Up-conversion nano luminescent material with perovskite structure as well as preparation method and application thereof

A technology of nano-luminescent material and perovskite structure, which is applied in the fields of luminescent materials, nano-optics, nano-technology, etc., can solve the problems of difficulty in obtaining small-sized particles and cannot be widely used, and achieve small particle size and regular morphology. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

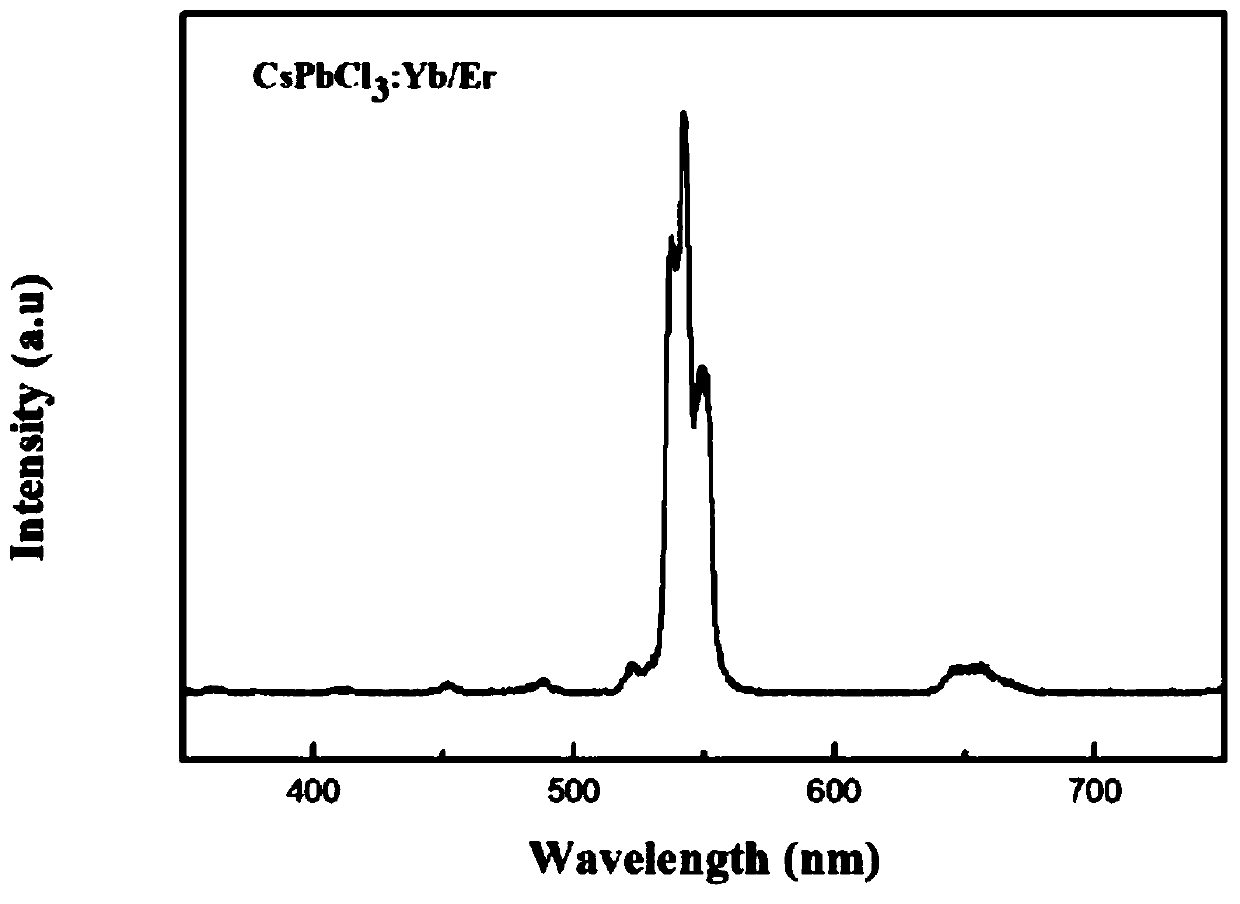

[0031]Up-conversion nano-luminescent material: CsPb 0.999625 Yb 0.0003 Er 0.000075 Br 3 quantum dots;

[0032] Weigh 0.0614gCs 2 CO 3 To a 50ml three-necked flask, add 2ml oleic acid, 8ml octadecene, in N 2 Heat to 120°C under atmosphere and keep for 1h; continue heating to 150°C and keep for 10min until Cs 2 CO 3 Completely dissolved, the light yellow clear liquid is the precursor of the prepared cesium oleate.

