Water film cooling method and device for recovering trace yellow phosphorus in yellow phosphorus tail gas

A yellow phosphorus tail gas and cooling device technology, applied in chemical instruments and methods, phosphorus compounds, lighting and heating equipment, etc., can solve the problems of desulfurization process hazards, unsafety, excessive circulating water, etc., and achieve significant economic benefits and dangerous Reduction, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

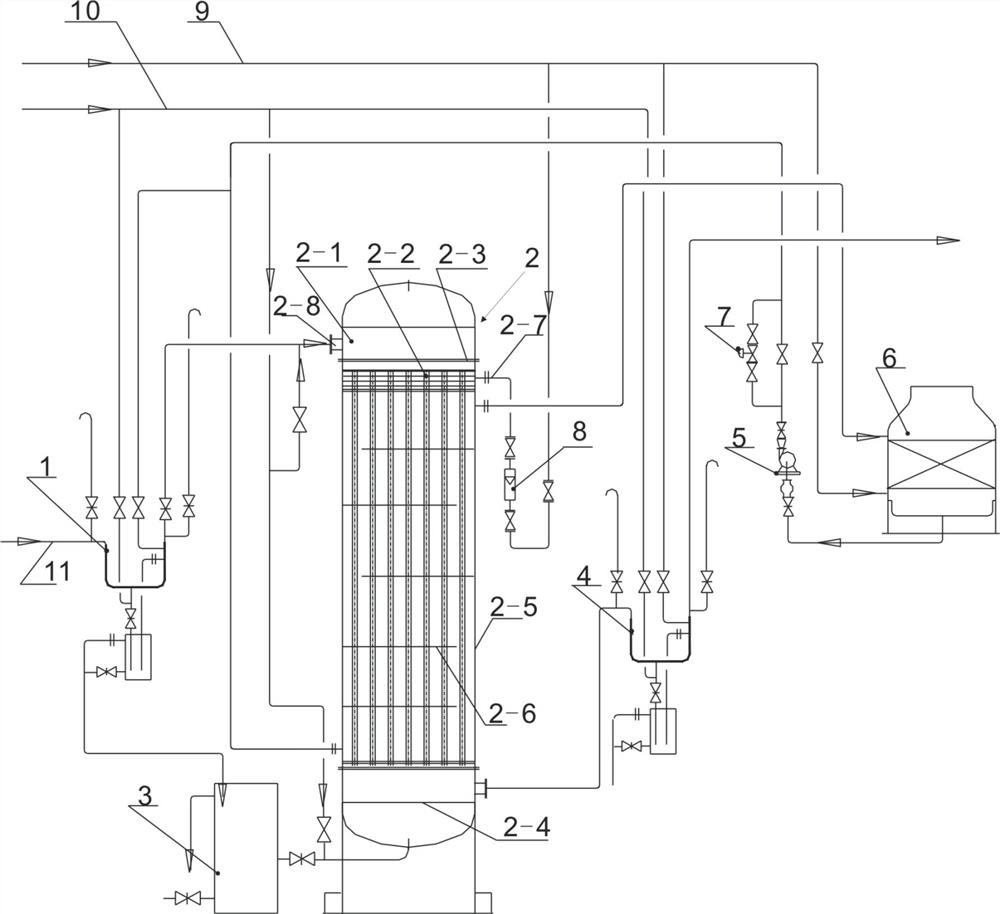

[0038] Such as figure 1 Shown: a water film cooling device for recovering trace amounts of yellow phosphorus in yellow phosphorus tail gas, which includes a process water pipe 9, a steam pipe 10, a yellow phosphorus tail gas intake pipe 11, a water film cooler 2, a yellow phosphorus storage tank 3, and a cooling water pump 5. Water cooling tower6.

[0039] The process water pipe 9 is communicated with the water film cooler 2 and the water cooling tower 6, and the inlet pipe of the water film cooler 2 is the yellow phosphorus tail gas inlet pipe 11. An inlet blocking water seal 1 is arranged on the water film cooler 2. The bottom is connected to the yellow phosphorus storage tank 3, and the outlet blocking water seal 4 is installed on the tail gas discharge pipe of the water film cooler 2. The pipeline of the water cooling tower 6 is connected to the water film cooler 2 and the inlet blocking water seal 1 after passing through the cooling water pump 5 . The steam pipeline 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com