A prefabricated component forming mold

A technology for forming molds and prefabricated components, which is applied in the direction of manufacturing tools, forming indenters, ceramic molding machines, etc., and can solve problems such as loose mold bonding, low vibration effect, and difficult cleaning of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

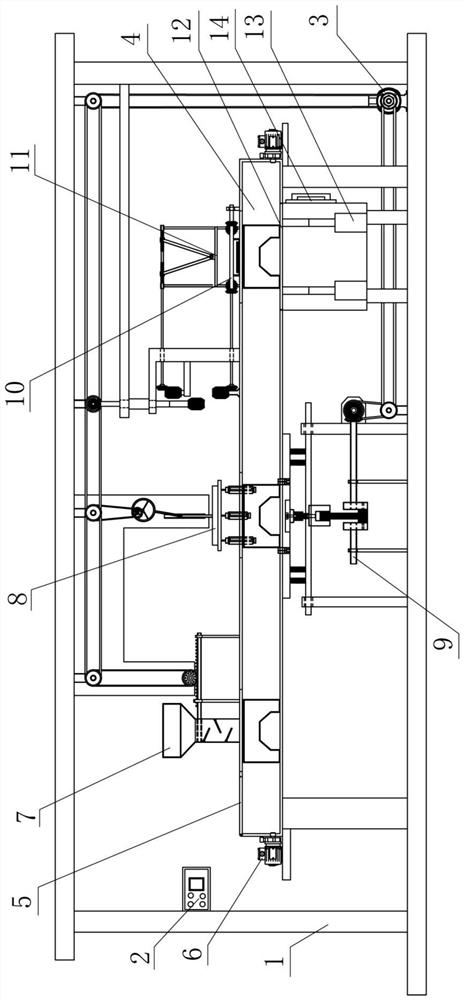

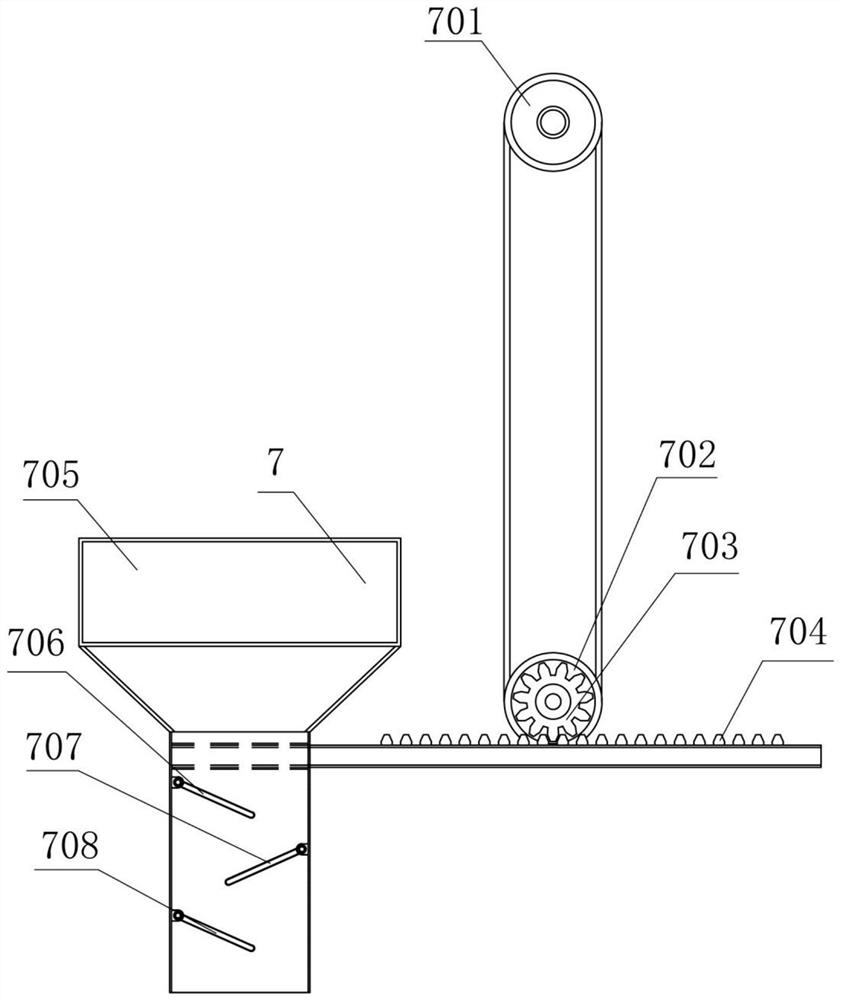

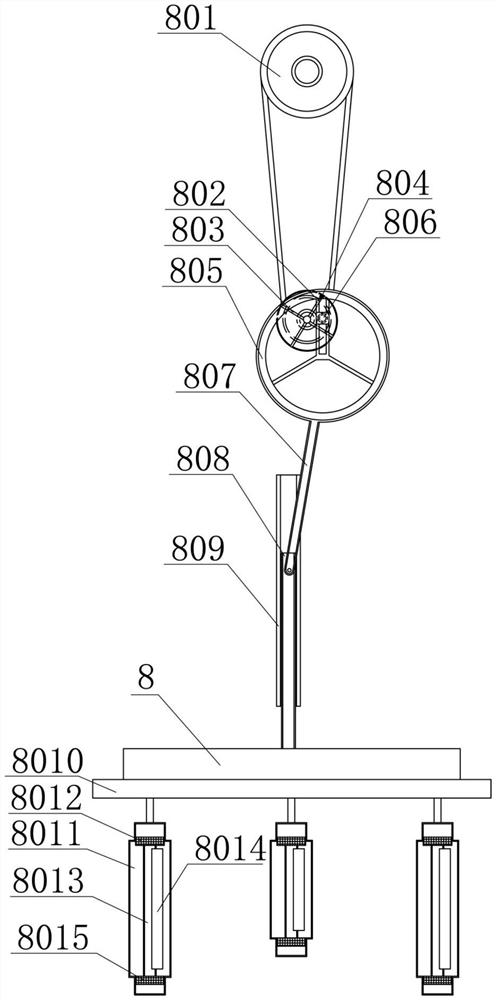

[0030] A prefabricated component forming mold, such as Figure 1-6 As shown, including the support frame 1, the control screen 2, the motor 3, the transport tube 4, the cover plate 5, the air pump 6, the feed mechanism 7, a variable ray vibration mechanism 8, the vibrating table 9, the stall mechanism 10, compaction The mechanism 11, the lifting plate 12, the first electric push rod 13 and the discharge port 14; the upper left end in the support frame 1 is provided above the upper left end, the motor 3 is provided on the right side of the bottom end of the support frame 1; the center of the support frame 1 The transport tube 4 is provided; an additive mechanism 7 is provided above the left side in the support frame 1, and the bottom of the feed mechanism 7 is connected to the transport tube 4; a variable ray vibration mechanism 8 is provided in the top of the support frame 1, and a variable speed The upper left end of the vibrating mechanism 8 is connected to the feed mechanism 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com