[0033] According to the chemical formula CsPb 0.999625 Yb 0.0003 Er 0.000075 Br 3 The stoichiometric ratio of each element in , respectively weighed 0.1163gYbCl 3· 6H 2 O, 0.0280g ErCl 3· 6H 2 O and 0.0690gPbBr 2 , into a 100ml three-necked flask; then add 5ml oleic acid, 3ml oleylamine, and 20ml octadecene into the three-necked flask; under nitrogen protection, heat the solution to 160°C for 4 hours; then continue heating to 240°C ; The cesium oleate preheated to 100 ℃ was quickly injected into the three-necked flask, and after 10s, the ice bath was...

Embodiment 2

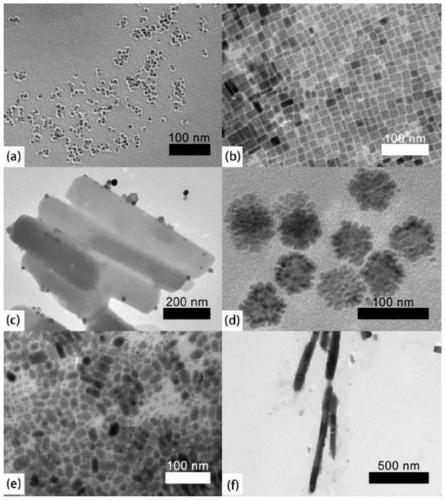

[0039] CaPb 0.999625 Yb 0.0003 Er 0.000075 Br 3 Preparation of nanocubes

[0040] Weigh 0.0614gCs 2 CO 3 To a 50ml three-necked flask, add 2ml oleic acid, 8ml octadecene, in N 2 Heat to 120°C under atmosphere and keep for 1h; continue heating to 150°C and keep for 10min until Cs 2 CO 3 Completely dissolved, the light yellow clear liquid is the precursor of the prepared cesium oleate.

[0041] According to the chemical formula CsPb 0.999625 Yb 0.0003 Er 0.000075 Br 3 The stoichiometric ratio of each element in , respectively weighed 0.1163gYbCl 3. 6H 2 O, 0.0280g ErCl 3. 6H 2 O and 0.0690gPbBr 2 , into a 100ml three-necked flask; then add 5ml oleic acid, 3ml oleylamine, and 20ml octadecene into the three-necked flask; under nitrogen protection, heat the solution to 95°C and keep it for 2h; then continue heating to 120°C , maintained for 10 minutes, cooled to 55°C, quickly injected cesium oleate preheated to 100°C into the three-necked flask, and cooled to room ...

Embodiment 3

[0045] CaPb 0.9997195 Yb 0.0002244 Er 0.0000561 Br 3 Preparation of nanoribbons

[0046] Weigh 0.0614gCs 2 CO 3 To a 50ml three-necked flask, add 2ml oleic acid, 8ml octadecene, in N 2 Heat to 120°C under atmosphere and keep for 1h; continue heating to 150°C and keep for 10min until Cs 2 CO 3 Completely dissolved, the light yellow clear liquid is the precursor of the prepared cesium oleate.

[0047] According to the chemical formula CsPb 0.9997195 Yb 0.0002244 Er 0.0000561 Br 3 The stoichiometric ratio of each element, respectively weighed 0.0869g YbCl 3. 6H 2 O, 0.0214g ErCl 3. 6H 2 O and 0.0690gPbBr 2 , into a 100ml three-necked flask; then add 5ml oleic acid, 3ml oleylamine, and 20ml octadecene into the three-necked flask; under nitrogen protection, heat the solution to 180°C and keep it for 6h; then continue heating to 260°C ; The cesium oleate preheated to 100 ℃ was quickly injected into the three-necked flask, and after 10s, the ice bath was cooled to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com