Yogurt composition with whipping and decorating performance, yogurt product, preparation method and application

A technology of composition and dairy products, which is applied in the field of dairy food, can solve the problems of baking, mounting, and fermented yogurt with short shelf life in refrigerated storage and transportation, and achieve industrial commercialization to generate market value and rich in probiotics. Bacteria, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

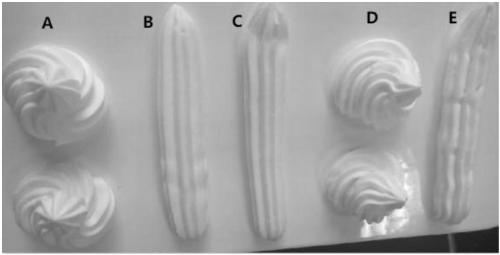

Image

Examples

preparation example Construction

[0047] As mentioned above, the present invention provides a yoghurt with whipped decorating performance and its preparation method and application. The yoghurt is made by adding specific additives in the process of fermenting the yoghurt, so that the low-fat yoghurt rich in probiotics and having multiple health functions has the performance of whipping and decorating. The protein content of the yogurt is 2.8-3.0%; the fat content is 5-7%; the probiotic content is ≥1.0*10 6 / g.

[0048] Among them, in a more preferred embodiment of the present invention: a composition of whipped yogurt is provided, including milk raw materials, cream, leavening agent and thickener.

[0049] Preferably, wherein, the composition further includes an emulsifier, protein powder, and a sweetener; preferably, the sweetener includes a first sweetener and a second sweetener.

[0050] Preferably, wherein, based on the weight ratio in the composition, the content of the cream is 1-8.4%, the content of t...

Embodiment 1

[0091] 1. Raw material formula:

[0092] Table 3 Embodiment 1 raw material formula table

[0093]

[0094]

[0095] 2. Preparation method:

[0096] Step 1: 80g white sugar; 30g cream; 4g whey protein powder WPC80; second sweetener: 0.2g aspartame; thickener: 18g hydroxypropyl distarch phosphate, 7g gelatin, 3.5g Agar, 1g pectin; emulsifier: 2g lactic acid fatty acid glycerides, 2g diacetyl tartaric acid mono-diglycerides were pre-mixed in a 1000mL large flask, added to 800g fresh milk, kept at 80°C for 15 minutes, cooled to 2°C, Add 52.3g of purified water to make up to volume.

[0097] Step 2: Put the mixed liquid in the above flask into a homogenizer for homogenization treatment, the homogenization temperature is 50°C, and the homogenization pressure is 18MPa, and then put the collected homogeneous liquid into a plate sterilizer for disinfection For treatment, the disinfection temperature is 90°C, and the disinfection time is 300 seconds.

[0098] Step 3: Lower the...

Embodiment 2

[0100] 1. Raw material formula:

[0101] Table 4 Embodiment 2 raw material formula table

[0102]

[0103]

[0104] 2. Preparation method:

[0105] Step 1: Mix 140g whole milk powder, 40g white sugar; 60g cream; 10g anhydrous cream; 2g whey protein powder WPC80; second sweetener: 0.15g aspartame, 0.15g acesulfame potassium; thicken Agent: 18g hydroxypropyl distarch phosphate, 7g gelatin, 4g agar, 1g pectin; emulsifier: 1g lactic acid fatty acid glycerides, 1g diacetyl tartaric acid mono-diglycerides pre-mixed in a 1000mL large flask, 60 ℃ circulation insulation After 30 minutes, the temperature was lowered to 10°C, and 715.7 g of pure water was added to make up to volume.

[0106] Step 2: Put the mixed liquid in the above flask into a homogenizer for homogenization treatment, the homogenization temperature is 70°C, and the homogenization pressure is 22MPa, and then put the collected homogeneous liquid into a plate sterilizer for disinfection treatment, the disinfectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com