Cleaning agent for electrification maintenance and using method thereof

A cleaning agent and compound antistatic agent technology, applied in the field of cleaning agents, can solve the problems of equipment loss of insulation, equipment surface corrosion, narrow application range, etc., achieve a huge implementation and application range and market promotion value, reduce maintenance costs, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

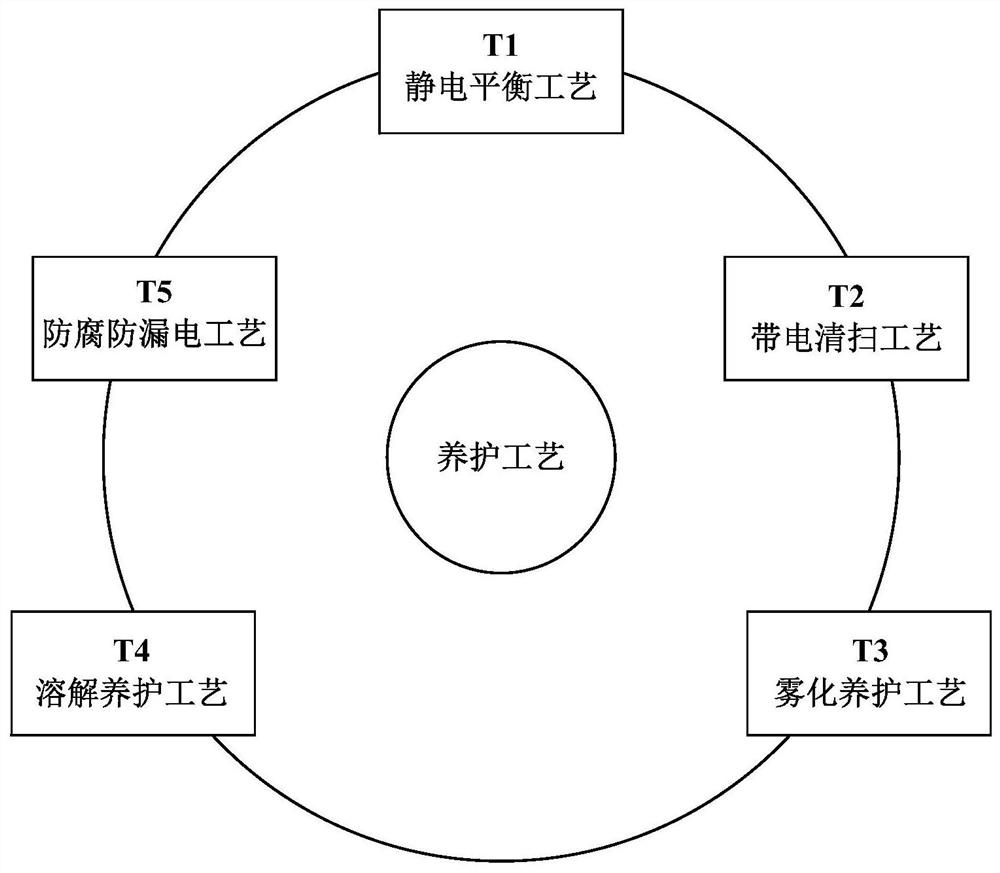

Method used

Image

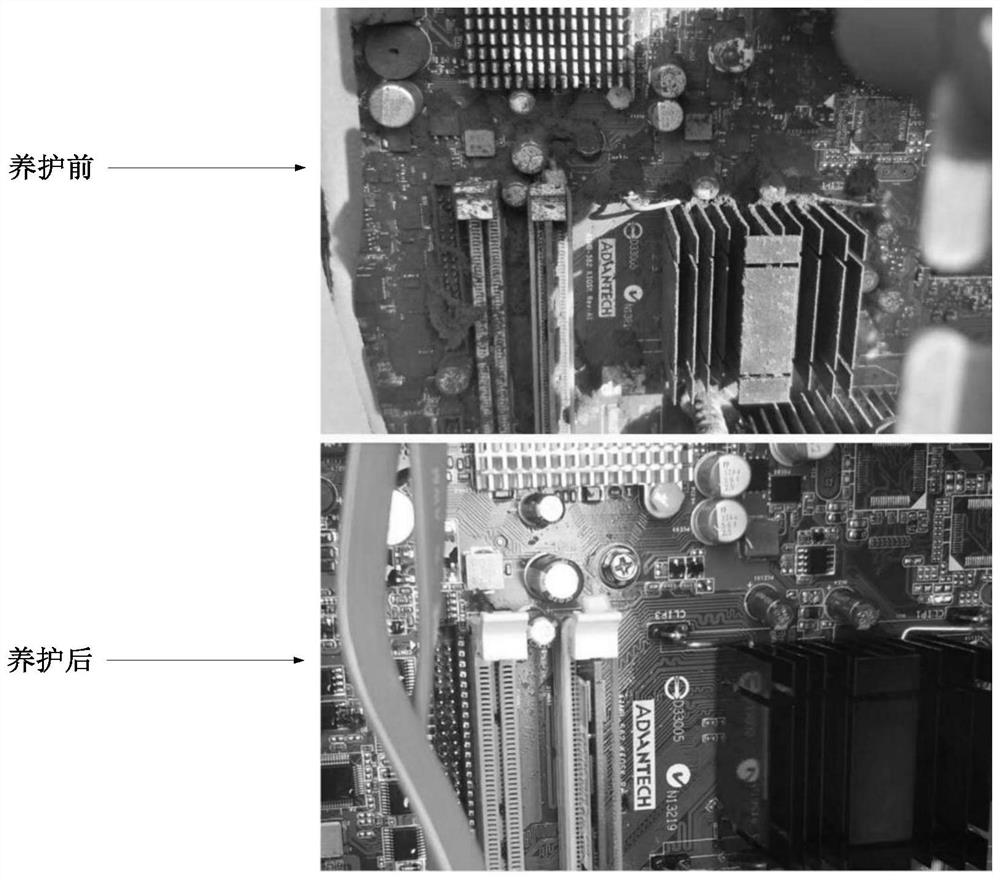

Examples

Embodiment 1

[0051] The cleaning agent for electrification maintenance is prepared from the following formula:

[0052] 90 parts by weight of a compounded hydrocarbon solvent, 2 parts by weight of a compounded antistatic agent, 3 parts by weight of a compounded penetration aid, and 8 parts by weight of a compounded cleaning aid.

[0053] (1) Compound hydrocarbon solvent formula:

[0054] The compound hydrocarbon solvent is composed of 75% by weight of C9-C12 alkane hydrocarbon solvent and 25% by weight of flame retardant, wherein, the weight ratio of normal paraffin in C9-C12 alkane hydrocarbon solvent: isoparaffin The ratio is 3:1, and the flame retardant is hexabromocyclohexane.

[0055] (2) Formula of compound antistatic agent:

[0056] The weight ratio of fatty acid polyol ester: diethanolamide: sorbitol in the compound antistatic agent is 8:5:2.

[0057] (3) Formula of compound penetration aid:

[0058] The compound penetration aid consists of 36% by weight of fatty alcohol polyoxye...

Embodiment 2

[0063] The cleaning agent for electrification maintenance is prepared from the following formula:

[0064] 95 parts by weight of a compounded hydrocarbon solvent, 3 parts by weight of a compounded antistatic agent, 3 parts by weight of a compounded penetration aid and 9 parts by weight of a compounded cleaning aid.

