Method for producing stainless steel slab by radian chamfer crystallizer continuous casting machine

A chamfering crystallizer and stainless steel technology, which is applied in the field of metallurgy, can solve problems such as wide and deep slits, cracks at the edge of steel strips, affecting the yield of cold-rolled pickled plates and the utilization rate of cold-rolled plates, etc. Achieve smooth corners, eliminate edge cracks, eliminate corner cracks and sharp corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment 1, the 430 stainless steel slab in the 400 series has a thickness specification of 200mm and a width of 1520mm, and its chemical composition and mass percentage are: C: 0.061%, Si: 0.49%, Mn: 0.55%, P: 0.028 %, S: 0.003%, Cr: 16.43%, and the balance is Fe and unavoidable impurities.

[0024] A method for producing stainless steel slabs with a radian chamfering crystallizer continuous casting machine, comprising a molten iron dephosphorization process, a TSR furnace smelting process, an LF refining process, and a continuous casting process. The specific process steps are as follows:

[0025] (1) Dephosphorization process of molten iron: molten iron P: 0.126%, Si: 0.45%, adopt lime powder for dephosphorization, remove slag after dephosphorization, and after pretreatment, molten iron P: 121ppm.

[0026] (2) TSR furnace smelting process: the addition of high-carbon ferrochrome is 26.1%, dephosphorized hot metal P: 0.0121%, dephosphorized hot metal tempera...

Embodiment 2

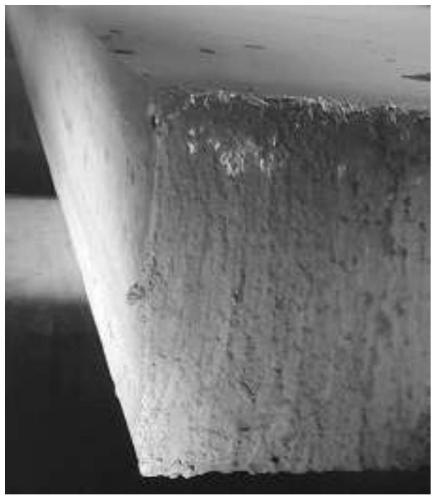

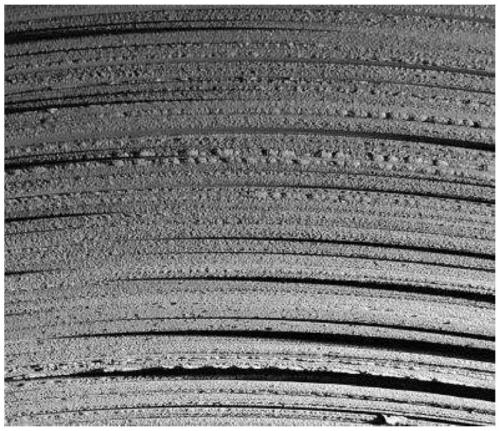

[0031] The present embodiment 2 selects the 410S steel type conventional crystallizer slab corner shape in the 400 series for use and figure 1 Similarly, the corner shape of the 410 steel grade chamfering crystallizer slab is the same as figure 2 Similarly, the shape of the edge of the 410 steel conventional mold slab after hot rolling is the same as image 3 Similarly, the shape of the rear edge of the 410 steel chamfering crystallizer slab after hot rolling is the same as Figure 4 Similarly, the slit line and the Figure 5 Similarly, 410 steel grade chamfering crystallizer slab hot-rolled pickling after slit line and Image 6 It is similar, so the drawings corresponding to Embodiment 2 are omitted.

[0032] In this example, the 410S stainless steel slab has a thickness specification of 200mm and a width of 1520mm, and its chemical composition and mass percentage are: C: 0.045%, Si: 0.52%, Mn: 0.22%, P: 0.035%, S: 0.002% , Cr: 12.55%, the balance is Fe and unavoidable i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com