Double-roller linkage winding type lifting system

A lifting system and winding technology, which is applied in the field of double-drum linkage winding lifting system, can solve the problems of small payload, low energy efficiency ratio, low energy efficiency ratio of the lifting system, etc., and achieve the effect of improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

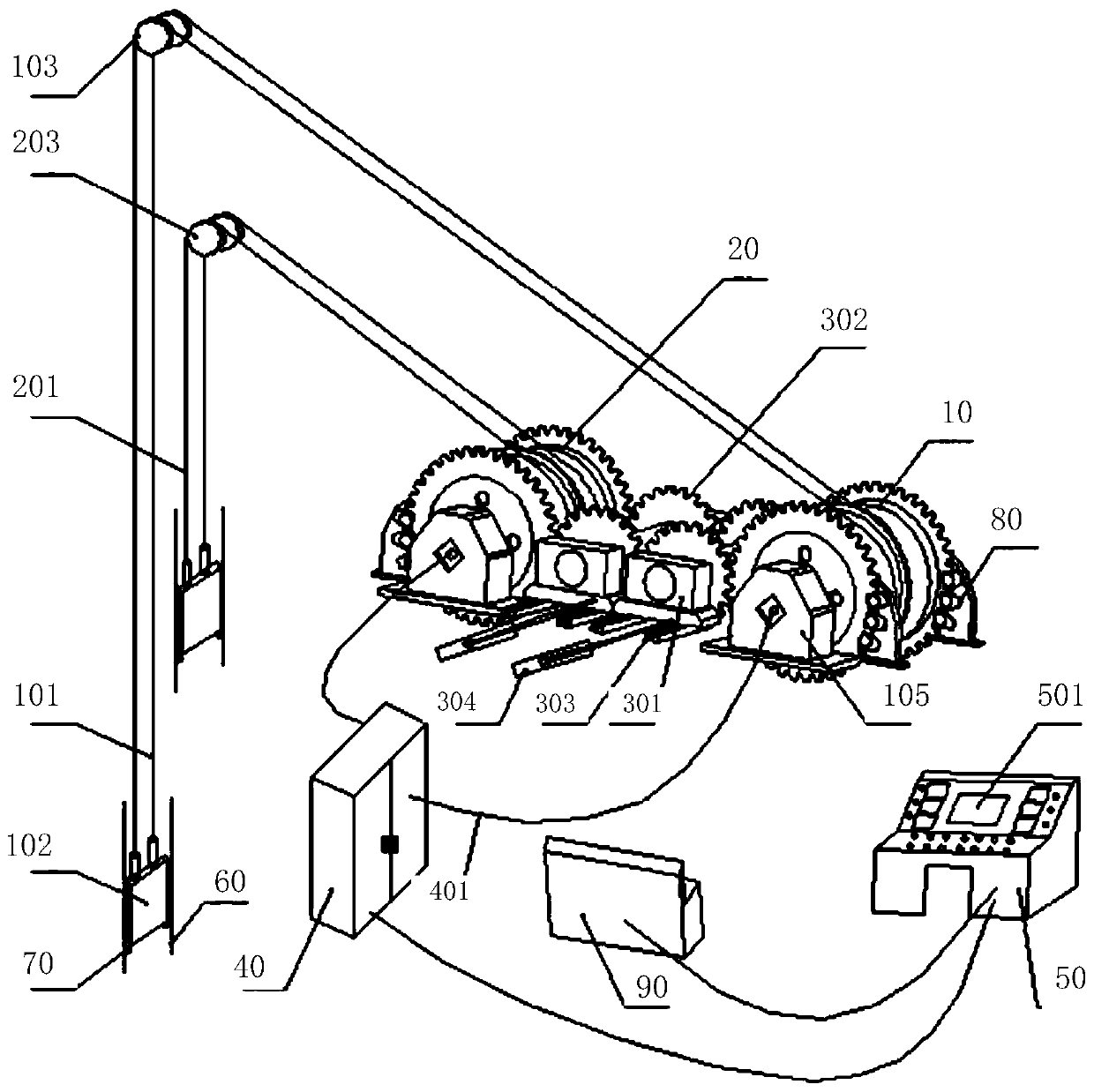

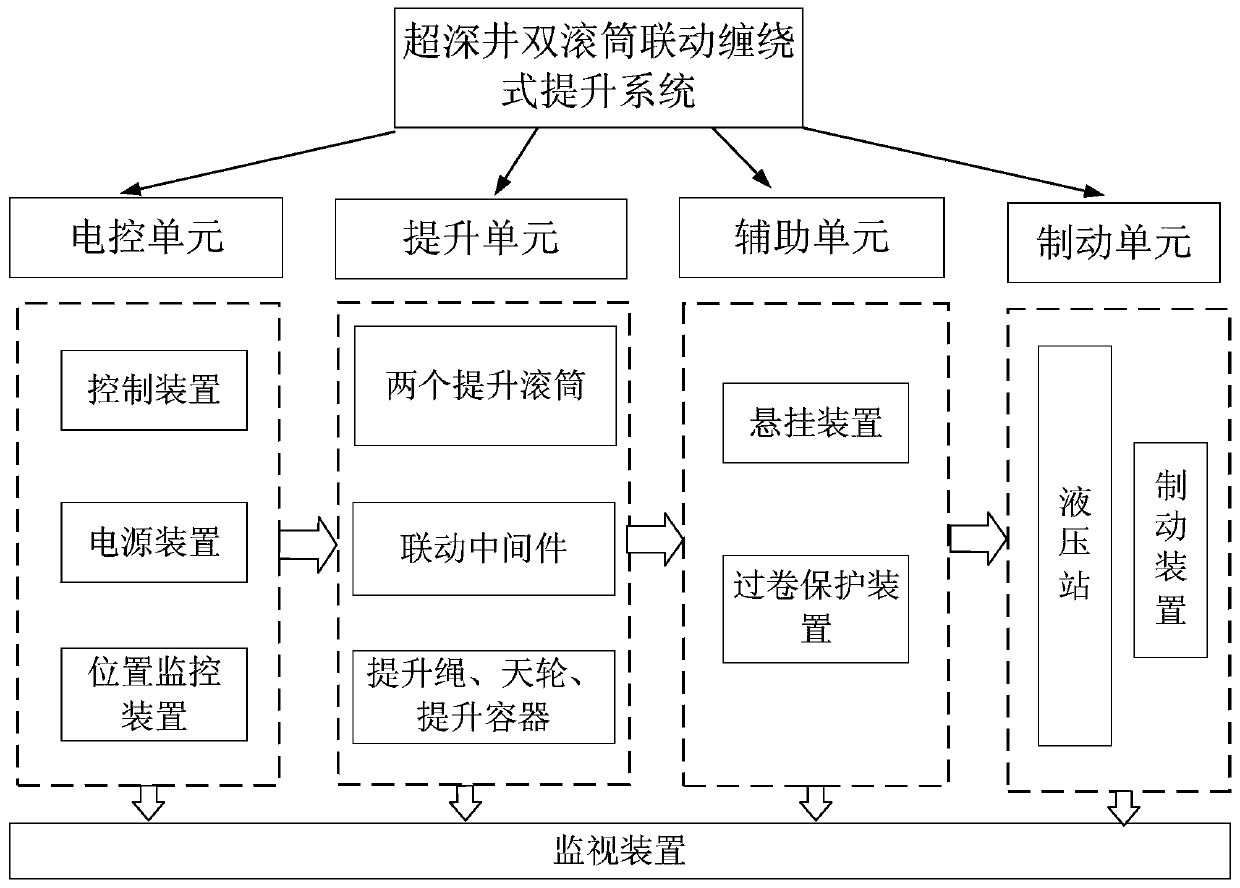

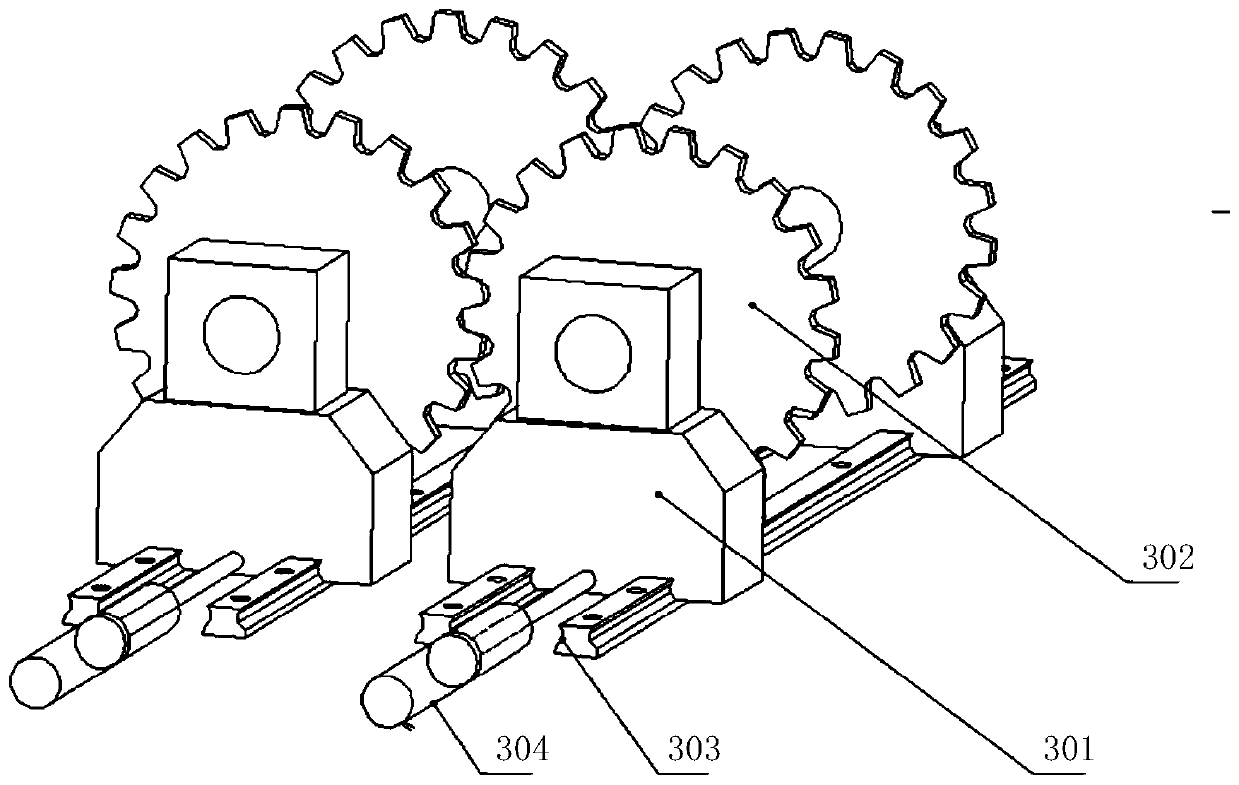

[0022] An embodiment of the present invention provides a double-roller linkage winding lifting system, the system includes a first lifting roller and a second lifting roller, and the first lifting roller and the second lifting roller are engaged through an engagement structure on the outer circumference Linkage or linkage through a linkage intermediate piece; the first hoisting drum is wound with a first hoisting rope, the second hoisting drum is wound with a second hoisting rope, and the first hoisting rope and the second hoisting rope are not connected to each other.

[0023] The lifting roller here is a winding roller; linkage refers to the linkage of rotation, that is, one lifting roller rotates, and the other lifting roller rotates synchronously. For the sake of brevity, the first lifting roller and the second lifting roller are collectively referred to as lifting rollers.

[0024] The double-drum linkage winding lifting system of the embodiment of the present invention l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com