Steel-wood composite shock-isolation pad foundation and its installation method

A technology of steel-wood combination and vibration-isolation pad, which is applied in the direction of basic structure engineering, earthquake-proof, building type, etc., can solve the problems of affecting the safety of vibration-isolation bearings, no vibration reduction effect, complicated installation process, etc., and achieve good reset effect, Good anti-seismic effect and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

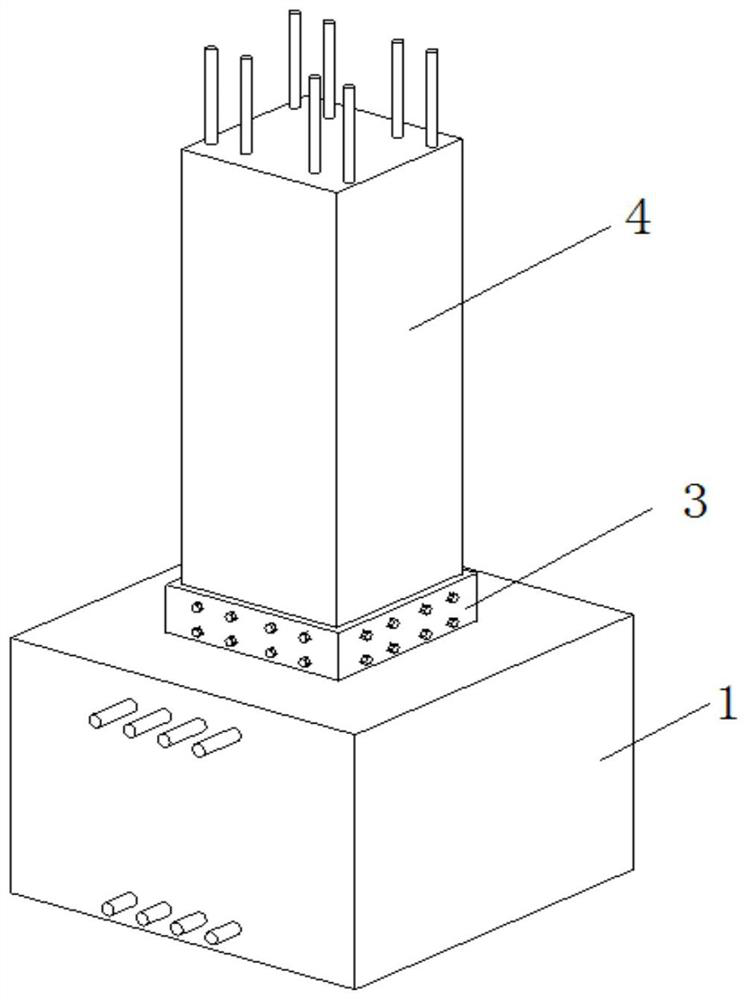

[0045] Such as figure 1 As shown, the steel-wood composite seismic pad foundation of the present invention comprises a reinforced concrete foundation 1, a composite seismic pad 2, a steel sleeve 3 and a wooden column 4;

[0046] The reinforced concrete foundation 1 is a concrete cast-in-place structure, including a lower foundation 11 and an upper foundation 12,

