Device for improving mechanical sealing of industrial centrifugal pump

A mechanical seal and centrifugal pump technology, applied in the field of devices for improving the mechanical seal of industrial centrifugal pumps, can solve the problems of poor reliability, immature technology, high price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

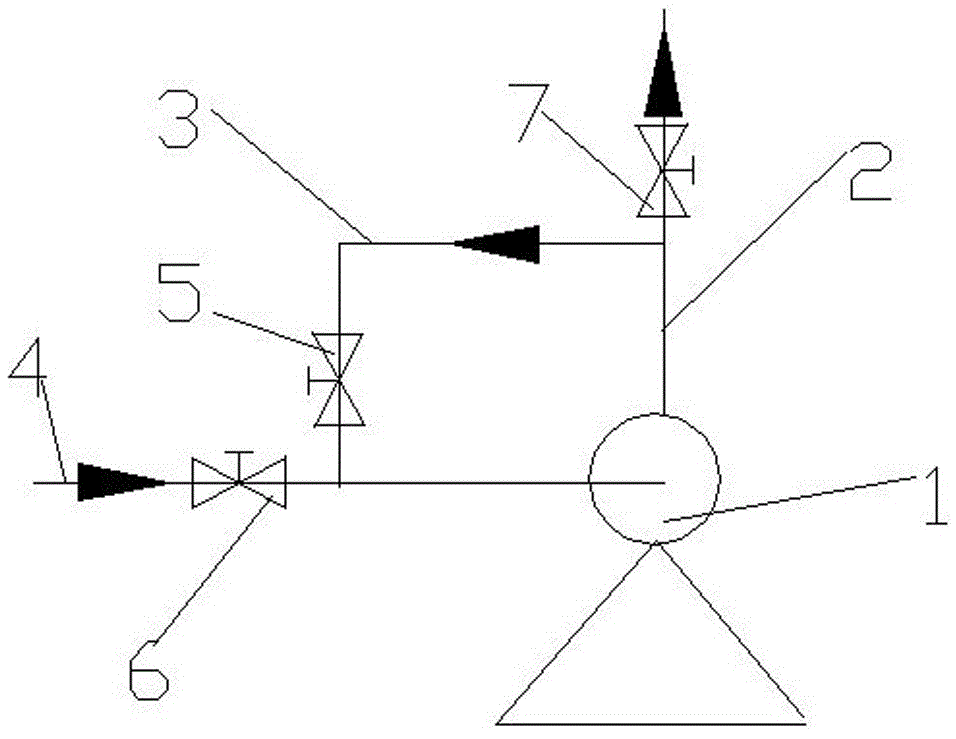

[0009] exist figure 1 Among them, a device for improving the mechanical sealing performance of a centrifugal pump, which includes a circulating process pipeline and a regulating valve, a circulating process pipeline 3 is installed between the pump outlet pipe 2 of the centrifugal pump 1 and the pump inlet pipe 4, and a regulating valve is installed on the circulating process pipeline 3 One end of the valve 5 circulation process pipeline 3 is installed behind the pump inlet valve 6, and the other end is installed in front of the pump outlet valve 7. A regulating valve 5 is installed on the circulation process pipeline 3 . When the liquid enters the pump inlet pipe, it will be discharged out of the pump outlet pipe after being processed by the centrifugal pump. The pressure at the pump outlet is greater than the pump inlet pressure. The medium in the outlet pipe enters the circulation process pipeline during the operation of the centrifugal pump and is controlled by the regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com