Method for modifying interfacial properties of transformer oil paper and nano-modified transformer oil paper

A transformer oil and nano-modification technology, applied in the direction of transformer/inductor coil/winding/connection, paper, papermaking, etc., can solve the problem of low insulation performance of composite media, achieve low insulation performance and ease the dielectric constant The difference, the effect of changing the propagation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This implementation discloses a method for modifying the interface performance of transformer oil paper, which includes the following steps:

[0032] Dispersed and added spherical TiO to the interface between transformer oil and insulating oil paper in the transformer 2 Nanoparticles or Fe 3 o 4 Nanoparticles, the diameter of the nanoparticles is 20-100nm.

[0033] The method for modifying the performance of the transformer oil-paper interface in the present invention suppresses the accumulation of space charges at the oil-paper interface by dispersing nanoparticles at the oil-paper interface, alleviates the difference in dielectric constant between the transformer oil and the oil-immersed paperboard, and then changes the discharge at the oil-paper interface. The transmission characteristics at the interface improve the flashover performance of the transformer oil-paper interface, thereby solving the technical problem of low insulation performance of the existing tran...

Embodiment 2

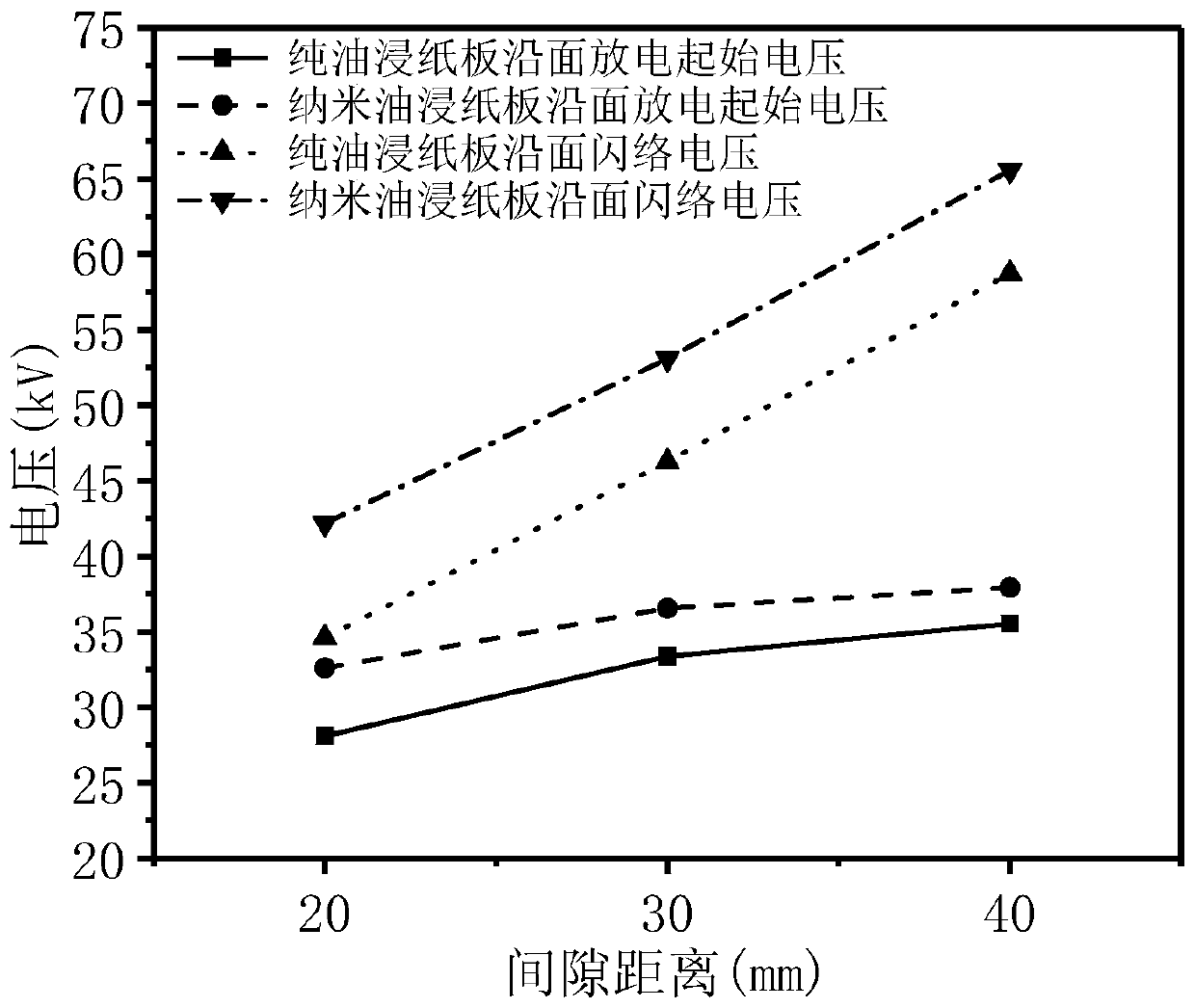

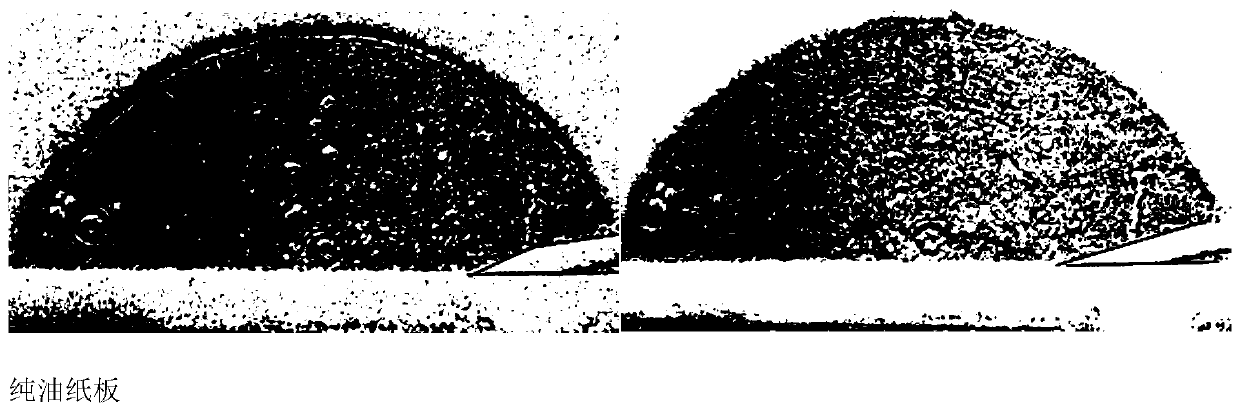

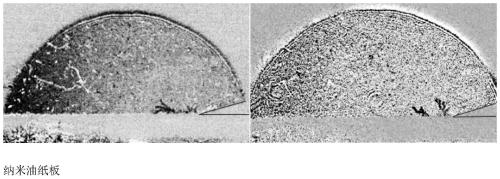

[0037] In order to verify the superiority of the method for modifying the interface performance of transformer oil-paper in the present invention and the insulation performance of nano-modified transformer oil-paper, a pure oil-immersed (pure transformer oil) cardboard was prepared to be used together with nano-modified transformer oil-paper in the present invention. Carry out insulation performance control test, the specific content is as follows:

[0038] (1) Preparation of pure oil-impregnated paperboard and nano-oil-impregnated paperboard (i.e. nano-modified transformer oil paper):

[0039] The transformer oil used in this paper is Karamay 25# transformer oil. After filtration, the particle impurity content in the oil meets the standards set by the CIGRE (International Conference on Large Power Grids) working group, and pure transformer oil (abbreviated as pure oil) is obtained. A certain amount of semiconducting TiO 2 The nanoparticles are uniformly dispersed in the pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com