[0065] (1) Compound hydrocarbon solvent formula:

[0066] The compound hydrocarbon solvent is composed of 75% by weight of C9-C12 alkane hydrocarbon solvent and 25% by weight of flame retardant, wherein, the weight ratio of normal paraffin in C9-C12 alkane hydrocarbon solvent: isoparaffin The weight ratio of hexabromocyclohexane:n-bromopropane in the flame retardant is 5:3.

[0067] (2) Formula of compound antistatic agent:

[0068] The weight ratio of fatty acid polyol ester: diethanolamide: sorbitol in the compound antistatic agent is 8:3:2.

[0069] (3) Formula of compound penetration aid:

[0070] The compound penetration aid consists of 35% by weight of f...

Embodiment 3

[0075] The cleaning agent for electrification maintenance is prepared from the following formula:

[0076] 95 parts by weight of a compounded hydrocarbon solvent, 2 parts by weight of a compounded antistatic agent, 3 parts by weight of a compounded penetration aid, and 7 parts by weight of a compounded cleaning aid.

[0077] (1) Compound hydrocarbon solvent formula:

[0078] The compound hydrocarbon solvent is composed of 75% by weight of C9-C12 alkane hydrocarbon solvent and 25% by weight of flame retardant, wherein, the weight ratio of normal paraffin in C9-C12 alkane hydrocarbon solvent: isoparaffin The weight ratio of hexabromocyclohexane:n-bromopropane in the flame retardant is 5:3.

[0079] (2) Formula of compound antistatic agent:

[0080] The weight ratio of fatty acid polyol ester: diethanolamide: sorbitol in the compound antistatic agent is 8:3:2.

[0081] (3) Formula of compound penetration aid:

[0082] The compound penetration aid consists of 35% by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com