Preparation method and application of biomass honeycomb semicoke loaded nickel-iron nanoparticle catalyst

A granular catalyst and nanoparticle technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of a large amount of smoke, tar generation, waste of energy, etc. , to reduce pollution, increase specific surface area and pore volume, and reduce preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

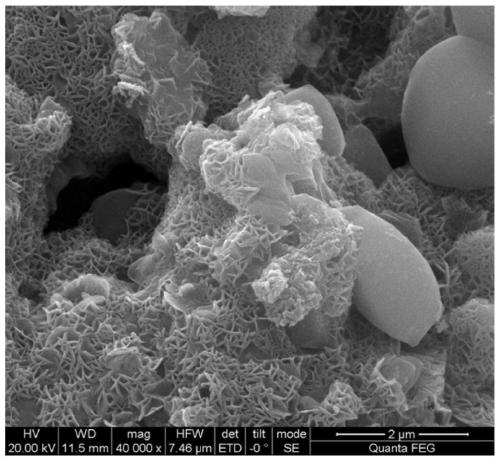

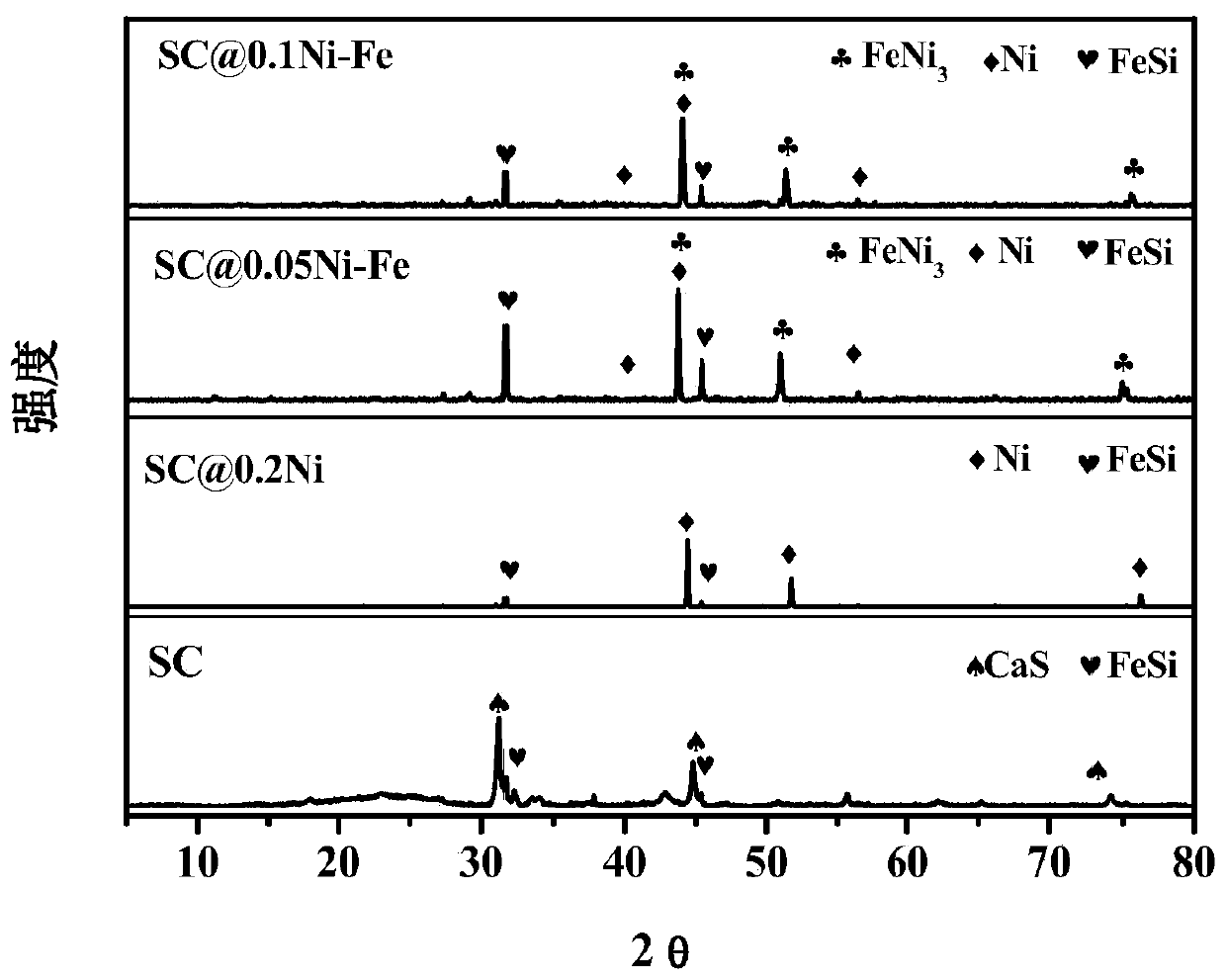

[0030] The raw material of Sargassum algae was washed with deionized water, dried at 105°C for 48 hours, crushed with a pulverizer, sieved to 40-80 mesh, and then dried for later use;

[0031] Weigh 13.5 g FeCl 3 ·6H 2 O and 11.85 gNiCl 2 ·6H 2 O solid was dissolved in 200 mL deionized water, weighed 20 g dry Sargassum powder and added FeCl 3 and NiCl 2 Mix the solution and stir it magnetically for 8 h at room temperature to make the Sargassum and FeCl 3 and NiCl 2 The mixed solution was fully contacted, and after the stirring was completed, it was dried in a drying oven at 105 °C for 24 h, and ground to obtain the SC@0.05Ni-Fe precursor;

[0032] Weigh 20 gSC@0.05Ni-Fe precursor and place it in a single temperature zone horizontal tube furnace, 2The gas flow rate was 500 mL / min, and the mixture was heated to 800 °C at a heating rate of 10 °C / min and kept for 60 min. After natural cooling was completed, a biomass honeycomb semi-coke supported nickel / iron nanoparticle ca...

Embodiment 2

[0035] Sargassum raw material was washed with deionized water, dried at 105 °C for 48 h, crushed with a pulverizer, sieved to 40-80 mesh, and then dried for later use;

[0036] Weigh 27 g FeCl 3 ·6H 2 O and 23.7 gNiCl 2 ·6H 2 O solid was dissolved in 200 mL deionized water, weighed 20 g dry Sargassum powder and added FeCl 3 and NiCl 2 Mix the solution and stir it magnetically for 8 h at room temperature to make the Sargassum and FeCl 3 and NiCl 2 The mixed solution was fully contacted, and after the stirring was completed, it was dried in a drying oven at 105 °C for 24 h, and ground to obtain the SC@0.1Ni-Fe precursor;

[0037] Weigh 20 gSC@0.1Ni-Fe precursor and place it in a single temperature zone horizontal tube furnace, 2 The gas flow rate is 300-700 mL / min, and the mixture is heated to 800-900 °C at a heating rate of 10-15 °C / min and maintained for 60-90 min. After natural cooling is completed, biomass honeycomb semi-coke loaded nickel / iron is prepared Nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com