IGBT module solder layer fatigue aging failure simulation method based on voidage

A simulation method and technology of solder layer, which is applied in the field of fatigue aging simulation of IGBT module solder layer based on void ratio, can solve the problem of unclear influence mechanism of IGBT module reliability, inability to qualitatively and quantitatively analyze electromechanical thermal stress and reliability influence, and inability to evaluate Solder layer IGBT module reliability issues and other issues, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

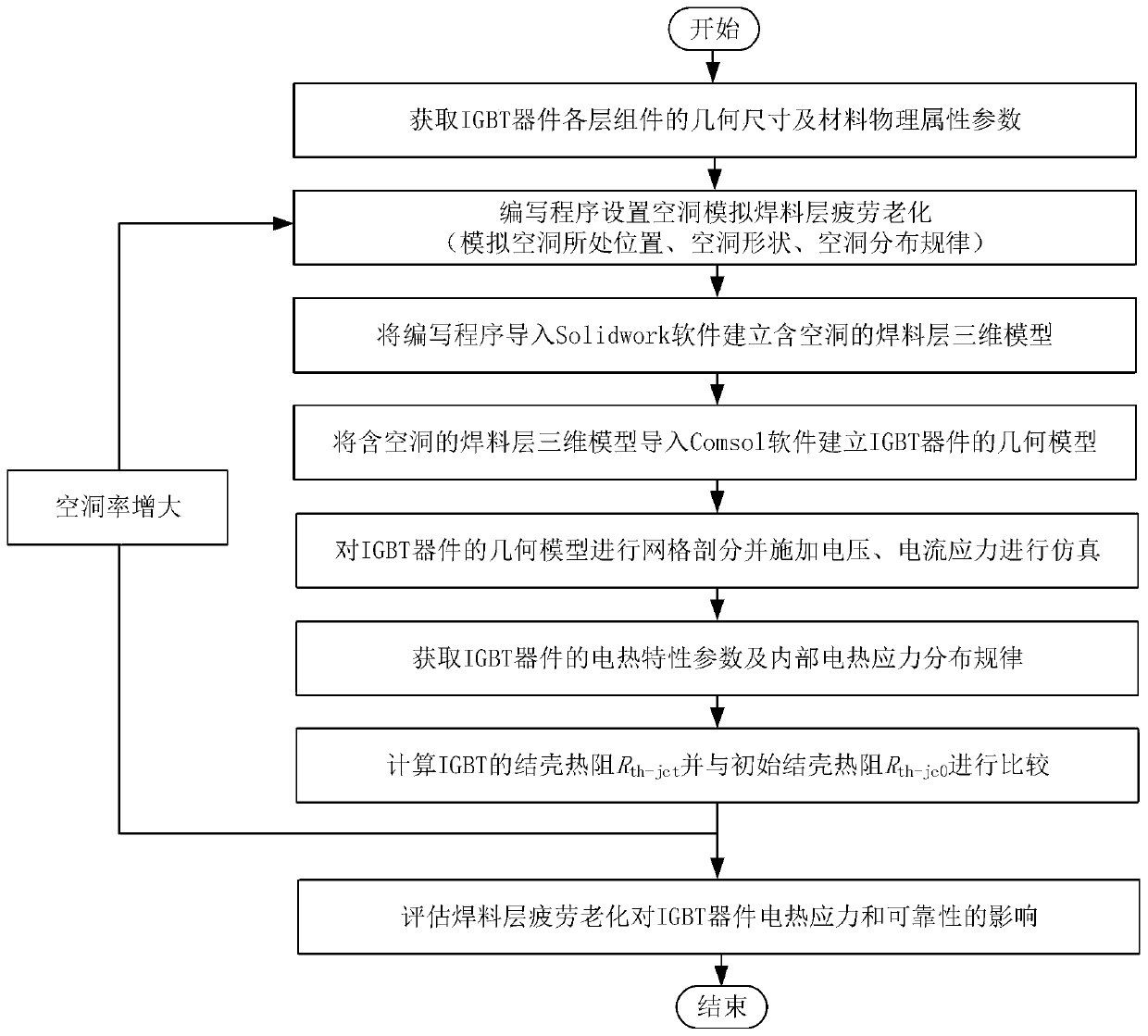

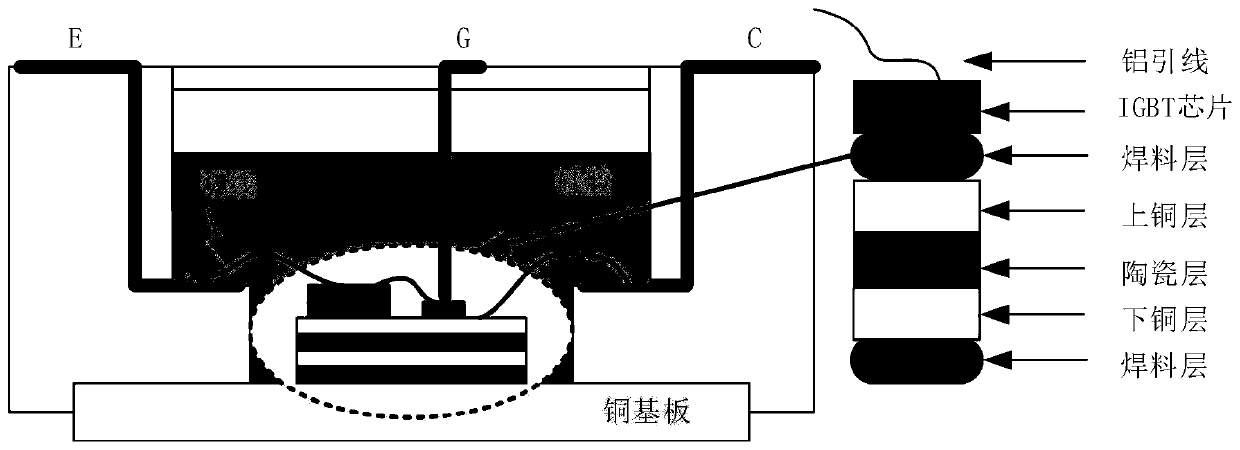

[0032] figure 1 It is a flow chart of the simulation method for the fatigue aging failure of the IGBT module solder layer, figure 2 is a schematic diagram of the cross-sectional structure of the IGBT module, image 3 It is a schematic diagram of the simulation that the voids are concentrated in different regions of the solder layer, Figure 4 It is a schematic diagram of the simulation under different fatigue aging failure states of the solder layer. in:

[0033] 1. a simulation method of fatigue aging failure of IGBT module solder layer, it is characterized in that comprising the following steps:

[0034] 1) Obtain the geometric dimensions of the components of each layer of the IGBT module and the physical property parameters of the materials of each layer, and write a program to set the voids to simulate the fatigue aging failure process of the solder layer (set the voids at different positions, different void shapes, void distribution areas, and void rates) , and impor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com