Floating dish tobacco seedling trimming device

A technology for pruning equipment and tobacco seedlings, which is applied in cutting equipment, gardening tools/equipment, botanical equipment and methods, etc., and can solve the problems of easy jamming of tobacco seedlings by cutting saw blades, low efficiency of manual pruning, uneven height of tobacco seedlings, etc. problems, to achieve the effect of easy adjustment, high work efficiency and smooth trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

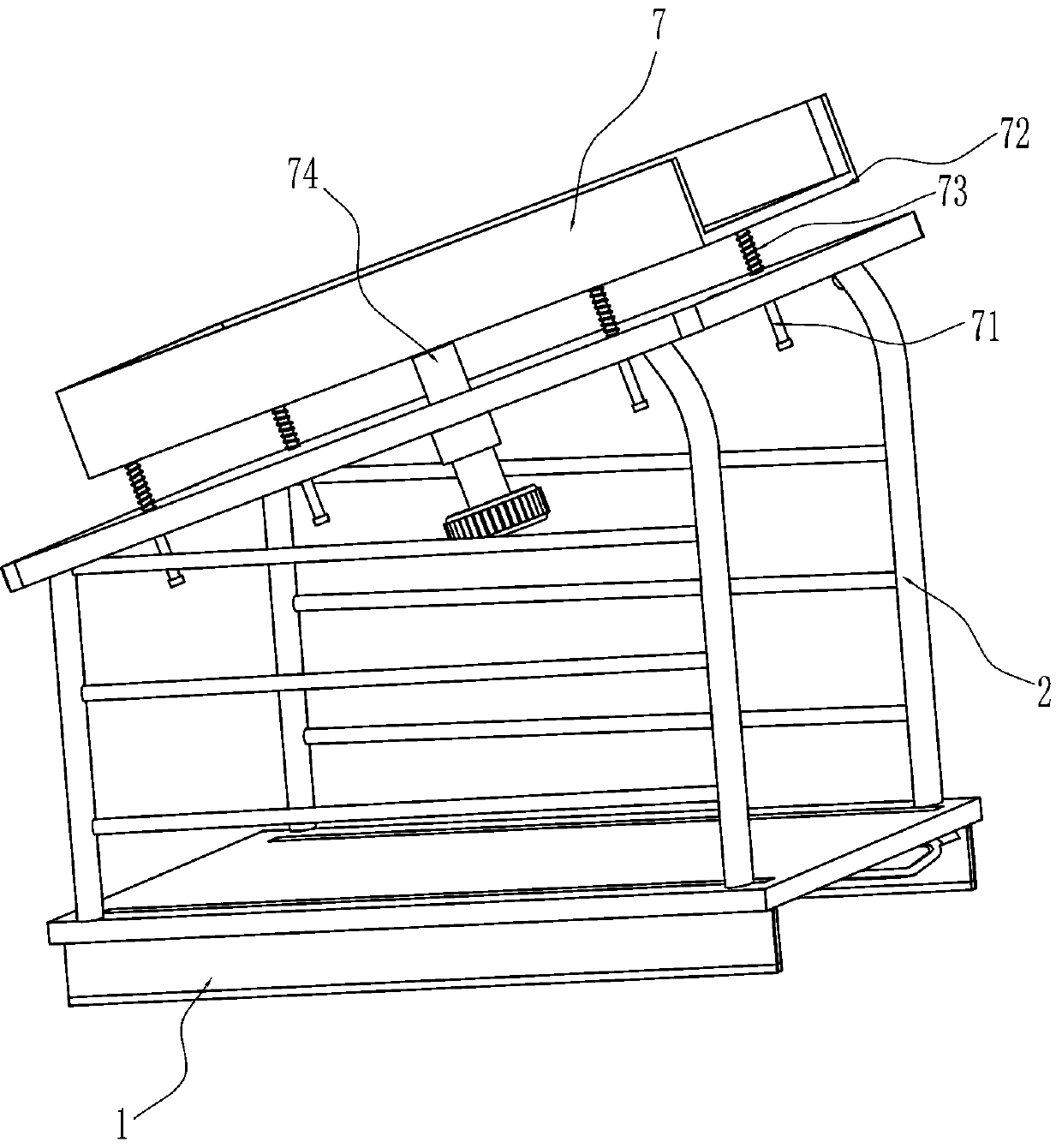

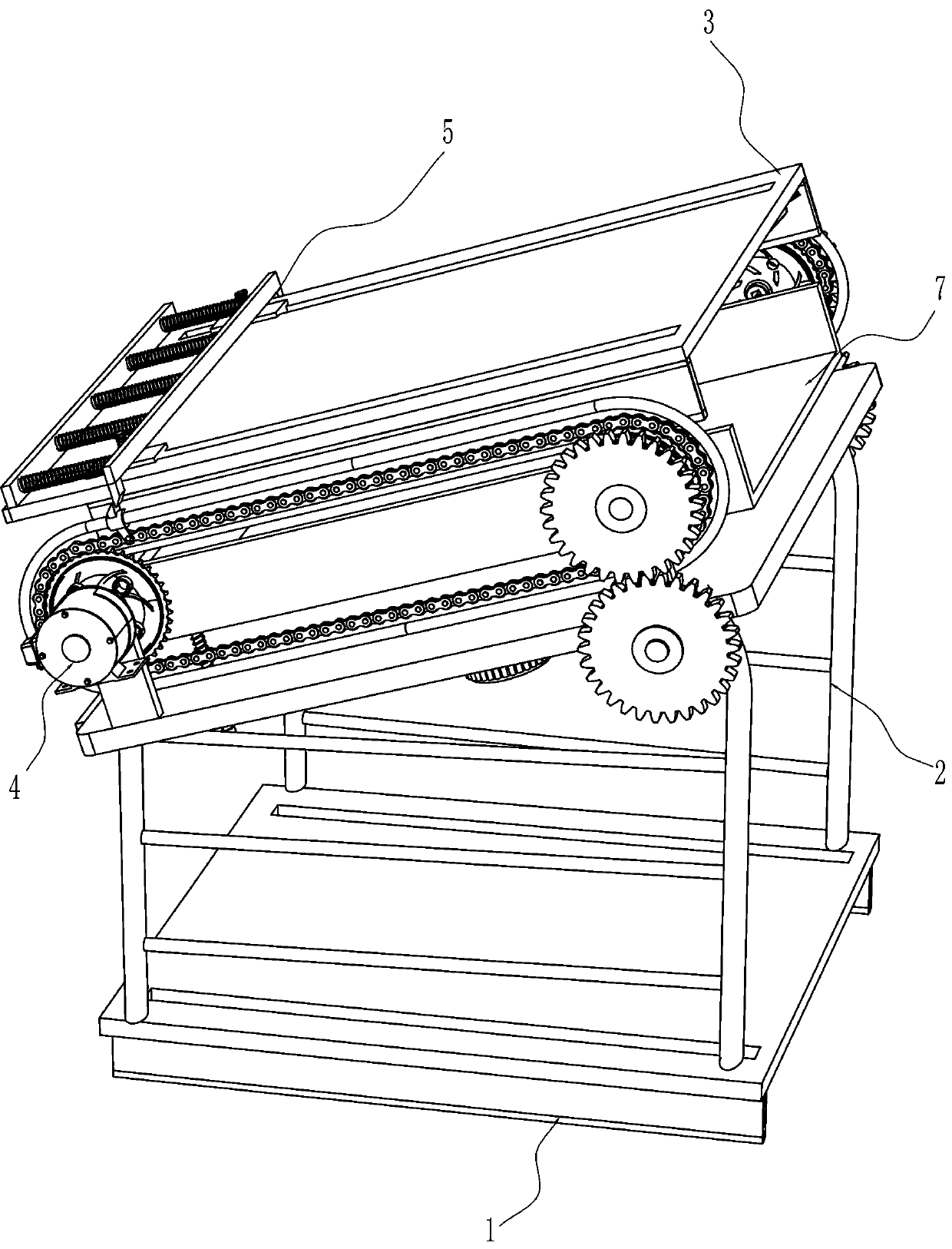

[0021] A device for pruning tobacco seedlings on floating trays, such as figure 1 , figure 2 and Figure 4 Shown, comprise base 1, frame 2, fixed plate 3, power storage mechanism 4 and pruning mechanism 5, frame 2 is installed on the top of base 1, fixed plate 3 is installed on the top of frame 