Drying-free multi-gun head double-channel pouring equipment for polyurethane ballast bed curing

A non-drying, polyurethane technology, applied in the field of polyurethane ballast bed, can solve the problems of low foaming operation efficiency and lower requirements for the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

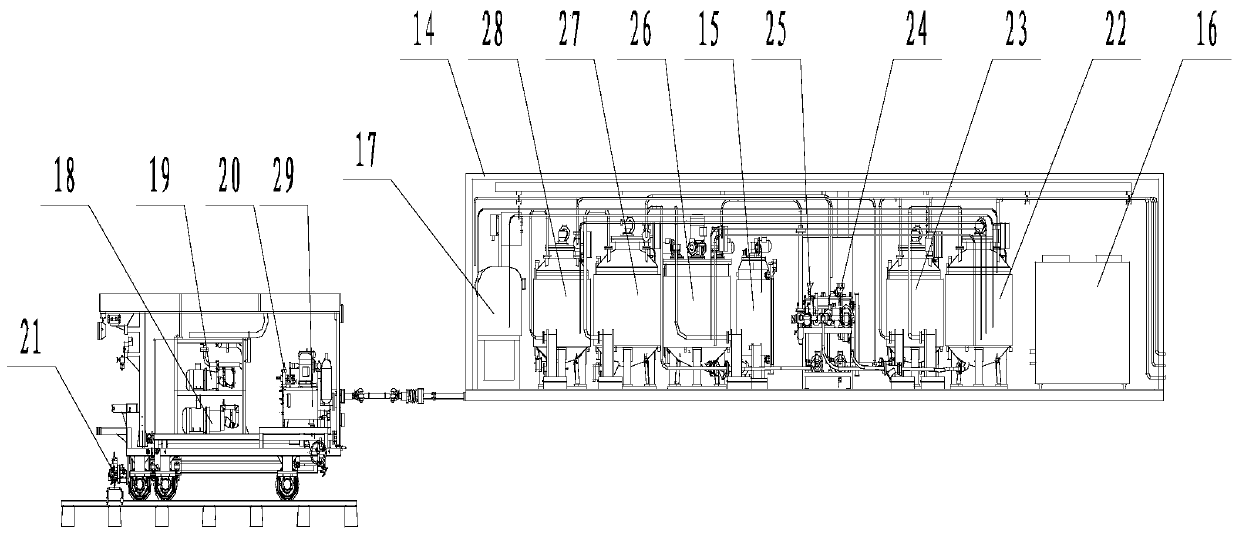

[0051] like figure 1 The shown non-drying multi-gun-head double-runner pouring equipment for polyurethane ballast bed solidification includes a container 14 and a pouring car. The container 14 includes a C component mixing tank 15 and a temperature control device for controlling the internal temperature of the container 14. Unit 16; the pouring car includes A component metering and conveying device 18, B component metering and conveying device 19, and C component metering and conveying device 20, and also includes six mixing heads 21, and the output ends of the mixing heads 21 are connected to The flow divider 5, each mixing head 21 is connected with the A component metering delivery device 18, the B component metering delivery device 19, and the C component metering delivery device 20.

[0052] Among them, component C is the premix of powdered water-absorbing agent or waterproofing agent and material B

[0053]In this embodiment, the powdery C component is added stably and s...

Embodiment 2

[0057] like Figure 1 to Figure 5 The shown non-drying multi-gun-head double-runner pouring equipment for polyurethane ballast bed solidification, on the basis of Example 1, the container 14 includes sequentially connected A component pretreatment tank 22, A component and small material pretreatment tank. Mixing device 25, component A and small material mixing tank 26, component A finished product tank 27;

[0058] The container 14 also includes a B component pretreatment tank 23 and a B component finished product tank 28 connected in sequence;

[0059] The C component mixing tank 15 is connected to the C component premixing device 24 .

[0060] A component finished product tank 27 is connected with A component metering and conveying device 18; B component finished product tank 28 is connected with B component metering and conveying device 19; C component mixing tank 15 is connected with C component metering and conveying device 20; C group The sub-metering delivery device 2...

