Preparation method of visible light response SnIn4S8 nanoparticle/TiO2 nanobelt core-shell type composite photocatalyst

A nanoparticle and nanobelt technology, applied in physical/chemical process catalysts, chemical instruments and methods, light water/sewage treatment, etc., to achieve high-efficiency transfer, increase light quantum yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (1) Weigh 4.0798g TiO 2 The nanobelts were added to 80mL ethylene glycol and water with a volume ratio of 1:1 ethylene glycol aqueous solution, stirred for 30 minutes, and ultrasonically treated for 30 minutes to form a uniform milky white TiO 2 Suspension.

[0030] (2) 4mmol: 16mmol: 40mmol is weighed successively by weighing tin tetrachloride pentahydrate, indium chloride and thioacetamide to the uniform TiO obtained in step (1) according to the ratio of substances. 2 In the suspension, stir for 30 minutes, after ultrasonic treatment for 30 minutes, transfer the suspension to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 120°C for 20 hours. After the reaction is completed, wait for it to cool to room temperature, recover, wash, and dry , the visible-light-responsive SnIn 4 S 8 Nanoparticles / TiO 2 Nanoribbon core-shell composite photocatalyst, in which TiO 2 The mass percentage of nanobelts in the composite structure is 55%.

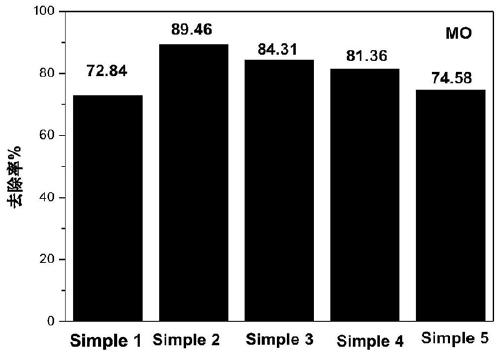

[0031] atta...

example 2

[0035] (1) Weigh 0.2504g TiO 2 The nanobelts were added to 30mL of ethylene glycol and water with a volume ratio of 1:0.5 in an aqueous ethylene glycol solution, stirred for 20 minutes, and ultrasonically treated for 15 minutes to form a uniform milky white TiO 2 Suspension.

[0036] (2) According to the molar ratio of substances, it is 0.2mmol: 0.8mmol: 3mmol, which takes successively weighed tin tetrachloride pentahydrate, indium chloride and thioacetamide and adds them to the uniform TiO obtained in step (1). 2 In the suspension, stir for 30 minutes, after ultrasonic treatment for 20 minutes, transfer the suspension to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 140°C for 20 hours. After the reaction is completed, wait for it to cool to room temperature, recover, wash, and dry , the visible-light-responsive SnIn 4 S 8 Nanoparticles / TiO 2 Nanoribbon core-shell composite photocatalyst, in which TiO 2 The mass percentage of nanobelts in the comp...

example 3

[0045] (1) Weigh 0.9736g TiO 2 The nanobelts were added to 50mL of ethylene glycol and water with a volume ratio of 1:0.6 in an aqueous ethylene glycol solution, stirred for 25 minutes, and ultrasonically treated for 25 minutes to form a uniform milky white TiO 2 Suspension.

[0046] (2) According to the molar ratio of substances, it is 0.5mmol: 2mmol: 5mmol successively weighs tin tetrachloride pentahydrate, indium chloride and thioacetamide and joins the uniform TiO obtained in step (1). 2 In the suspension, stir for 20 minutes, after ultrasonic treatment for 20 minutes, transfer the suspension to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 4 hours. After the reaction is completed, wait for it to cool to room temperature, recover, wash, and dry , the visible light responsive SnIn 4 S 8 Nanoparticles / TiO 2 Nanoribbon core-shell composite photocatalyst, in which TiO 2 The mass percentage of nanobelts in the composite structure is 70%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com