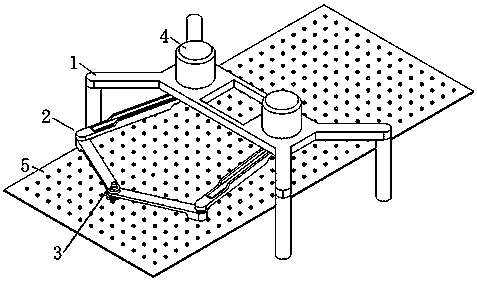

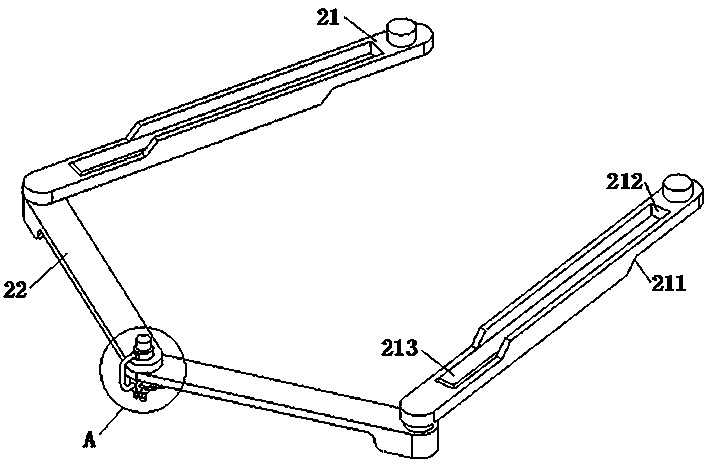

SCARA type high-speed parallel manipulator

A manipulator and parallel technology, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of slow movement of SCARA high-speed parallel manipulators and weaken the overall assembly efficiency of SCARA manipulators, so as to improve assembly efficiency, ensure accuracy requirements, and avoid interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

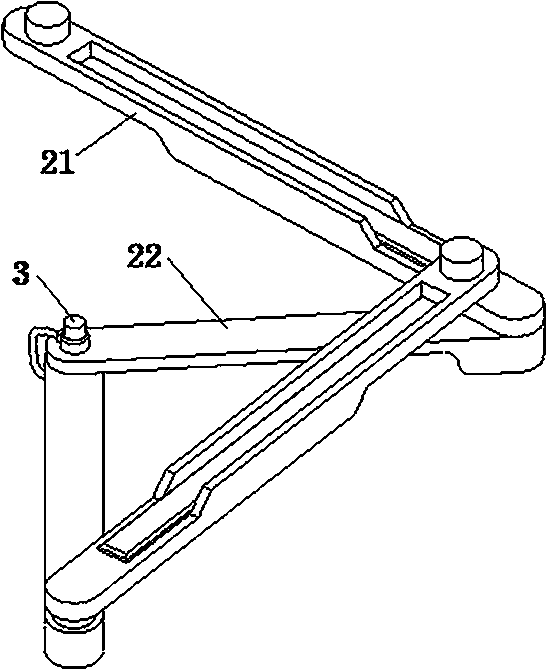

[0026] As an embodiment of the present invention, the suction head 32 is provided with an air supply hole 321, the air supply hole 321 is located in the center of the suction head 32, and the air supply hole 321 communicates the inside of the push rod 34 with the center of the suction head 32; A diaphragm 322 is arranged on the port of the air supply hole 321, and one end of the diaphragm 322 is attached to the bottom of the suction head 32; when working, the suction head 32 absorbs the parts assembled with the belt, and the servo motor 4 drives the moving joint 3 to the specified position. position, and then supply air to the push rod 34 through the air pipe 331. When the gas passes through the air supply hole 321, the diaphragm 322 is pushed away, so that the inside of the suction head 23 communicates with the outside, and the adsorbed components are separated by the effect of atmospheric pressure. The pressure difference of the suction head 32 is not obvious enough, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com