A kind of photoinduced shape memory color changing polymer containing spiropyran and preparation method thereof

A photoinduced shape memory and spiropyran technology, applied in the field of functional polymer preparation, can solve the problems of limiting the application range of shape memory materials, limiting the scope of application, biological tissue damage, etc., and achieves shape recovery, good shape fixation rate, easy the effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

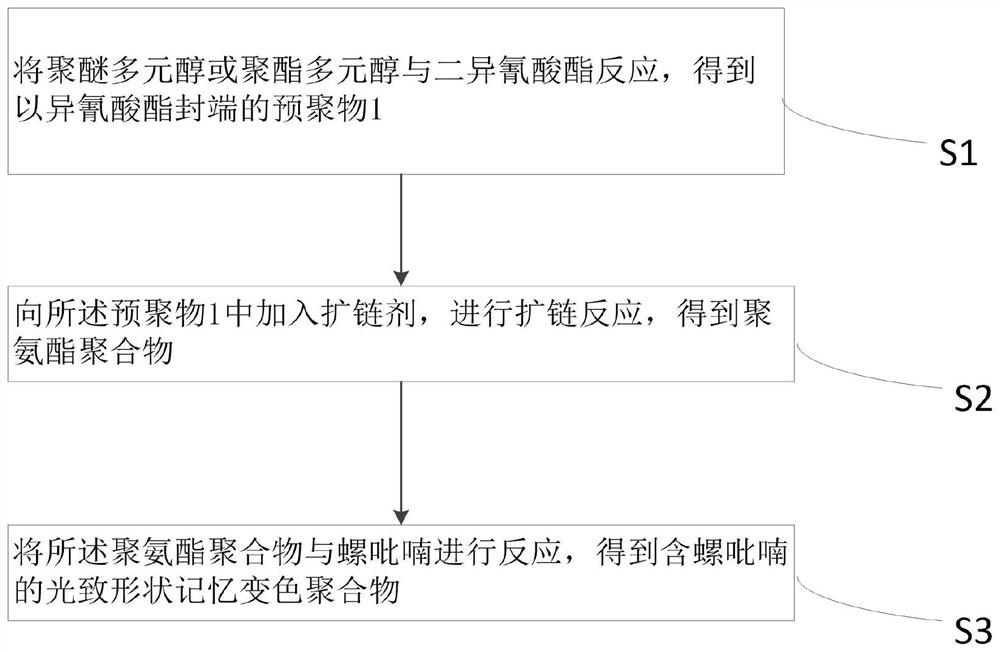

[0040] like figure 1 As shown, the embodiment of the present invention provides a preparation method of a spiropyran-containing photo-induced shape memory color-changing polymer, comprising the following steps:

[0041] Step S1, reacting polyether polyol or polyester polyol with diisocyanate to obtain prepolymer 1 terminated with isocyanate;

[0042] Step S2, adding a chain extender to the prepolymer 1, and carrying out a chain extension reaction to obtain a polyurethane polymer;

[0043] In step S3, the polyurethane polymer is reacted with the spiropyran to obtain a photo-induced shape memory color-changing polymer containing the spiropyran.

