Highway tunnel electromechanical equipment monitoring system and method

A technology for electromechanical equipment and road tunnels, which is applied in the field of monitoring systems for electromechanical equipment in highway tunnels, can solve problems such as inconvenient management for managers, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

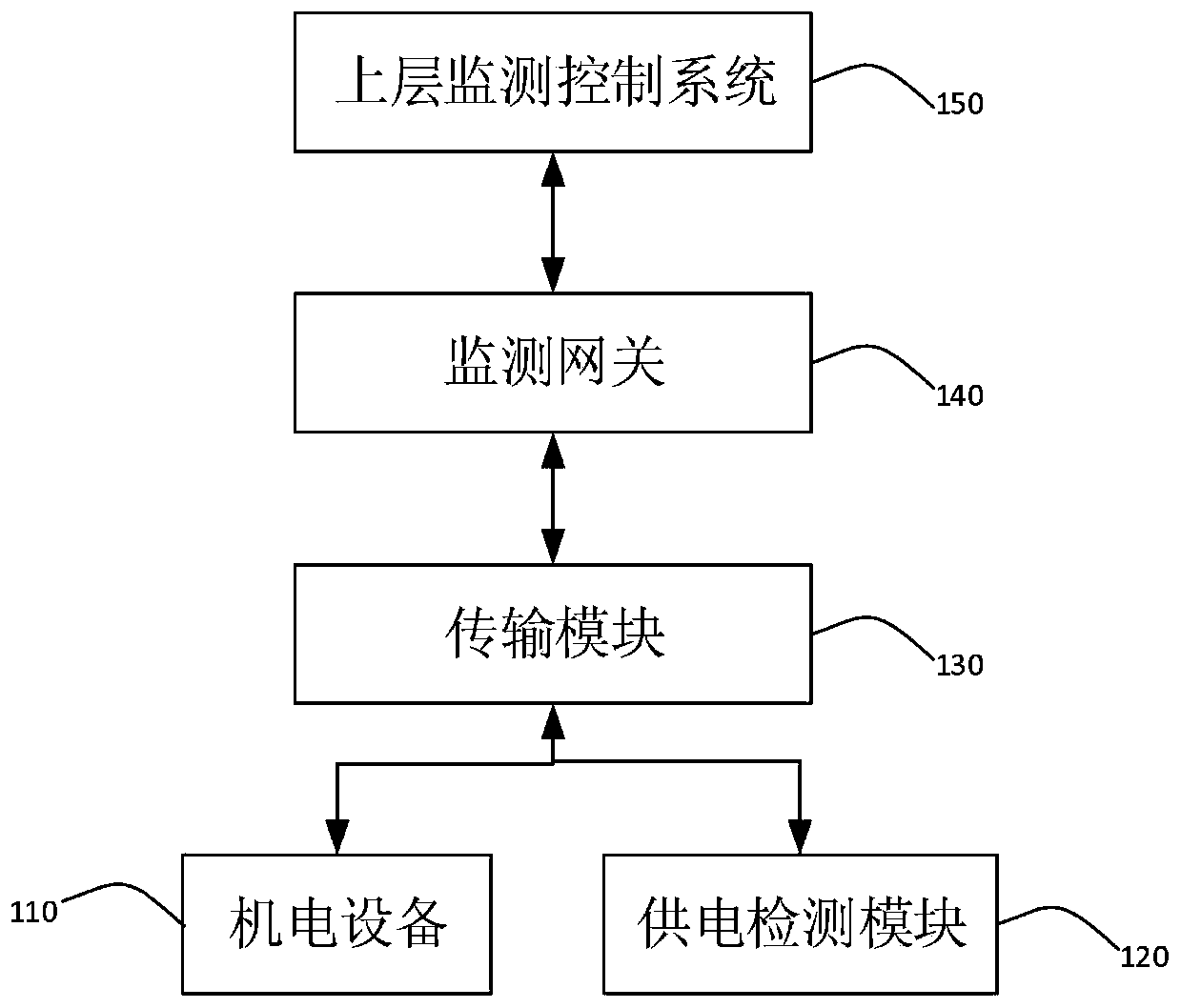

[0032] Please refer to the attached figure 1 , the present invention provides a highway tunnel electromechanical equipment monitoring system, including: electromechanical equipment 110, power supply detection module 120, transmission module 130, monitoring gateway 140 and upper monitoring control system 150; wherein, electromechanical equipment 110 is set in the tunnel, each A power supply detection module 120 is placed in the power supply control cabinet of each electromechanical device 110, and the transmission module 130 is connected to the electromechanical device 110 and the power supply detection module 120 respectively, and the transmission module 130 is set in one-to-one correspondence with the monitoring gateway 140, and communicates with the monitoring gateway 140 Connection; the monitoring gateway 140 is set in the tunnel, monitors all electromechanical equipment 110 in the network, and reports the monitoring information to the upper monitoring control system 150; th...

