Super capacitor paper and preparation method and application thereof

A technology for supercapacitors and Tencel fibers, which is applied in the field of release paper for long-life supercapacitors, and can solve problems such as loss reduction, strength influence, and influence on supercapacitor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

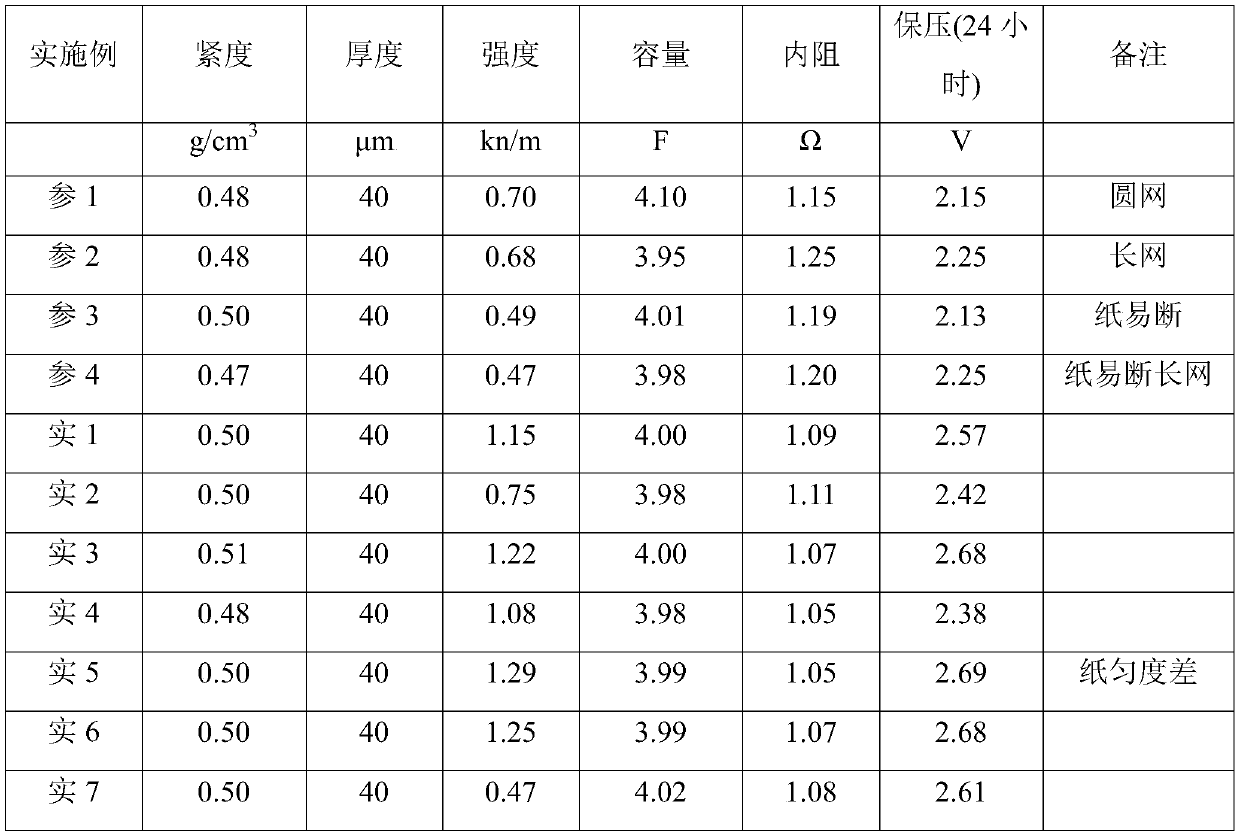

Examples

example 2

[0024] Reference example 2, tencel fiber beating degree 88 ° SR, fourdrinier paper machine papermaking, paper sheet detection quantitative, strength and other conventional indicators, made into supercapacitor test capacitance leakage current, internal resistance, capacity and other indicators.

example 3

[0025] Reference example 3, tencel fiber beating degree 88 ° SR, 0.3 denier 4mm PET fiber, weight ratio 90:10, papermaking by rotary screen paper machine, conventional indicators such as paper sheet detection quantity, strength, etc., made into supercapacitor test capacitance Leakage current, internal resistance, capacity and other indicators.

example 4

[0026] Reference example 4, tencel fiber beating degree 88°SR, 0.3 denier 3mm PET fiber, weight ratio 90:10, fourdrinier paper machine papermaking, paper sheet detection quantitative, strength and other conventional indicators, made into supercapacitor test capacitance Leakage current, internal resistance, capacity and other indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com