Height adjusting mechanism of sleeve penetrating type crust breaking and discharging device

A technology for shelling and cutting and height adjustment, which is applied in the field of the height adjustment mechanism of the casing penetration type shelling and cutting device, which can solve the problems of poor guiding performance, high construction cost, and large volume, and achieve good guiding performance and low construction cost. Low, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

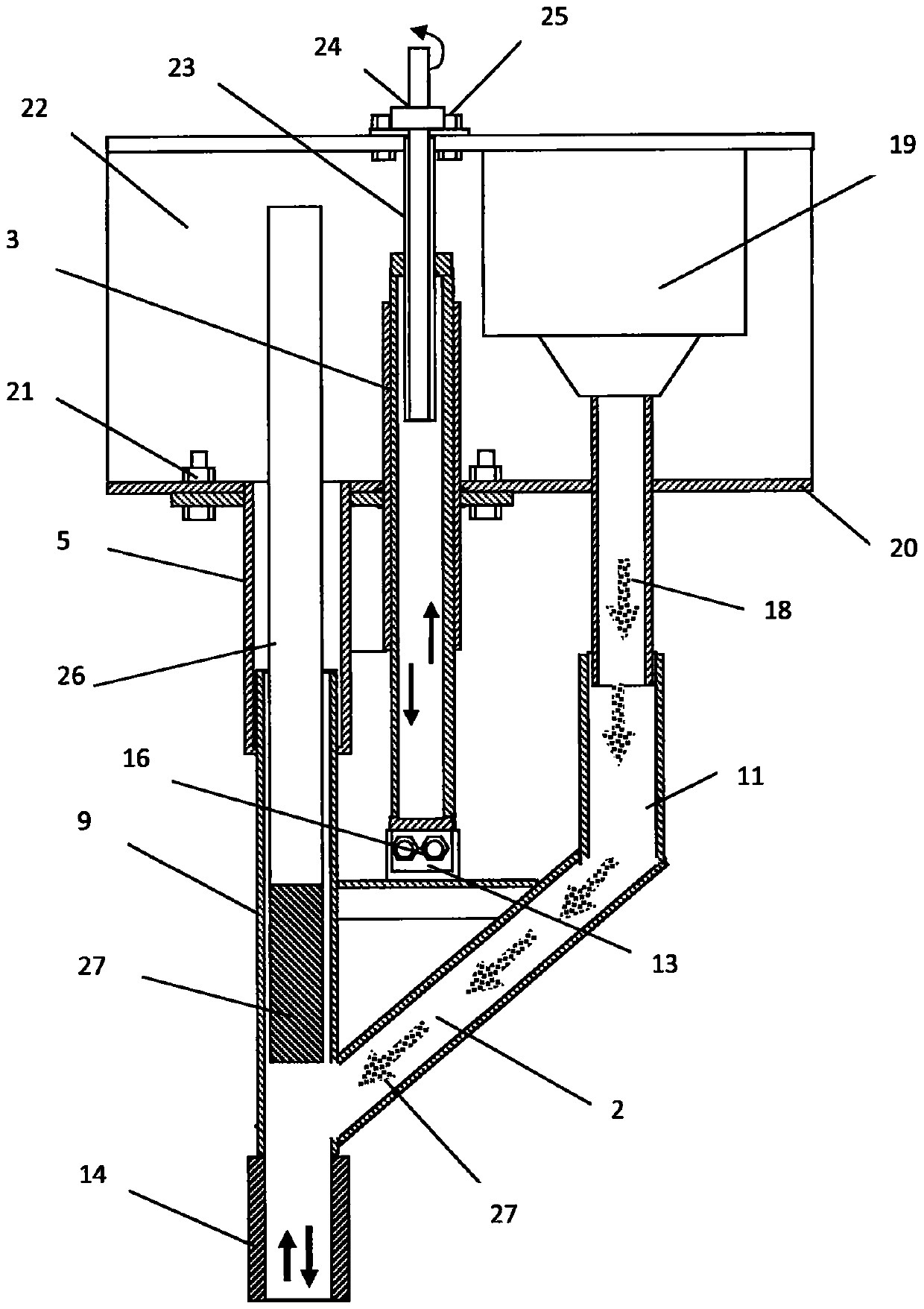

[0026] Embodiment 1: A height adjustment mechanism of a casing insertion type shelling and cutting device according to the present invention, such as figure 1 , figure 2 As shown, it is composed of the upper vertical guide device (1), the guide and discharge pipe assembly (2), and the sliding guide connection device (3).

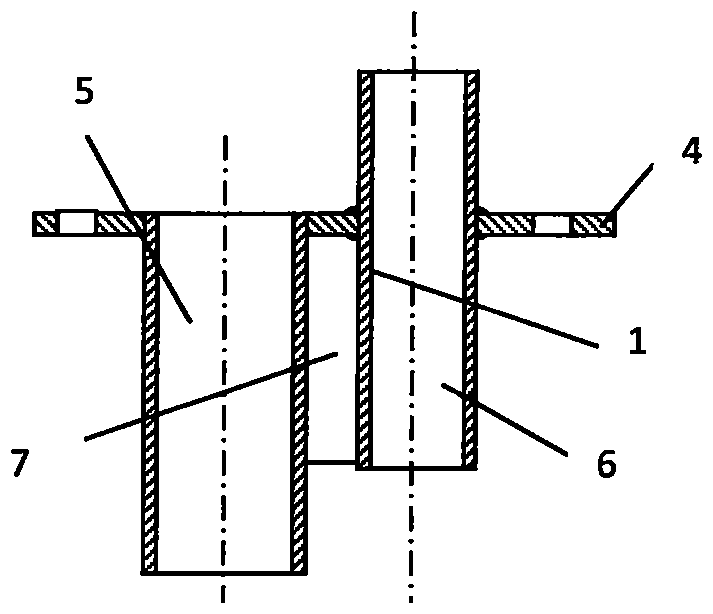

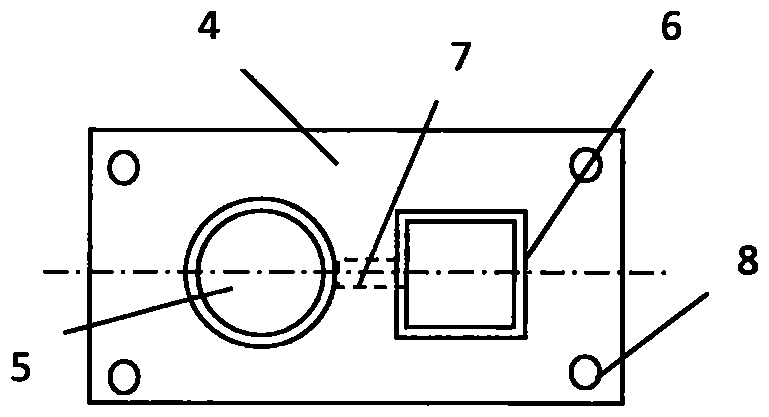

[0027] Such as figure 2 , image 3 Shown, its upper vertical guide (1) adopts welded assembly structure to form by horizontal connecting plate (4), positioning guide sleeve (5), vertical lifting guide sliding sleeve (6).

[0028] On the horizontal connecting plate (4), there are mounting bolt holes (8).

[0029] A parallel connecting plate (7) is arranged between the positioning guide pipe (5) and the vertical lifting guide sliding sleeve (6).

[0030] The inner diameter of its positioning guide sleeve (5) is slidably interspersed with the outer diameter of the shelling hammer head guide pipe (9) to connect and configure. In order to facilitate the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com