Embodiment 2

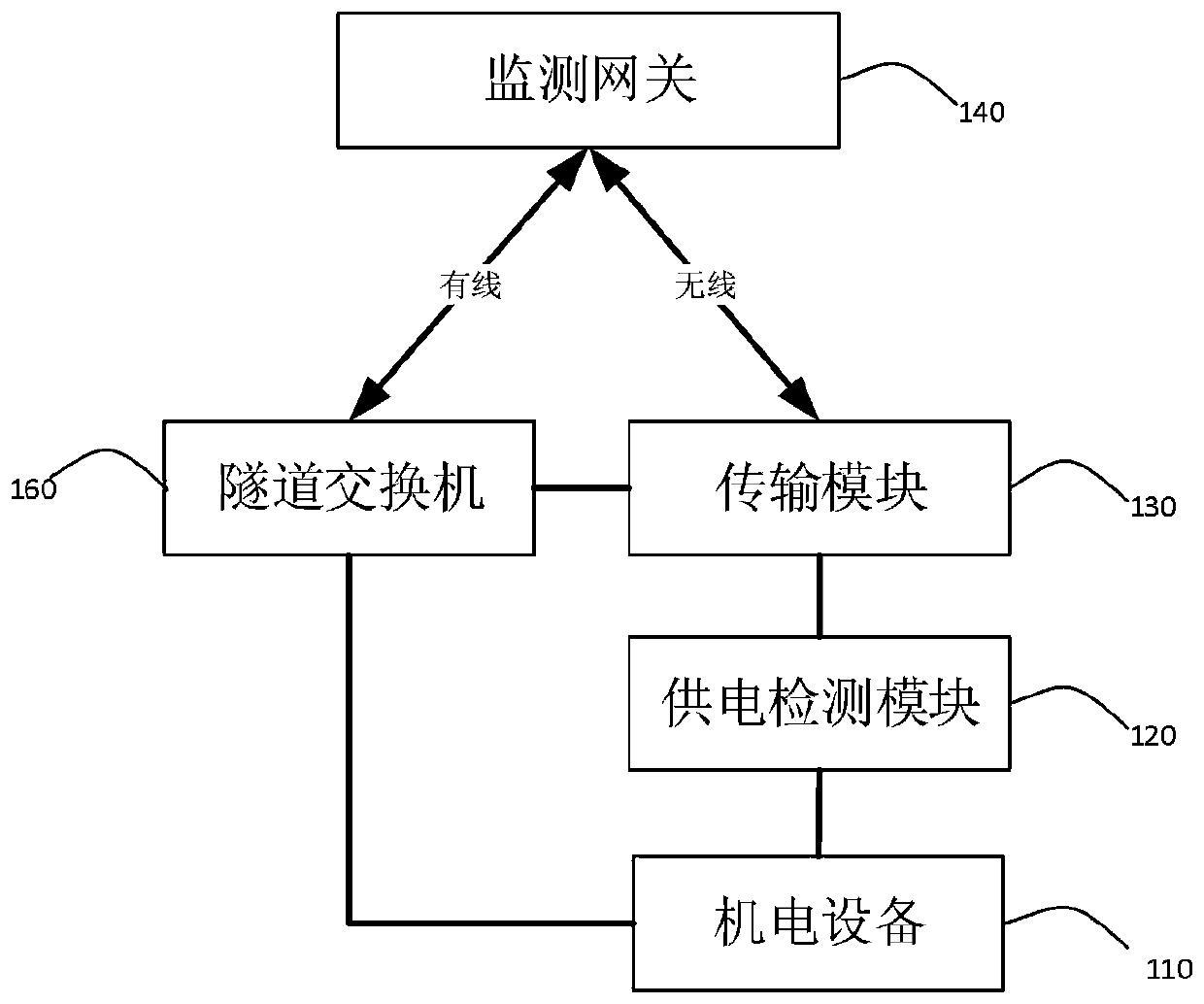

[0040] Such as figure 2As shown, this embodiment provides a highway tunnel electromechanical equipment monitoring system. On the basis of Embodiment 1, the present invention also includes a tunnel switch 160, which is connected to the transmission module 130, and the tunnel switch 160 passes through the transmission module 130. The wireless network communicates data with the monitoring gateway 140 . The power supply detection module 120 realizes the current and voltage monitoring of the electromechanical equipment 110, and is connected with the tunnel switch 160 through the transmission module 130, and realizes data communication with the monitoring gateway 140 through the tunnel wired network.