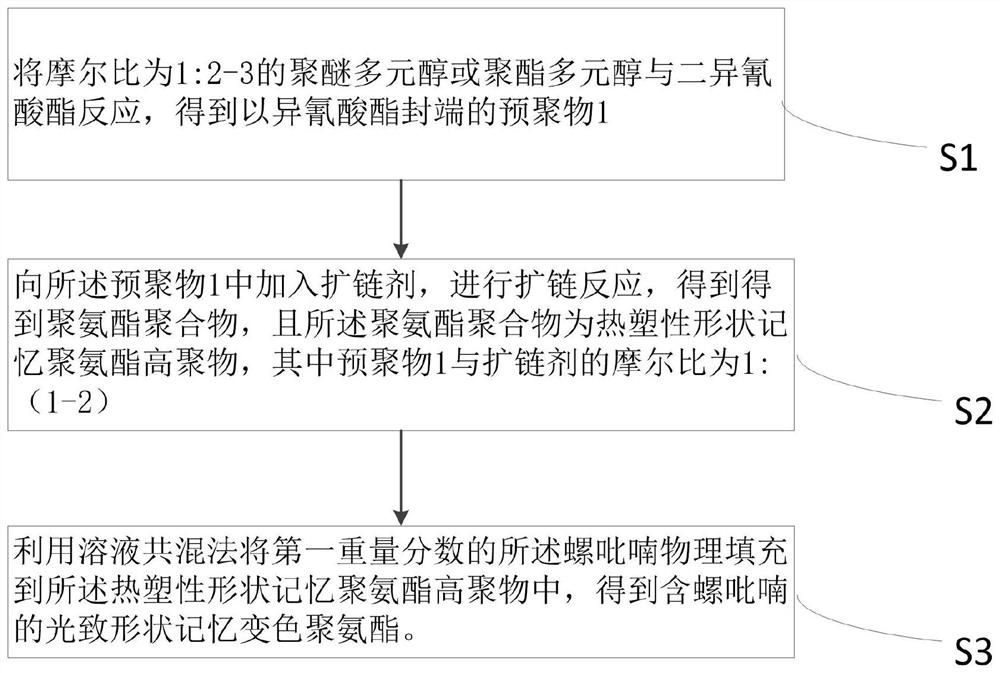

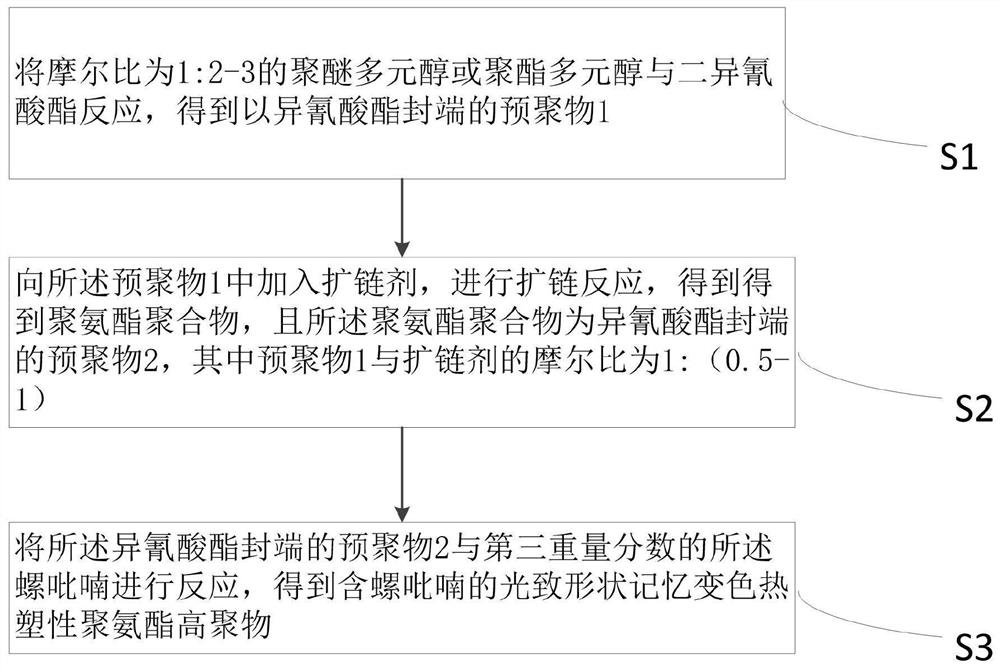

[0044] Preferably, the molar ratio of the polyether polyol or polyester polyol and diisocyanate in step S1 is 1:2-3, which can make the polyether polyol or polyester polyol and diisocyanate fully react to obtain isocyanate For the end-capped prepolymer 1, the raw materials are fully reacted to avoid waste of raw materials.

[0045] Pre...

Embodiment 1

[0070] like figure 2 and Image 6 As shown, the present embodiment provides a preparation method of a spiropyran-containing photoinduced shape memory color-changing polymer, comprising the following steps:

[0071] Step S1, add 10-30g polytetrahydrofuran ether diol (PTMEG) and 10-30g N,N-methyleneformamide (DMF) successively in the dry three-necked flask, then overlap the experimental device, and pass nitrogen and Condensed water, adjust the stirring speed to 250r / min. Slowly add 5-20g diphenylmethane-4,4,-diisocyanate (MDI) dropwise within 5min, add 5% dibutyltin dilaurate (DBTDL) after stirring for 15min, heat the oil bath to 50-80°C, continue The reaction is carried out for 1-2 h to obtain an isocyanate-terminated prepolymer 1, which is named PTMEG-MDI; wherein, the polytetrahydrofuran ether glycol (PTMEG) can be polytetrahydrofuran ether glycol (PTMEG-2000), polytetrahydrofuran ether glycol ( PTMEG-3000), polytetrahydrofuran ether glycol (PTMEG-4000) or polytetrahydrof...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is:

[0076] In step S1, diphenylmethane-4,4,-diisocyanate (MDI) can be used toluene diisocyanate (TDI), 1,6-hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI), benzene Dimethylene diisocyanate (XDI), naphthalene-1,5-diisocyanate (NDI), methylcyclohexyl diisocyanate (HTDI) or dicyclohexylmethane diisocyanate (HMDI) alternatives;

[0077] In step S2, 1,4-butanediol can be replaced with 1,6-hexanediol, diethylene glycol, neopentyl glycol, sorbitol or diethylaminoethanol;

[0078] Among them, the catalyst dibutyltin dilaurate (DBTDL) can be replaced by stannous octoate, lead octoate, cobalt octoate, iron octoate, organic bismuth or organic tin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com