A mechanical stirring desulfurization method for molten iron based on bottom blowing powder

A technology of mechanical stirring and molten iron, applied in the field of desulfurization of molten iron before converter steelmaking, can solve the problems of poor entrainment and dispersion effect, unsatisfactory, loss of blade effect, etc., to prolong the entrainment cycle stroke and promote turbulent flow , Contain the effect of concentric rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of mechanical stirring desulfurization method of molten iron based on bottom blowing powder of the present embodiment, its steps are:

[0038] Step 1. Slagging off the molten iron until the exposed area of the molten iron surface reaches more than 60%, measuring the depth of the liquid surface, and measuring temperature and sampling.

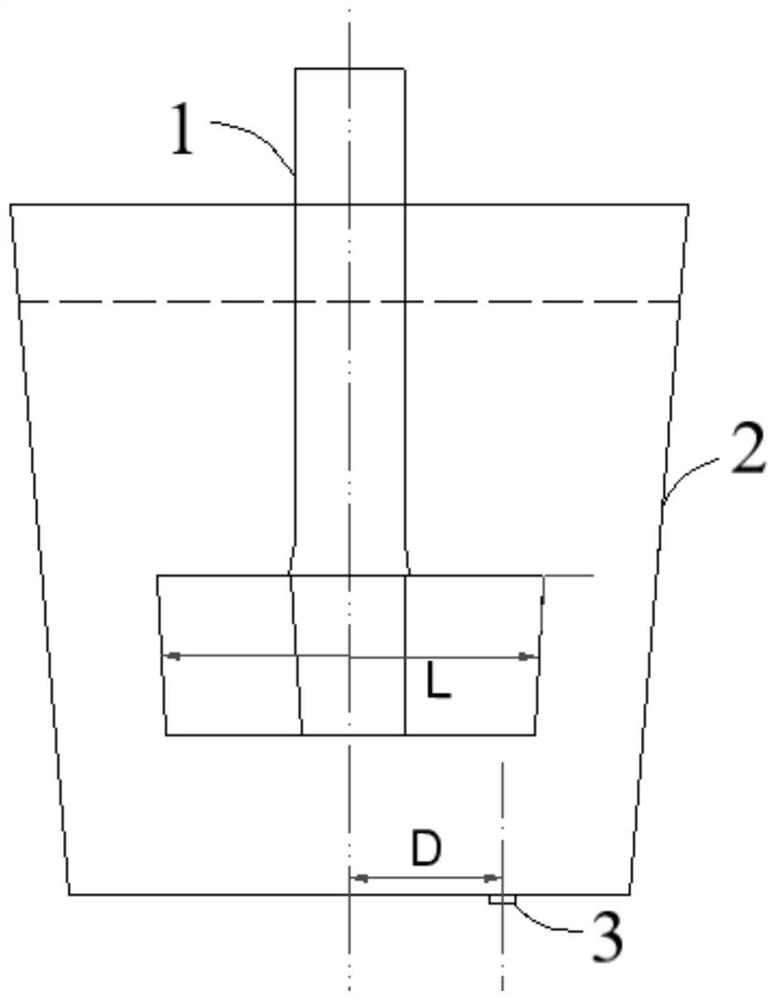

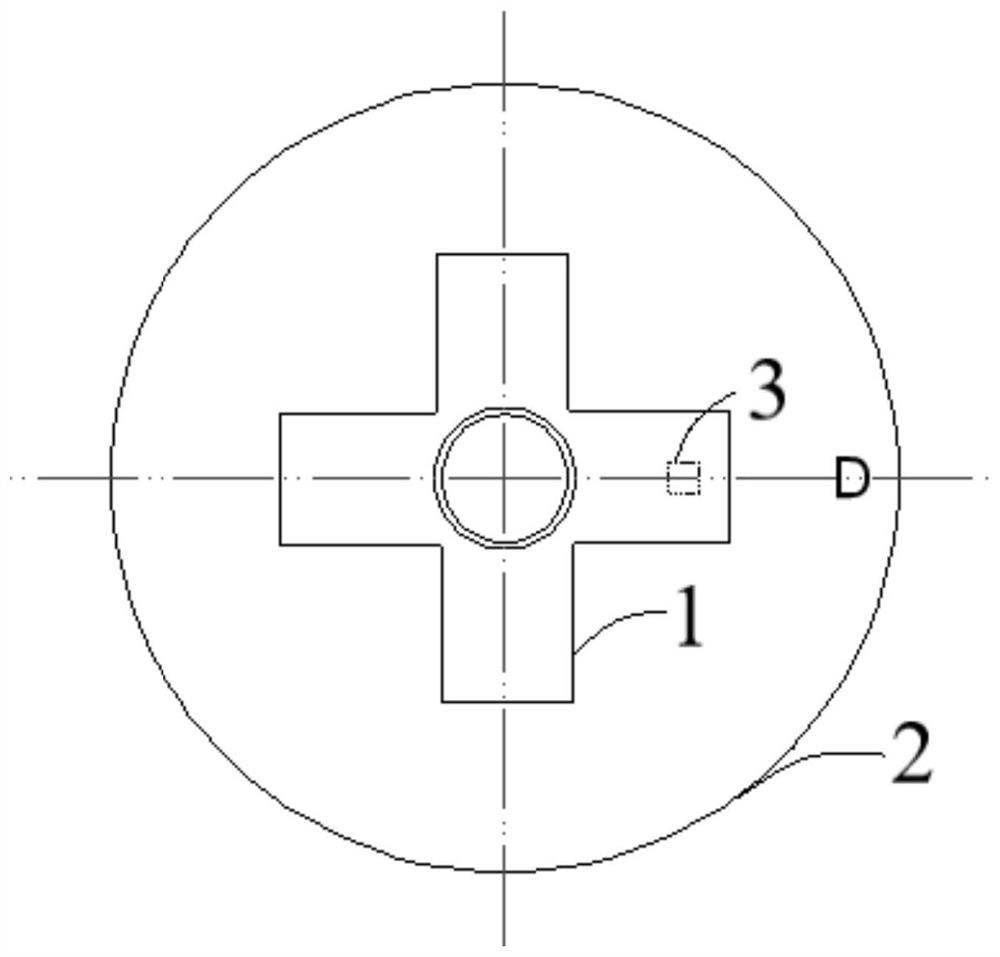

[0039] Step 2. Insert the agitator 1 into the molten iron. The insertion depth of the agitator 1 is 30% higher than that in the conventional KR method, and start to rotate. The agitator 1 is an agitator with a conventional blade structure.

[0040] Step 3. After the speed of the agitator 1 is increased to the working speed, spray the desulfurizer into the molten iron from the bottom of the molten iron tank 2:

[0041] Specifically, install a slit-type powder-spraying ventilation brick 3 at the bottom of the molten iron tank 2, and the distance between the installation position of the ventilation brick 3 and the center of the bott...

Embodiment 2

[0050] A kind of mechanical stirring desulfurization method of molten iron based on bottom blowing powder of the present embodiment, its steps are:

[0051] Step 1. Remove slag from the molten iron until the exposed area of the liquid surface of the molten iron reaches more than 60%, measure the depth of the liquid surface, and perform temperature measurement and sampling;

[0052] Step 2. Insert the agitator 1 into the molten iron. The insertion depth of the agitator 1 is 10% higher than that in the conventional KR method, and start to rotate, wherein the agitator 1 is an agitator with a conventional blade structure;

[0053] Step 3: After the rotating speed is increased to the working speed, the desulfurizer is sprayed into the molten iron from the bottom of the molten iron tank 2; wherein, the breathable brick 3 is installed at the center of the tank bottom, and the mass percentage components of the desulfurizer are: CaO: 58%, Al 2 o 3 : 14%, SiO 2 : 4%, MgO: 10%, CaF ...

Embodiment 3

[0057] A kind of mechanical stirring desulfurization method of molten iron based on bottom blowing powder of the present embodiment, its steps are:

[0058] Step 1. Remove slag from the molten iron until the exposed area of the liquid surface of the molten iron reaches more than 60%, measure the depth of the liquid surface, and perform temperature measurement and sampling;

[0059] Step 2. Insert the agitator 1 into the molten iron. The insertion depth of the agitator 1 is 20% higher than that in the conventional KR method, and start to rotate, wherein the agitator 1 is an agitator with a conventional blade structure;

[0060] Step 3: After the rotating speed is increased to the working rotating speed, the desulfurizing agent is sprayed into the molten iron from the bottom of the molten iron tank 2; wherein, the breathable brick 3 is installed in the center of the tank bottom, and the mass percentage components of the desulfurizing agent are: CaO: 59%, Al 2 o 3 : 13%, SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com