[0041] In order to further optimize the above technical solution, if the tunnel switch 160 is disconnected from the wired network in the tunnel, the tunnel switch 160 communicates with the monitoring gateway 140 via the mobile wireless network through the transmission module 130 . T...

Embodiment 3

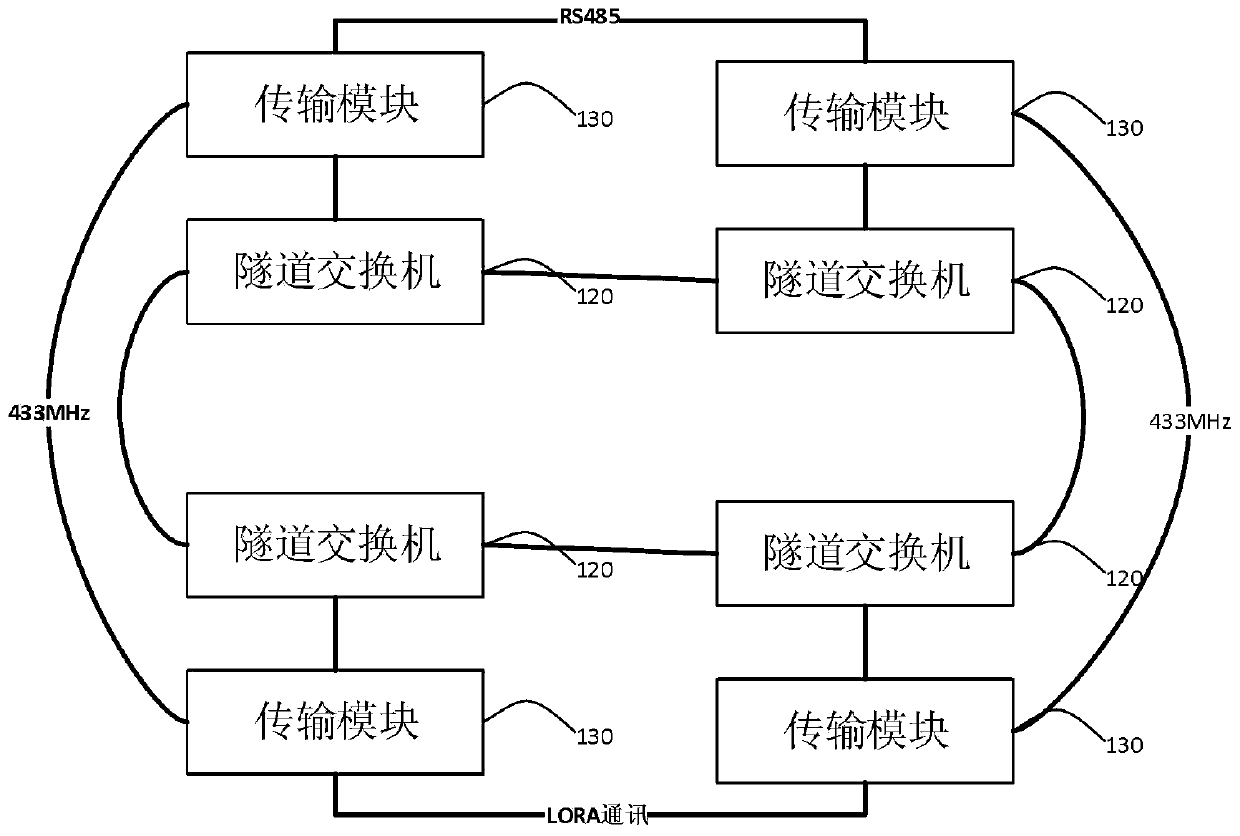

[0045] Such as image 3 As shown, this embodiment provides a highway tunnel electromechanical equipment monitoring system. On the basis of Embodiment 2, the power supply detection modules 120 are networked with each other through various communication methods, and the established network links become the tunnel ring network. Backup link.

[0046] In order to further optimize the above technical solution, if the distance between the two power supply detection modules 120 is within 10 meters, or if there is a physical barrier between the two power supply detection modules 120, RS485 communication is used to realize data communication.

[0047] In order to further optimize the above technical solution, the power supply detection modules 120 on both sides of the tunnel entrance can directly use 433MHz wireless communication to realize data communication, saving the need for wired wiring and the implementation risk of crossing the highway.

[0048] In order to further optimize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com