Burr removing equipment for motor barrel

A burr removal and erection technology, which is applied to metal processing equipment, parts of grinding machine tools, grinding/polishing equipment, etc., can solve problems such as increased labor costs and long burrs, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

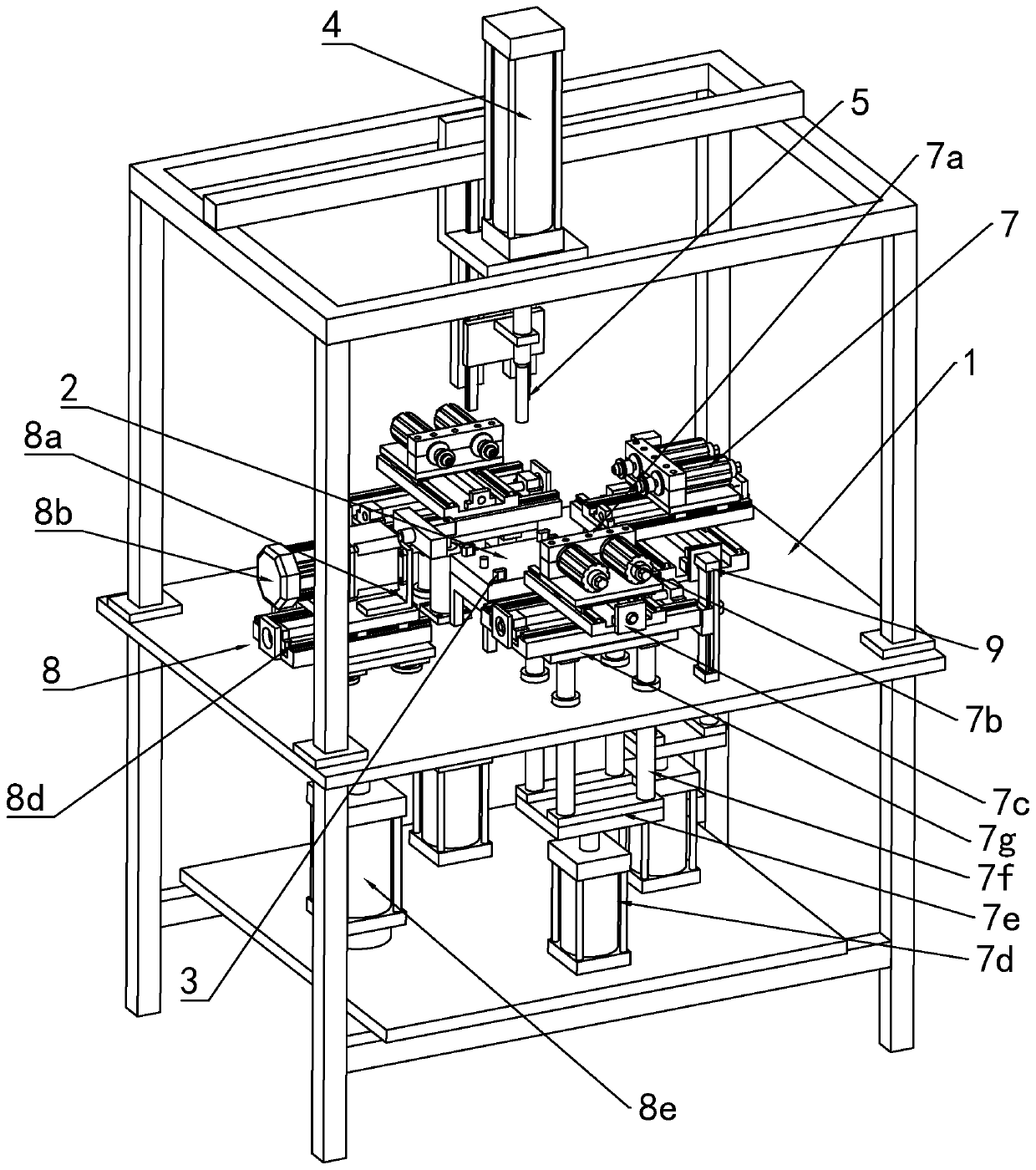

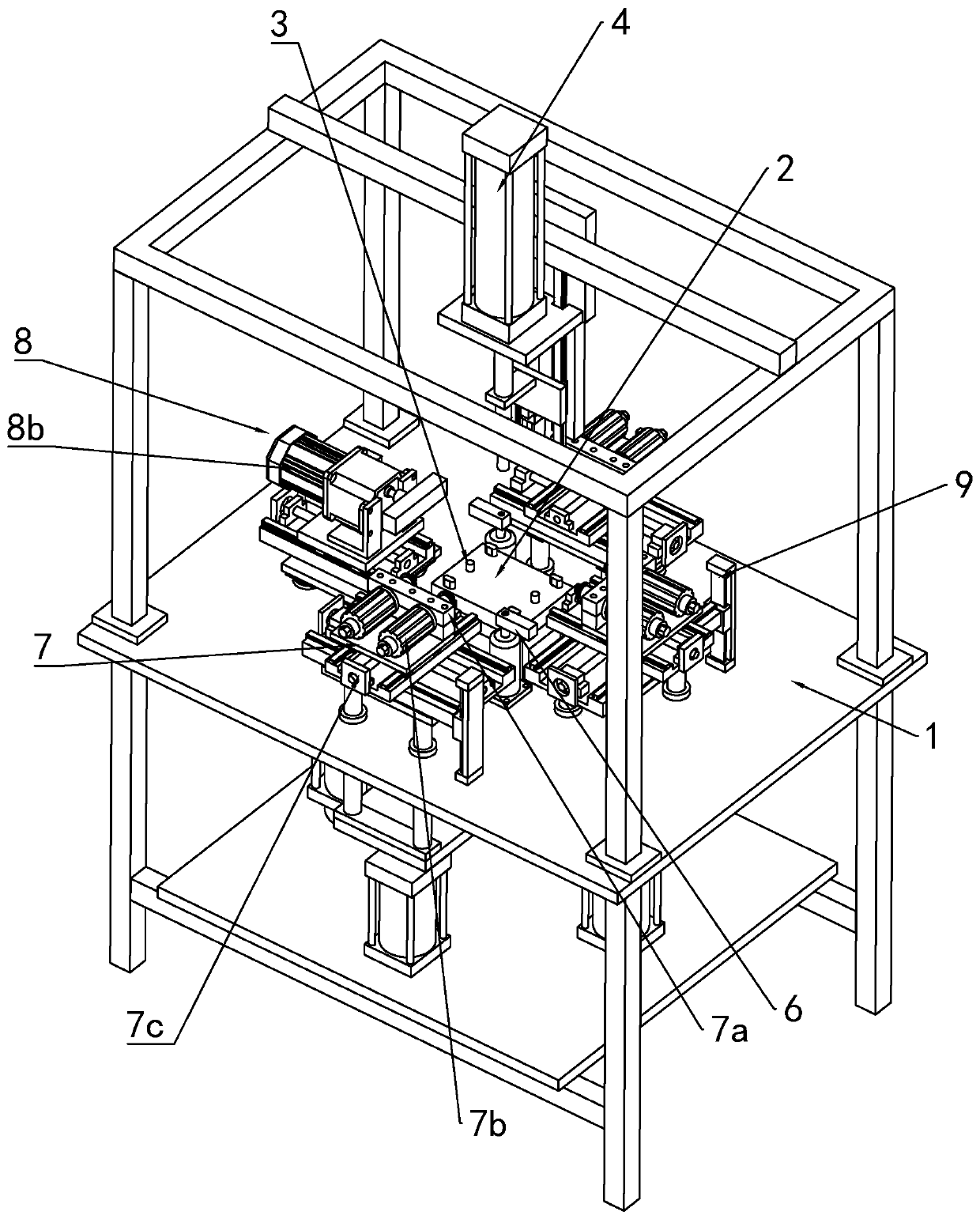

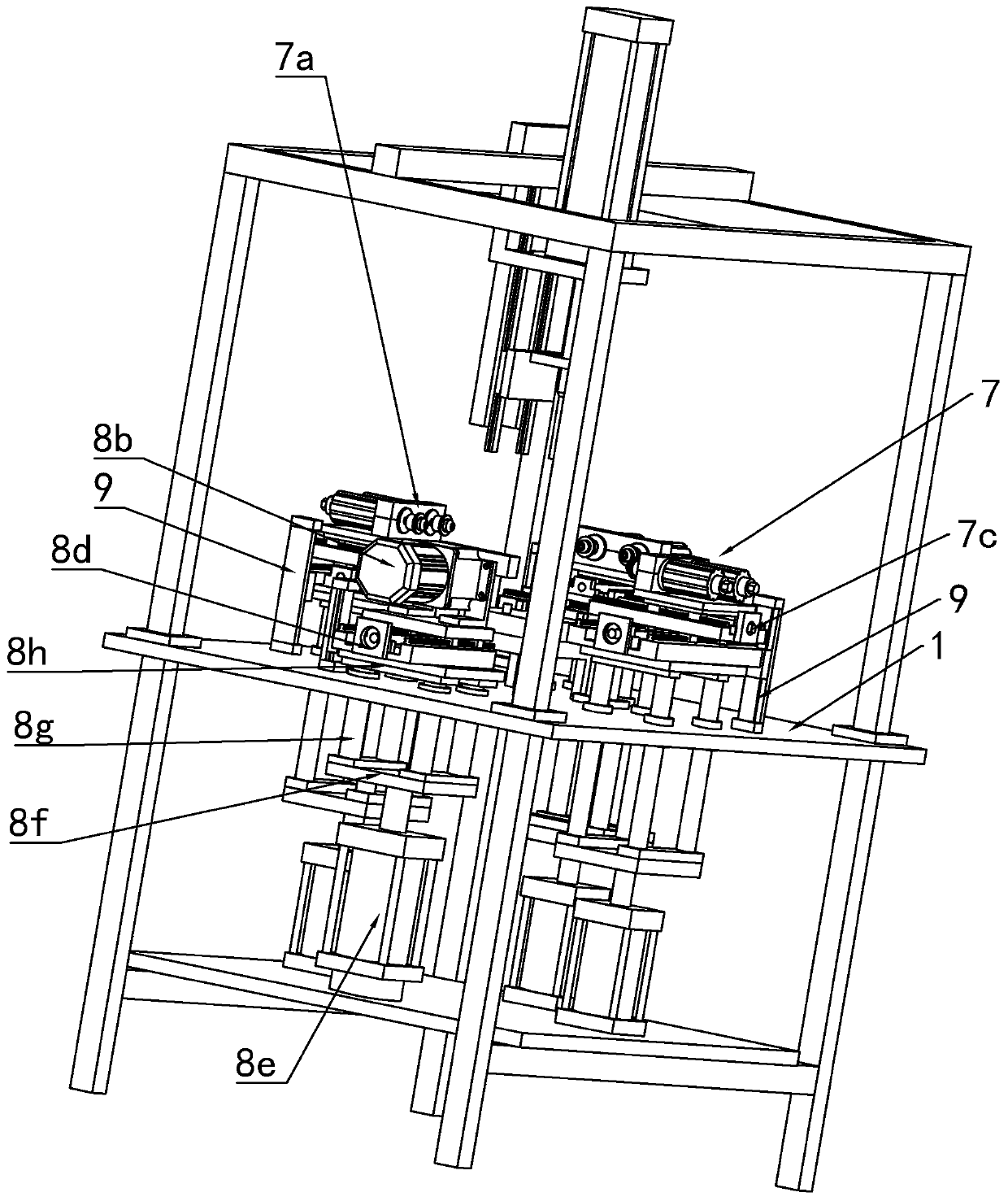

[0027] refer to Figure 1 to Figure 4 An embodiment of the present invention will be further described.

[0028] A deburring machine for a motor cylinder, comprising a support table 1, the middle part of the support table 1 is provided with a mounting seat 2 for placing a power supply machine barrel, and several columns 3 are provided at the upper end of the mounting seat 2, wherein the mounting seat 2 is detachable and replaceable; a support frame 4 is set up on the support platform 1, and a first drive cylinder with the driving end facing downward is arranged on the support frame 4 directly above the mounting seat 2, and the first drive cylinder On the driving end of the cylinder, there is a lower pressing rod 5; on both sides of the mounting seat 2, there are rotary clamping cylinders 6; Three first stations 7 and one second station 8. Wherein the cross-section of the mounting seat 2 is rectangular, and the number of rotary clamping cylinders 6 is two, which are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com