Automobile cross beam and longitudinal beam connecting structure assembly

A technology for connecting structures and beams, applied in superstructure subassemblies, superstructures, connections between superstructure subassemblies, etc., can solve problems such as complex lap joint structures, low material strength steel, and failure to meet requirements, etc. Achieve the effect of fewer parts, good bending and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

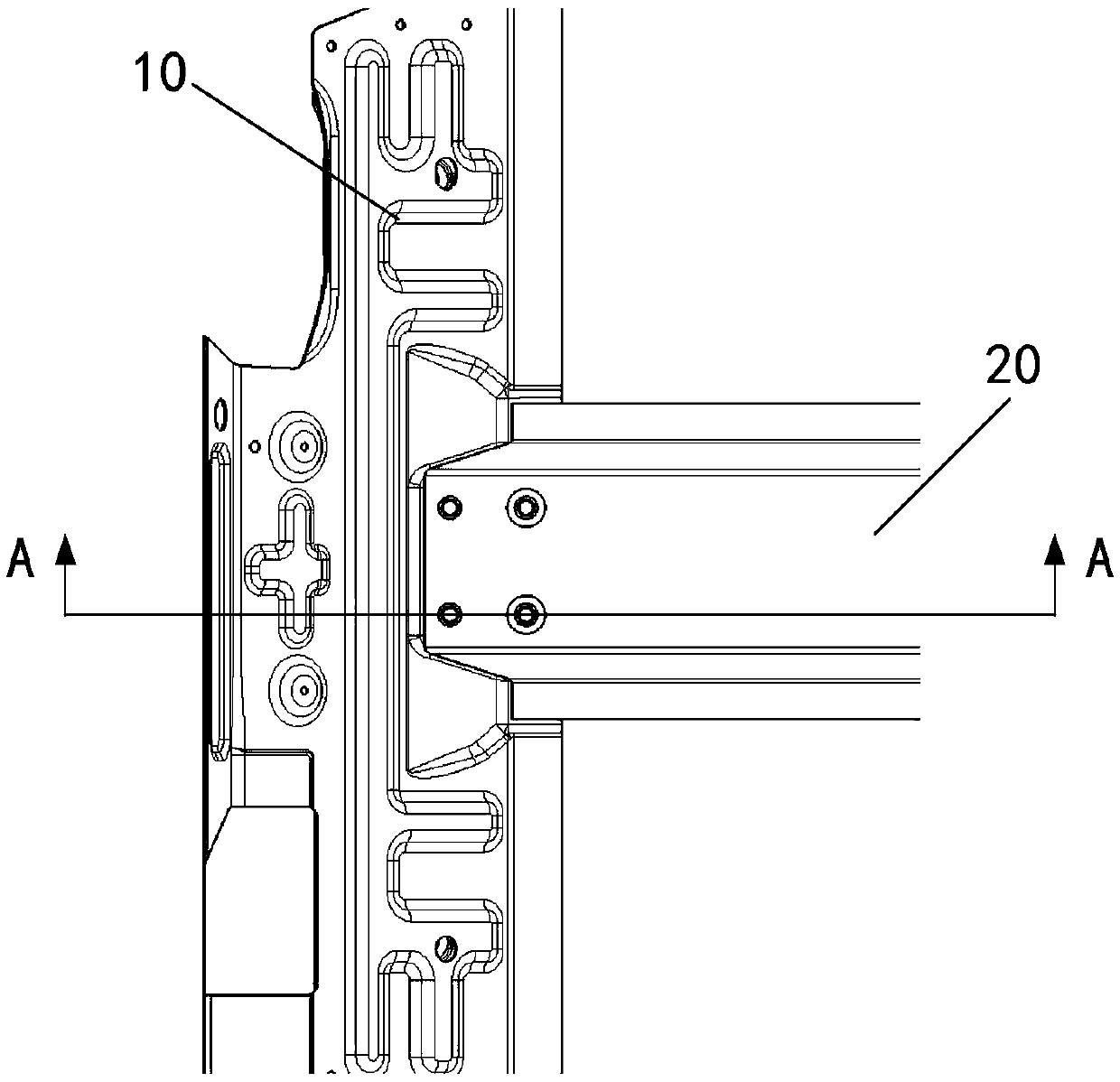

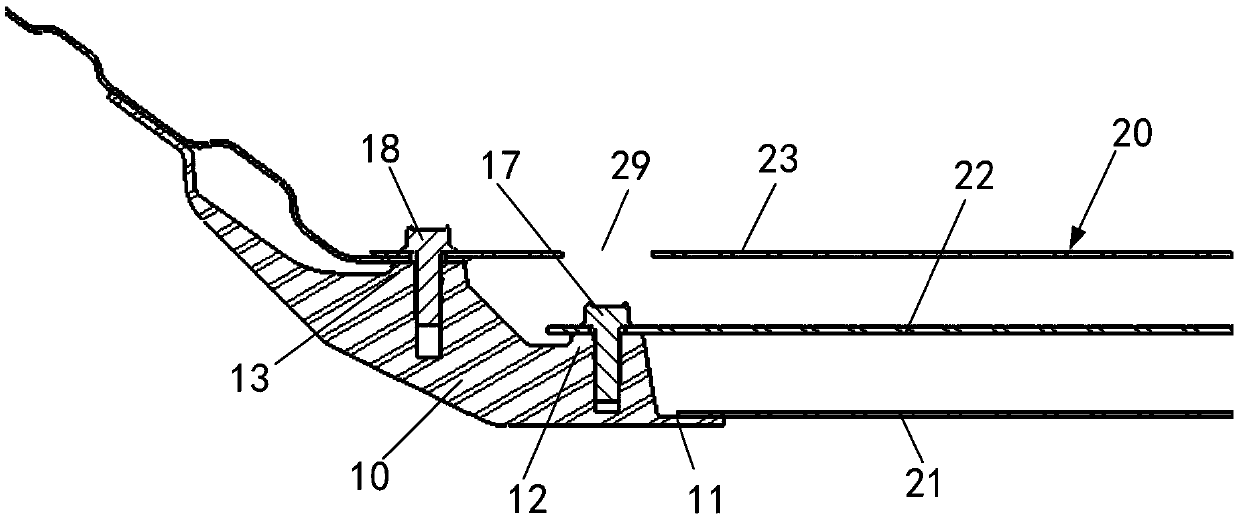

[0027] Please refer to figure 1 In one embodiment of the present invention, the connecting structure assembly between a cross beam and a longitudinal beam of an automobile includes a cross beam 10 and a longitudinal beam 20 connected to the cross beam 10 . In this embodiment, the beam 10 is a cabin beam, the longitudinal beam 20 is a middle channel, the cabin beam is a casting, and the middle channel is an aluminum alloy profile. It can be understood that the automobile beam and longitudinal beam connection structure assembly of the present invention can also be For connecting other beams and stringers.

[0028] Such as Figure 2 to Figure 4 As shown, the beam 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com