2, the top of frame 2 A power storage mechanism 4 is provided between the front and rear sides, and a trimming mechanism 5 is installed on the fixed plate 3, and the power storage mechanism 4 is connected with the trimming mechanism 5 in transmission.

[0022] Power storage mechanism 4 comprises sprocket wheel 41, chain 42, reduction motor 43, annular guide rail 44, dial block 45, power transmission shaft 46, transmission gear 47 and spur gear 48, and the four corners of frame 2 top all rotate and are installed with chain. Wheel 41, wherein the front side of the left front side sprocket 41 is provided with a deceleration motor 43, the deceleration motor 43 is connected with the frame...

Embodiment 2

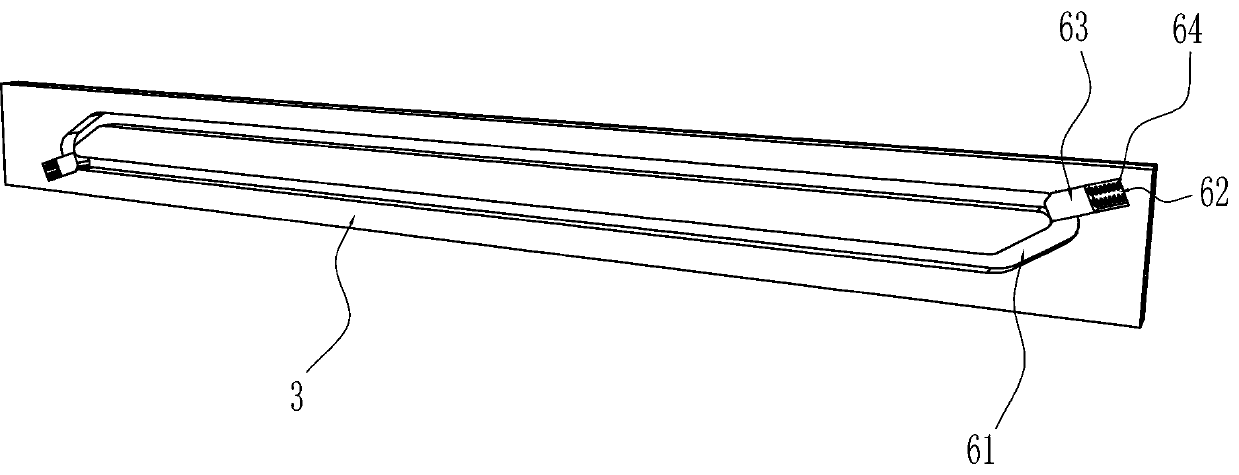

[0026] On the basis of Example 1, such as Figure 4 and 5 As shown, it also includes a guide assembly 6, the guide assembly 6 includes a one-way slider 63, a compression spring 64 and a guide rod 65, the front and rear sides of the fixed plate 3 are provided with annular grooves 61, and the left and right sides of the annular groove 61 All have chute 62 on the fixed plate 3 of chute, chute 62 is communicated with annular groove 61, and chute 62 is provided with one-way slide block 63 slidingly, and one-way slide block 63 is connected with chute 62 inner walls. A compression spring 64 is arranged, and a guide rod 65 is connected to the outer surfaces of the mounting blocks 57 on the front and rear sides, and the guide rod 65 is located in the annular groove 61 .

[0027] When the mounting block 57 and the thin steel wire rope 58 moved, the guide rod 65 rotated and moved clockwise along the annular groove 61, and when the thin steel wire rope 58 moved to the right, the guide ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com