A pr shake suppression method based on stagnation point calibration

A stagnant point and frequency technology, applied in the field of PR shake suppression based on stagnation point calibration, can solve problems such as easy occurrence of jitter and inability to effectively suppress jitter, so as to ensure timeliness and real-time performance, expand the range of rotating speeds, and avoid signal delays. effect when

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

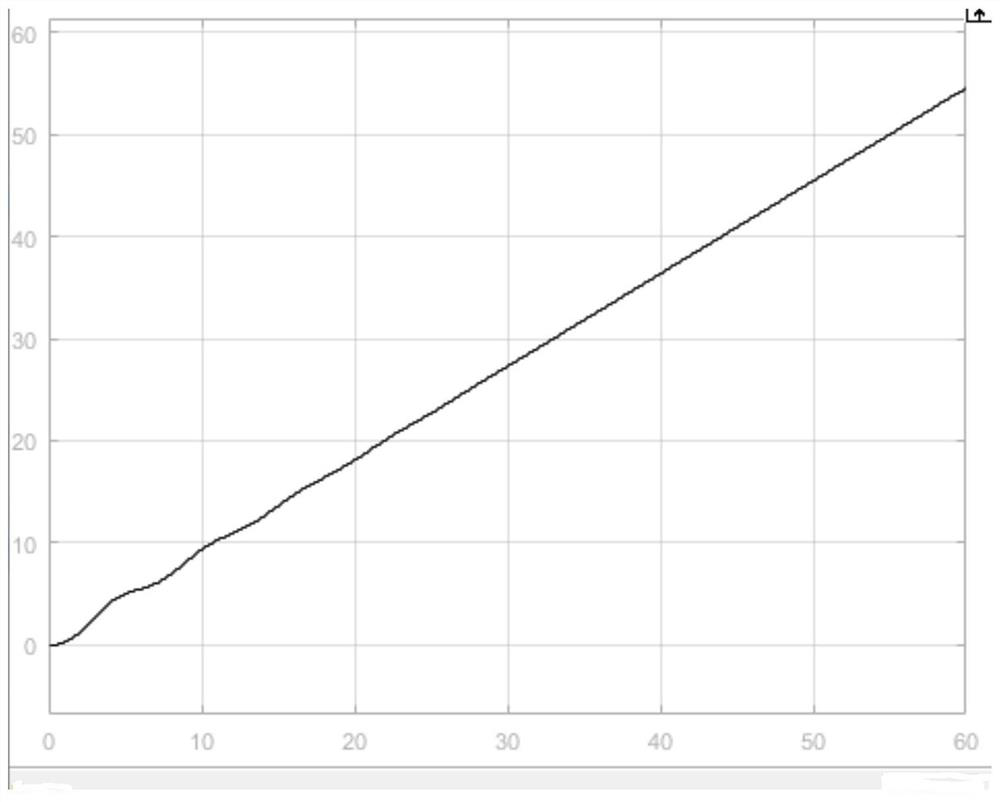

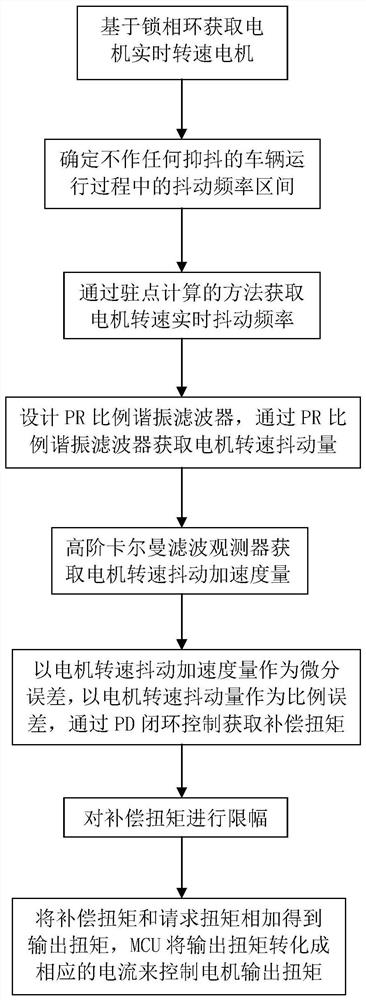

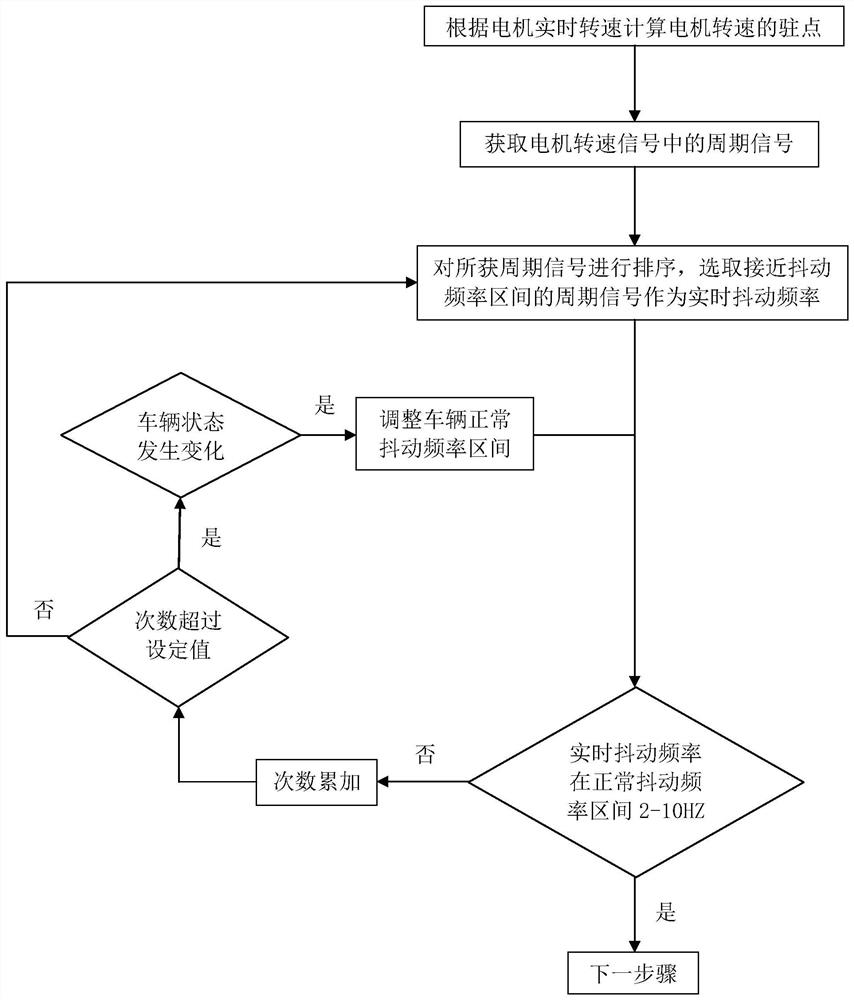

[0045] Embodiment: a kind of PR shake suppression method based on stagnation point calibration of this embodiment, such as Figure 1 ~ Figure 2 shown, including the following steps:

[0046] S1. Obtain the real-time speed of the motor based on the phase-locked loop, including:

[0047] S11. Based on the resolver, the rotor position signal of the motor is collected in real time, and the difference between the obtained rotor position signal and the estimated position signal is input into the phase-locked loop module, and the speed signal of the motor is obtained through closed-loop adjustment;

[0048] S12. Multiply the rotational speed signal of the motor by the fixed gain to perform unit conversion, and perform second-order filter processing on the obtained value, and finally obtain the target value as the real-time rotational speed of the motor;

[0049] S2. Determine the vibration frequency interval during the operation of the vehicle without any vibration suppression, specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com