Preparation method of calcium carbonate filled high-strength coated paper

A technology of calcium carbonate and coated paper, which is applied in the field of papermaking, can solve the problems of reducing the strength of coated paper, destroying the hydrogen bond force of plant fibers, etc., and achieve the effect of reducing raw material costs and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

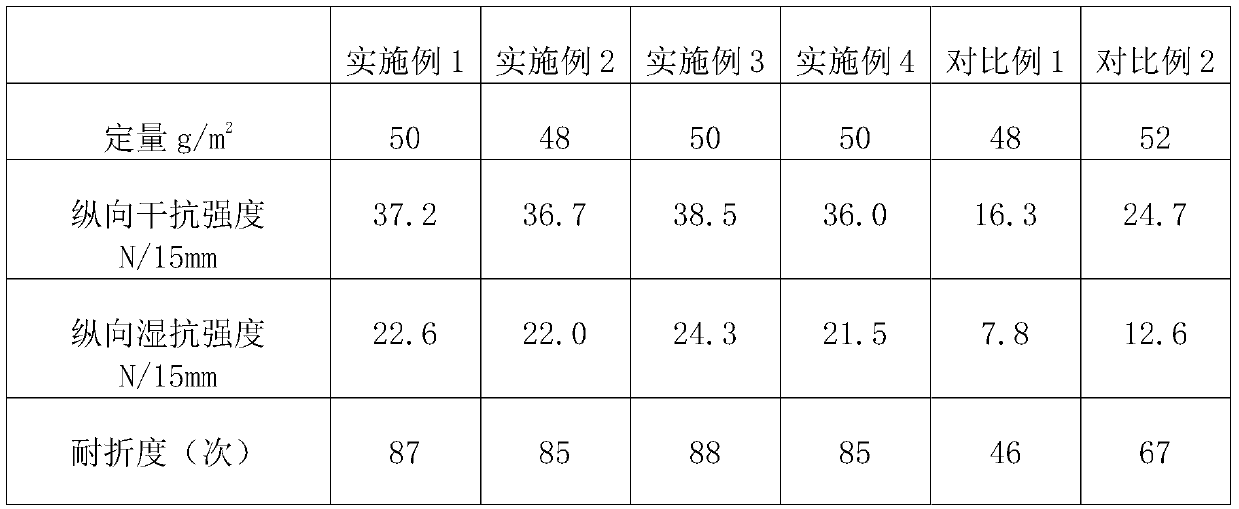

Examples

Embodiment 1

[0029]The pretreatment method of calcium carbonate powder comprises the following steps:

[0030] Add the silane coupling agent KH550 into deionized water and stir to dissolve to obtain a silane coupling agent solution with a mass concentration of 2%. According to the ratio of calcium carbonate to silane coupling agent mass ratio of 1:0.2, add calcium carbonate powder to the silane coupling agent solution, heated to 60°C in a water bath, kept stirring for 1 hour, filtered and separated, and the product obtained by the reaction was added to a carboxymethyl cellulose solution with a mass concentration of 6.0 wt%, and a tin tetrachloride catalyst was added. The amount of tin tetrachloride added was 1.5wt% of carboxymethyl cellulose mass, heated to 80°C in a water bath, stirred for 3h, suction filtered, and dried to obtain cellulose-grafted calcium carbonate particles. Add a proportion of 80mL to deionized water for ultrasonic vibration dispersion to obtain a suspension, heat the ...

Embodiment 2

[0039] The pretreatment method of calcium carbonate powder comprises the following steps:

[0040] Add the silane coupling agent KH550 into deionized water and stir to dissolve to obtain a silane coupling agent solution with a mass concentration of 2%. According to the ratio of calcium carbonate to silane coupling agent mass ratio of 1:0.2, add calcium carbonate powder to the silane coupling agent solution, heated to 60°C in a water bath, kept stirring for 1 hour, filtered and separated, and the product obtained by the reaction was added to a carboxymethyl cellulose solution with a mass concentration of 3.0 wt%, and a tin tetrachloride catalyst was added. The amount of tin tetrachloride added was 1.5wt% of carboxymethyl cellulose mass, heated to 80°C in a water bath, stirred for 3h, suction filtered, and dried to obtain cellulose-grafted calcium carbonate particles. Add a proportion of 80mL to deionized water for ultrasonic vibration dispersion to obtain a suspension, heat the...

Embodiment 3

[0049] The pretreatment method of calcium carbonate powder comprises the following steps:

[0050] Add the silane coupling agent KH550 into deionized water and stir to dissolve to obtain a silane coupling agent solution with a mass concentration of 2%. According to the ratio of calcium carbonate to silane coupling agent mass ratio of 1:0.2, add calcium carbonate powder to the silane coupling agent solution, heated to 60°C in a water bath, kept stirring for 1 hour, filtered and separated, added the product obtained from the reaction to a carboxymethyl cellulose solution with a mass concentration of 5.0 wt%, added tin tetrachloride catalyst, and the amount of tin tetrachloride added 1.5wt% of carboxymethyl cellulose mass, heated to 80°C in a water bath, stirred for 3h, suction filtered, and dried to obtain cellulose-grafted calcium carbonate particles. 80mL was added to deionized water for ultrasonic vibration dispersion to obtain a suspension, and the suspension was heated to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com