Embodiment 3

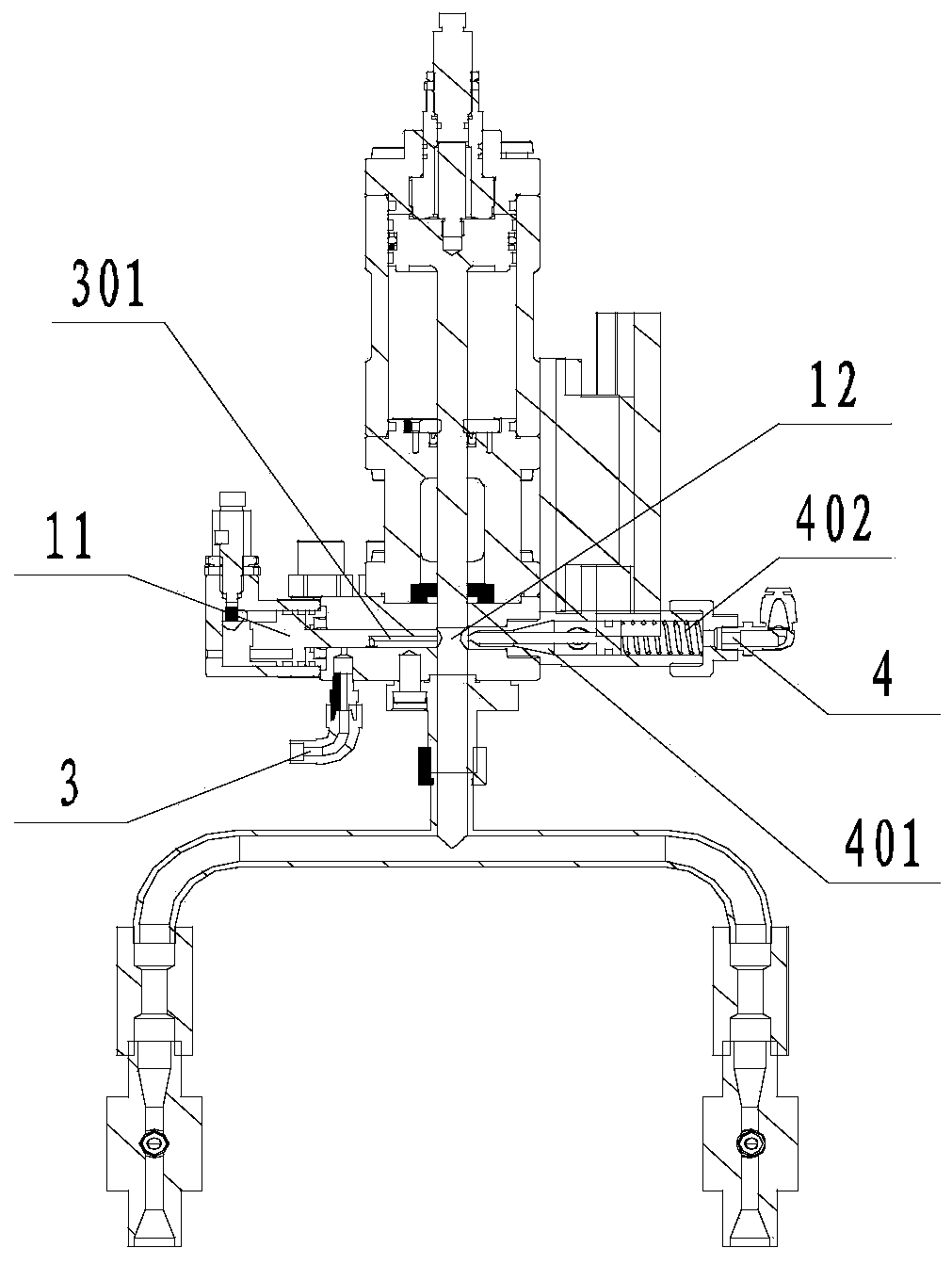

[0064] like Figure 1 to Figure 5 The shown non-drying multi-gun-head double-runner pouring equipment for polyurethane ballast bed solidification, on the basis of any of the above-mentioned embodiments, a total of six mixing heads 21 in a straight line and uniform distribution on the pouring car; the flow divider 5 includes two When working, the two forks are respectively located on both sides of a sleeper. The mixing head 21 includes a component A injection device 1 and a B component injection device 2, and a small piston 11 and a mixing chamber 12 matching the A component injection device 1 and the B component injection device 2 are arranged inside the mixing head 21, and also includes The C component injection device 3 for injecting the powder component, the C component flow channel 301 matching the C component injection device 3 is set on the small piston 11, and the C component flow channel 301 is connected to the mixing chamber 12; when the small piston 11 When it is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com