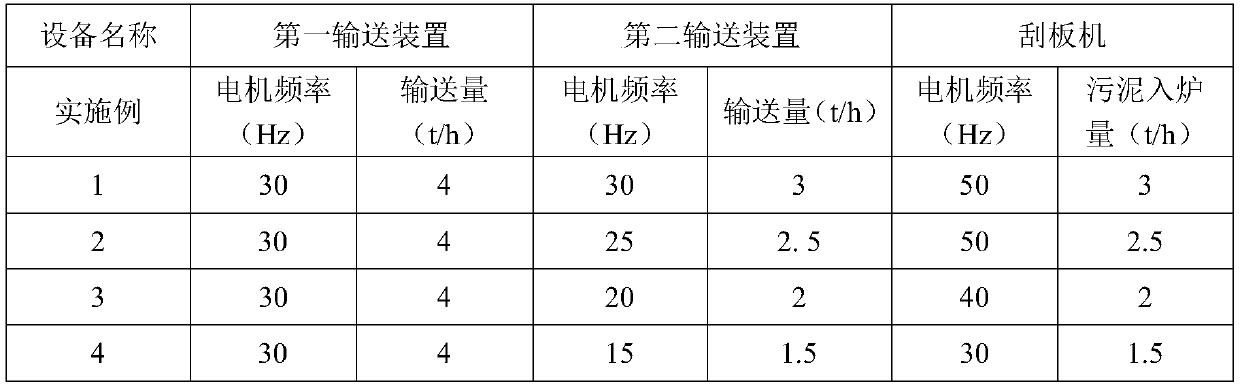

Examples

Embodiment Construction

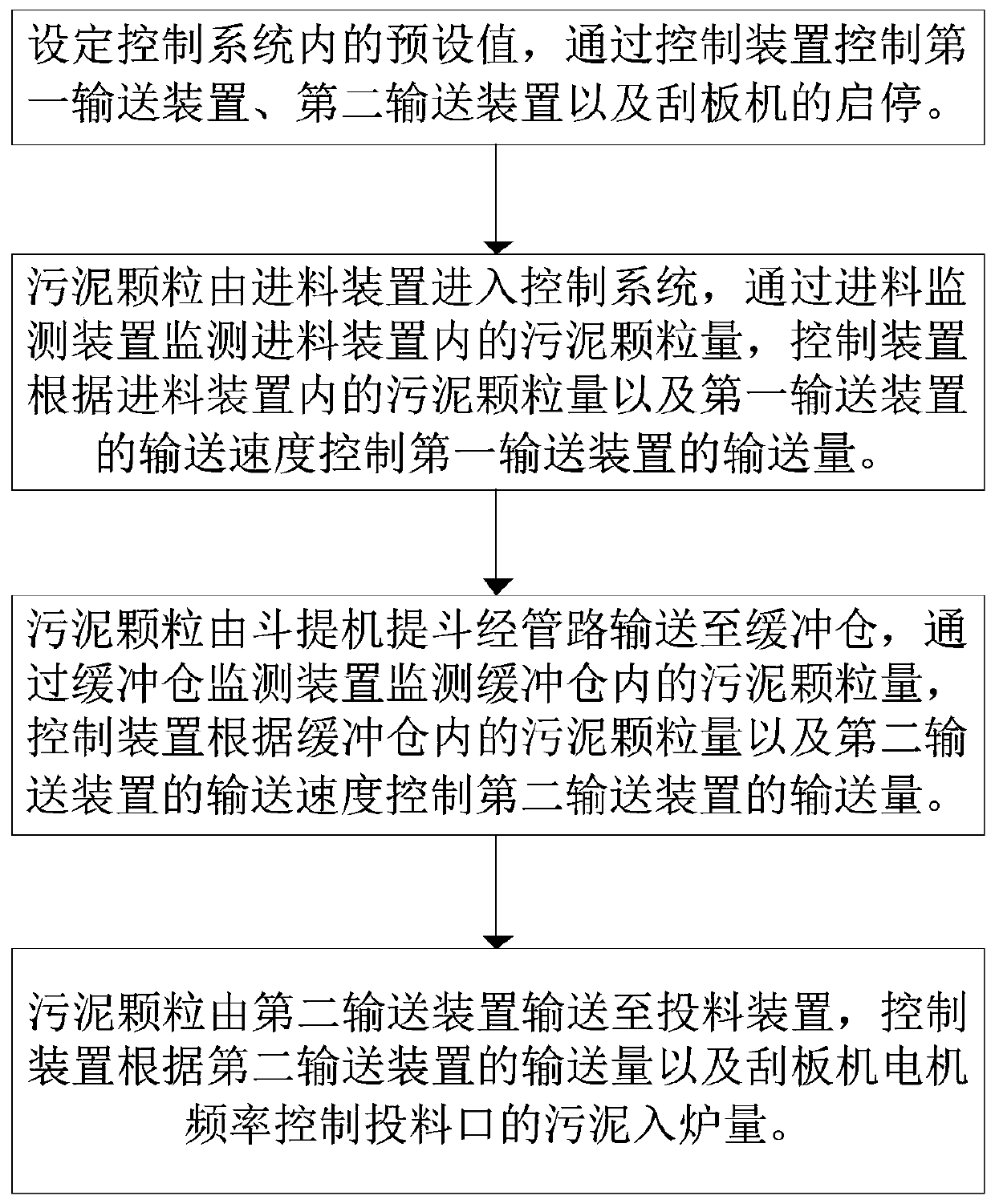

[0038] The control system and method for controlling the amount of sludge into the furnace described in the present invention will be further explained and described in conjunction with the accompanying drawings and specific examples below. However, the explanation and description do not constitute improper limitations on the technical solution of the present invention.

