Ionic plastic crystal-polymer-inorganic composite electrolyte membrane and preparation method and application thereof

An inorganic composite film and inorganic composite technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of difficult long-term charge and discharge cycles, poor mechanical properties, etc., achieve good cycle stability, large load capacity, and improve mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another aspect of the embodiments of the present invention provides a method for preparing an ionic plastic crystal-polymer-inorganic composite electrolyte membrane, which includes:

[0038] Mix the polymer and inorganic nanoparticles uniformly in a solvent, and prepare a porous organic-inorganic composite membrane by solution casting or phase separation;

[0039] Uniformly mixing the ionic plastic crystal compound and the lithium salt in a solvent to form an ionic plastic crystal electrolyte solution;

[0040] The porous organic-inorganic composite membrane is soaked in the ion-type plastic crystal electrolyte solution, and the solvent is removed to obtain an all-solid-state ion-type plastic crystal-polymer-inorganic composite electrolyte membrane.

[0041] In some preferred embodiments, the mass ratio of the polymer to the inorganic nanoparticles is 1:1-20:1.

[0042] Further, the polymer includes any one or a combination of two or more of polyvinylidene fluoride-hex...

Embodiment 1

[0069] Dissolve 1g of PVDF and 1g of silicon dioxide in 10g of N,N-dimethylformamide, and use the phase separation method on a glass mold to obtain PVDF-SiO with a thickness of about 60 μm 2 Composite porous support membrane, immerse the composite porous support membrane in the acetone solution of dissolving 1g N-ethyl-N-methylbisfluorosulfonimide pyrrole salt and 0.02g LiFSI to absorb the ionic plastic crystal electrolyte for 0.5h, and the composite porous support membrane The support membrane was taken out on a polytetrafluoroethylene plate and the solvent was volatilized at 80°C for 12 hours under vacuum to obtain an all-solid ionic plastic crystal-polymer-inorganic composite electrolyte membrane. The mass of the ion-type plastic crystal electrolyte supported by the composite porous support membrane is 100 times that of the polymer-inorganic composite porous support membrane.

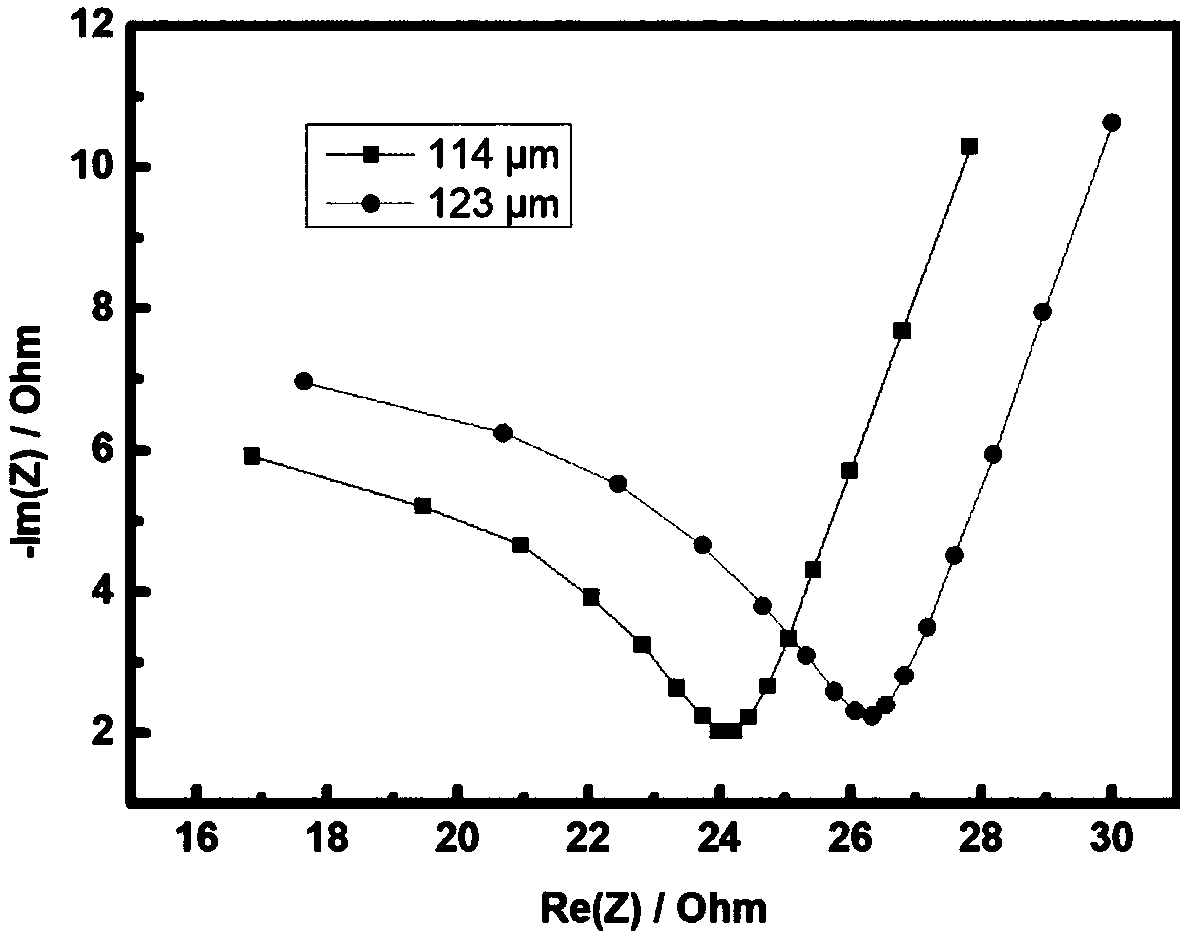

[0070] The impedance test chart of the all-solid-state ionic plastic crystal-polymer-inorganic co...

Embodiment 2

[0072]A composite plastic crystal polymer electrolyte material consists of polymer matrix PEO 1g, active nanofiller LLZTO 0.5g, lithium salt LiFSI 0.1g, ionic plastic crystal material N-ethyl-N-methyl bisfluorosulfonimide pyrrole The salt is composed of 0.6g, PEO is dissolved in 3g N,N-dimethylacetamide, and then the active nanofiller is ultrasonically dispersed in acetone, and finally the two solutions are mixed and cast on a glass plate, and the formed polymer The matrix was evaporated at 80°C for 12 hours under vacuum, and soaked in a solution mixed with 0.6g of the plastic crystal material N-ethyl-N-methylbisfluorosulfonimide pyrrole salt and 0.1g of LiFSI in the dried matrix for 24h, Continue drying at 70° C. for 25 hours under vacuum to obtain an all-solid ionic plastic crystal-polymer-inorganic composite electrolyte membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com