Grease degradation complex microbial inoculant as well as preparation method and application thereof

A technology of compound bacterial agent and oil, which is applied in the direction of biochemical equipment and methods, chemical instruments and methods, and methods based on microorganisms, etc. It can solve the problems of oil pollution and other problems, and achieve the effect of stable performance, reasonable formula and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

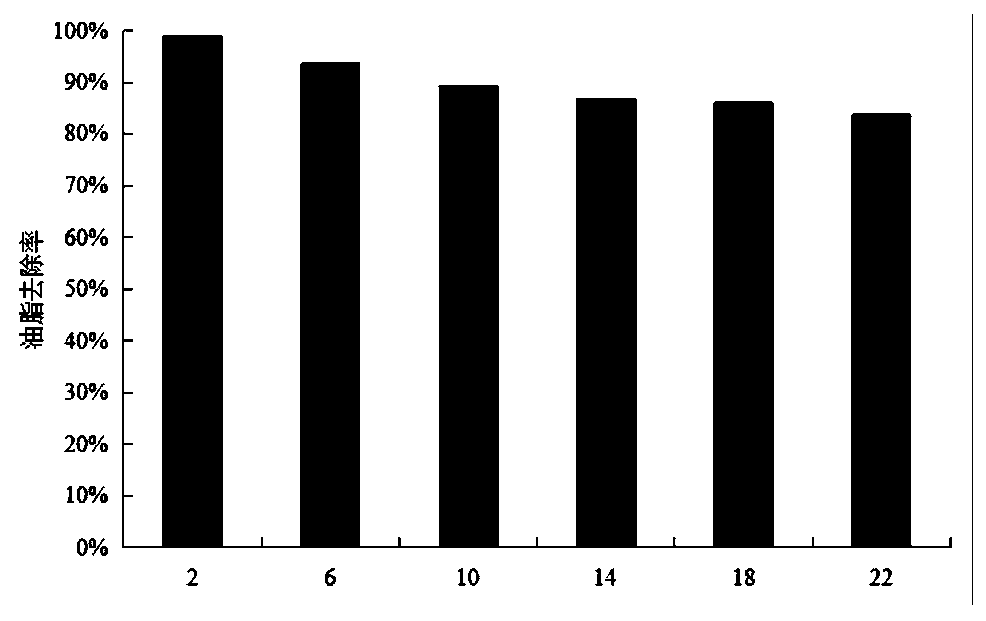

[0045] Embodiment 1 Grease degrading bacterial agent of the present invention is applied to the grease waste water of different concentration

[0046] Follow the steps below:

[0047] 1. Preparation of oil-degrading bacterial agent

[0048] Inoculate Bacillus subtilis, Bacillus amyloliquefaciens, and Klebsiella mutans into beef extract peptone medium for seed preparation, culture for 2-3 days, and after the growth of the bacteria is stable, divide the bacteria according to Bacillus subtilis, Bacillus amyloliquefaciens bacillus and Klebsiella mutabilis seed solution (volume fraction, V / V) at a ratio of 5:2:3, further inoculated in QMM medium for seed expansion cultivation, so that the total number of effective viable bacteria was 2.5×10 9 CFU / mL, to obtain the oil-degrading compound bacterial agent.

[0049] 2. Simulated wastewater experiments with different oil concentrations

[0050] Using soybean oil as the main raw material, the oil-degrading composite bacterial agent wa...

Embodiment 2

[0051] Example 2 Grease Degradation Bacteria Applied to Grease Wastewater with Different pH

[0052] Follow the steps below:

[0053] 1. Preparation of oil-degrading compound bacterial agent:

[0054] 2. Inoculate Bacillus subtilis, Bacillus amyloliquefaciens, Klebsiella mutans, Citrobacter, Pseudomonas stutzeri, Pseudomonas fluorescens, Lactobacillus casei and Saccharomyces cerevisiae into beef extract peptone culture Prepare the seeds in the culture medium and culture them for 2-3 days. After the growth of the bacteria is stable, the ratio of the seed liquid (V / V) of the above strains is 6:1:4:3:6:8:2:4, and then inoculate in QMM The medium is used for seed expansion cultivation, and a stable culture solution is obtained after two-level seed expansion cultivation, so that the total number of effective viable bacteria is 5×10 9 CFU / mL, to obtain the oil-degrading compound bacterial agent.

[0055] 3. Grease-degrading bacterial agents treat grease wastewater with different ...

Embodiment 3

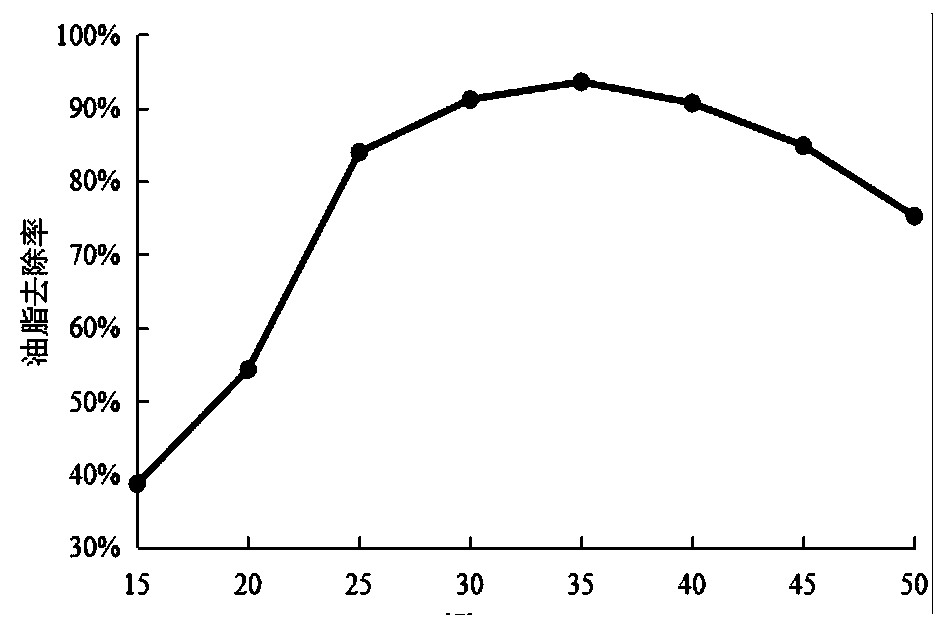

[0057] Embodiment 3 Grease degrading bacterial agent is to the adaptation range of temperature

[0058] Follow the steps below:

[0059] 1. Preparation of oil-degrading compound bacterial agent:

[0060] Inoculate Bacillus subtilis, Bacillus amyloliquefaciens, Klebsiella mutans, Citrobacter, Pseudomonas stutzeri, Pseudomonas fluorescens, Lactobacillus casei and Saccharomyces cerevisiae into beef extract peptone medium Carry out seed preparation and culture for 2-3 days. After the growth of the strain is stable, the ratio of the seed solution (V / V) of the above strain is 1:4:3:1:6:8:2:1, and further inoculated in QMM medium Carry out seed expansion cultivation, obtain a stable culture medium after 2-level seed expansion cultivation, and adjust the OD of the bacterial suspension 600 is 0.8±0.1, and the oil-degrading composite bacterial agent is obtained.

[0061] 2. The removal rate of grease degrading bacteria agent at different temperatures:

[0062] Using soybean oil as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com