Method for coal and gas simultaneous extraction based on one bottom pumping lane for three purposes

A technology for bottom-draining roadway and gas, which is applied in the fields of gas discharge, surface mining, mining equipment, etc., can solve the problems of difficult connection of mining, high maintenance cost of roadway, and low utilization rate of roadway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

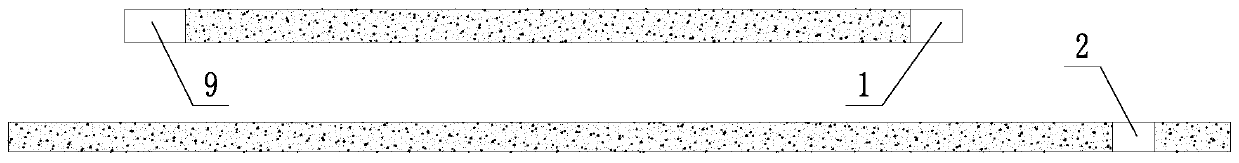

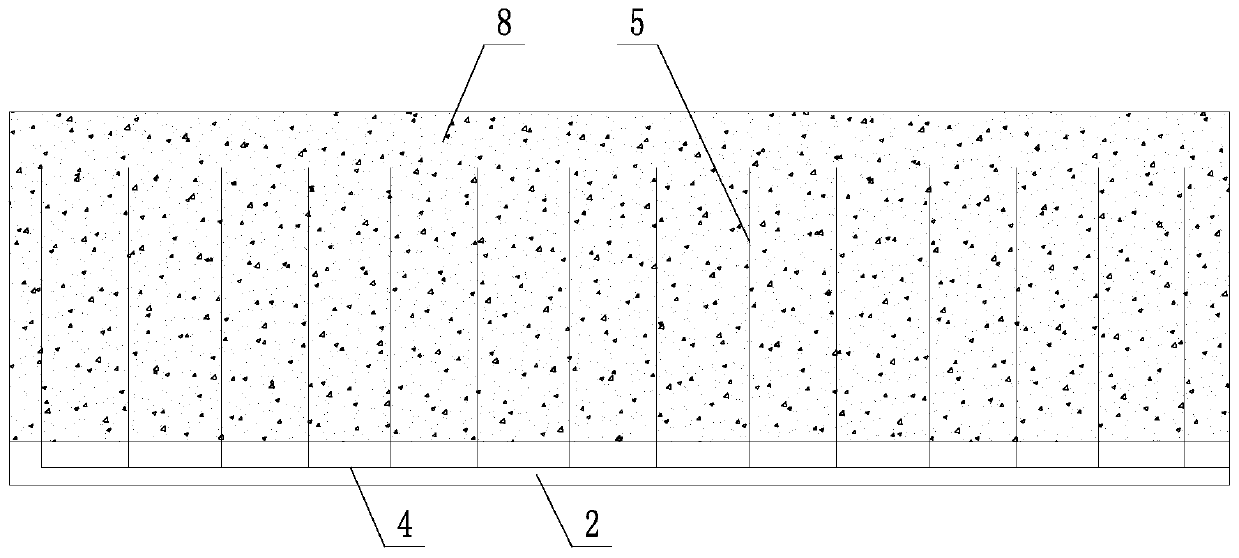

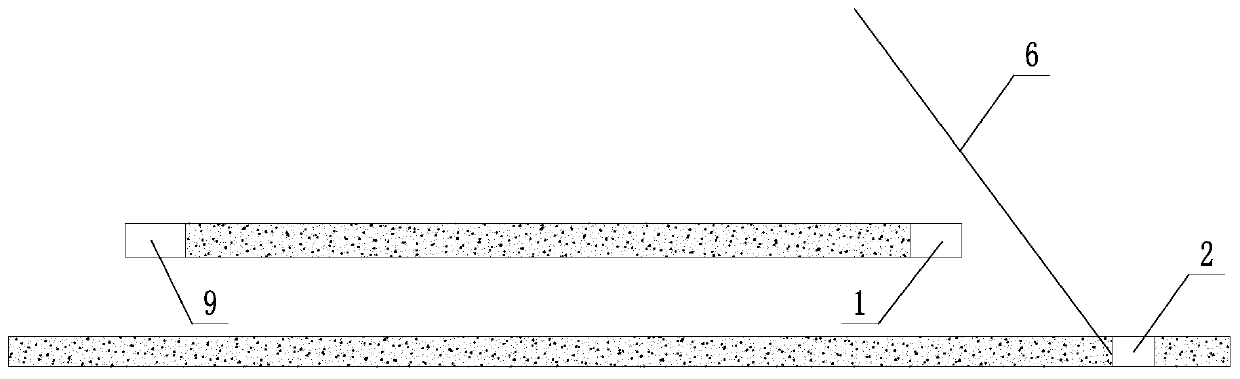

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A method for co-mining coal and gas in one alley and one alley with bottom extraction, comprising the following steps:

[0022] Step 1: According to the geological occurrence conditions of the nearby coal seam group, drill holes in the return airway 1 of the working face of the coal seam upwards adjacent to the coal seam construction roof, and downward adjacent to the coal seam construction floor, and then respectively detect the upper adjacent coal seam and the lower adjacent coal seam distance from the coal seam; at the same time, take coal samples and test and analyze the physical and mechanical parameters of each coal and rock layer; among them, the physical and mechanical parameters of each coal and rock layer that need to be tested and analyzed include lithology, compressive strength, elastic modulus, Poisson's ratio, Int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com