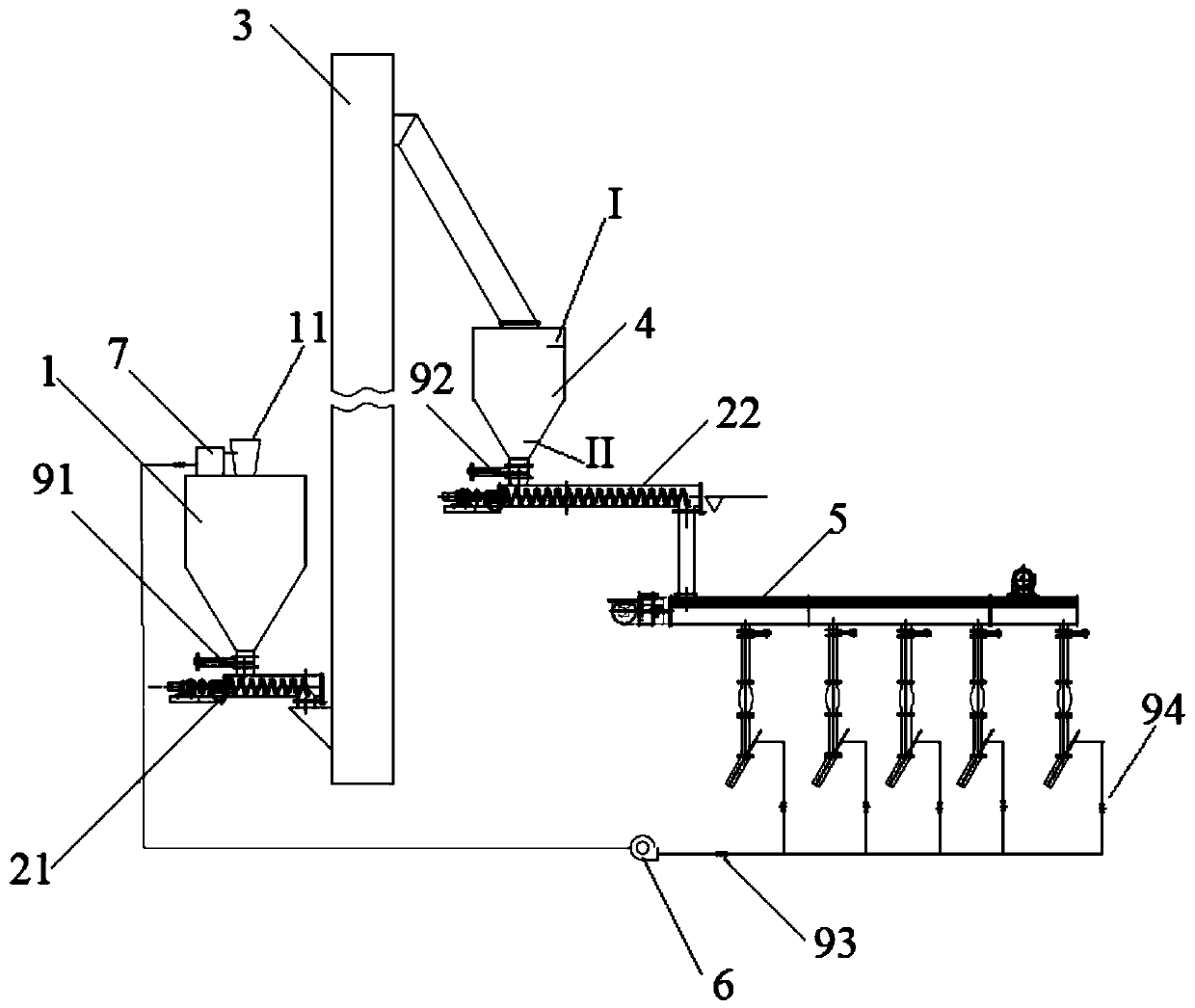

[0039] figure 1 It is a schematic diagram of the system structure in some implementations of the control system for controlling the amount of sludge entering the furnace according to the present invention.

[0040] Such as figure 1 As shown, in this embodiment, the control system for controlling the amount of sludge entering the furnace includes: feeding device 1, first conveying device 21, second conveying device 22, buffer bin 4, feeding device 5 and control device (in the figure not shown), the control device is respectively connected with the first conveying device 21, the second conveying device 22 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com