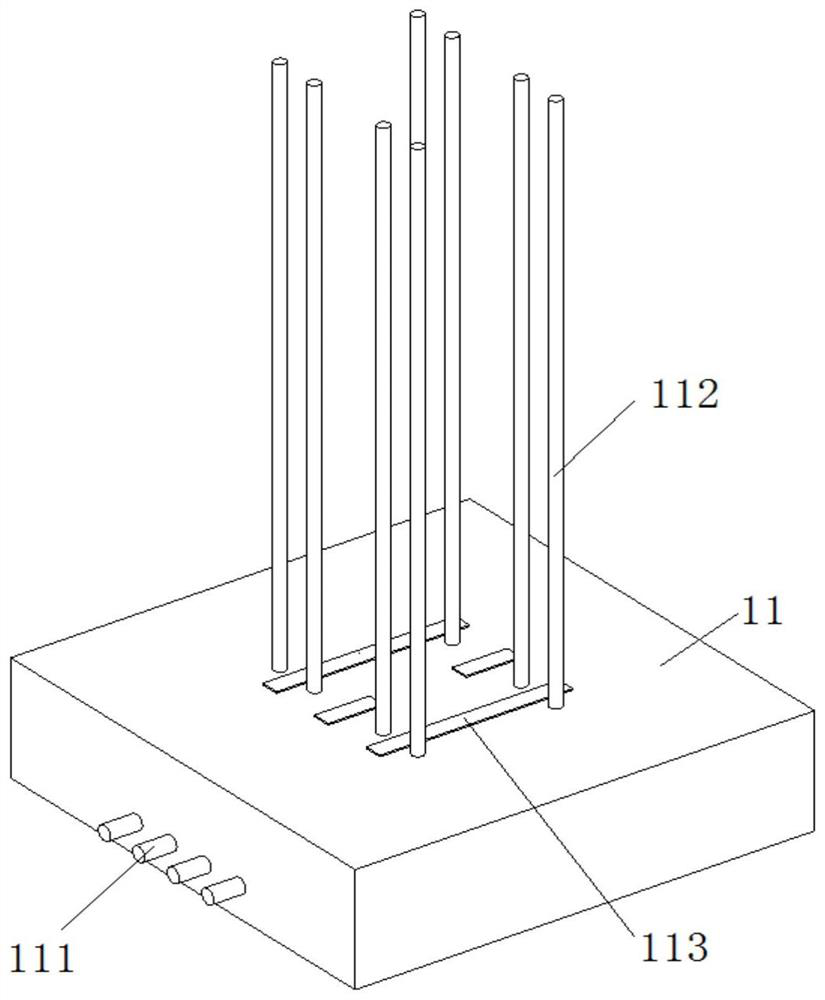

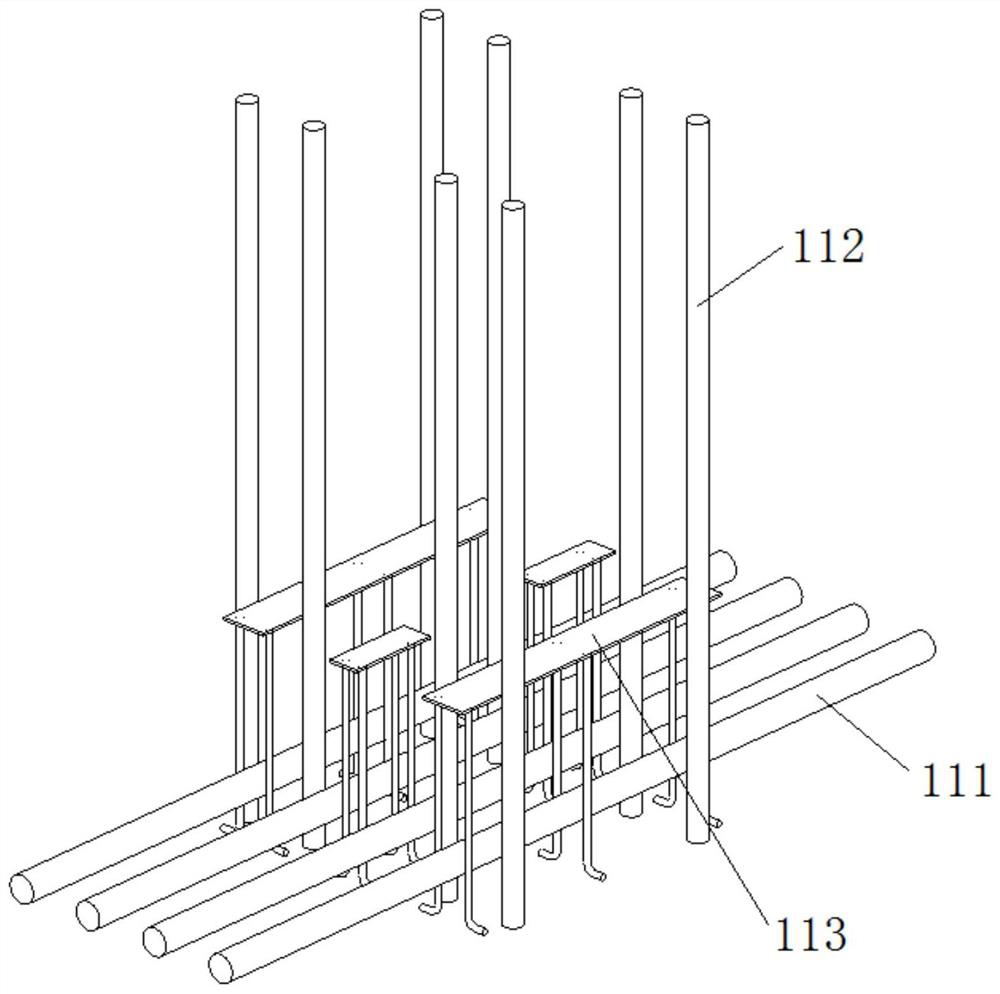

[0047] Such as Figure 2-4 As shown, the lower foundation 11 is provided with a number of horizontal steel bars I111 parallel to each other, vertical steel bars 112 and steel bar embedded parts 113, and the steel bar embedded parts include horizontal plates 1131 and π-shaped steel bars 1132 fixed on the horizontal plates, each There are 2-3 sets of π-shaped steel bars 1132 on the steel bar embedded parts, each group of π-shaped steel bars 1132 includes two symmetrical L-shaped steel bars, and the horizontal stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com