Laying hen feed capable of increasing yolk chroma and realizing accurate proportioning

A technology for laying hen feed and feed raw materials, which is applied in the field of biological fermentation feed production, can solve the problems of unstable pigments, inability to control the type, content and dosage of Monascus pigments stably, and attenuation of pigment content, and achieves stable chemical structure, The effect of improving egg production performance and stable pigment content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

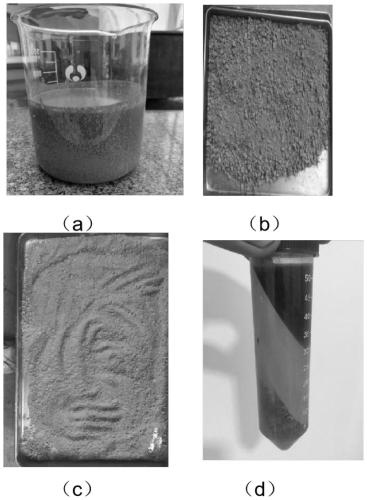

[0073] Embodiment 1: the preparation of red yeast orange pigment material

[0074] Monascus orange pigment is prepared as follows:

[0075] The production process of Monascus orange raw material is as follows: Figure 7 Shown:

[0076] The preparation method of the monascus orange pigment is as follows: inoculate the Monascus seed liquid producing the monascus orange pigment into (g / L) cornstarch 60, ammonium sulfate 5.0, KH 2 PO 4 2.0,K 2 HPO 4 2.0, MgSO 4 ·7H 2 O 0.5, CaCl 2 0.1, FeSO 4 ·7H 2 O 0.01, ZnSO 4 ·7H 2 O 0.01, MnSO 4 ·H 2 O 0.03, NaNO 3 2.0, lactic acid to adjust the pH to 4.0, the inoculum amount, 10%; after 120 hours of fermentation, the fermentation is ended, and the color value of the fermentation liquid: 450-600U / mL. Add 10-20% (according to the volume of fermentation broth) soybean oil to the fermented liquid, stir at 30°C for 30 minutes, centrifuge, collect the oil phase by centrifugation, add cornstarch 1-2 times the mass of the oil phas...

Embodiment 2

[0079] Embodiment 2: the preparation of red yeast yellow pigment material

[0080] Monascus yellow pigment is prepared by the following method:

[0081] The production process of Monascus yellow pigment is as follows: Figure 8 Shown:

[0082] The preparation method of Monascus yellow pigment is: inoculate the Monascus seed liquid producing Monascus yellow pigment into (g / L) cornstarch 60, ammonium sulfate 5.0, KH 2 PO 4 2.0,K 2 HPO 4 2.0, MgSO 4 ·7H 2 O 0.5, CaCl 2 0.1, FeSO 4 ·7H 2 O 0.01, ZnSO 4 ·7H 2 O 0.01, MnSO 4 ·H 2 O 0.03, NaNO 3 2.0, lactic acid to adjust the pH to 4.0, the inoculum amount, 10%; after 120 hours of fermentation, the fermentation is ended, and the color value of the fermentation liquid: 450-600U / mL. Add 10-20% (according to the volume of fermentation broth) soybean oil to the fermentation broth, stir at 30°C for 30 minutes, centrifuge, collect the oil phase by centrifugation, add cornstarch 1-2 times the volume of the oil phase, and ...

Embodiment 3

[0086] Embodiment 3: the preparation of monascus red pigment material

[0087] The monascus red pigment is converted from the residual pigment in the fermentation broth after the oil phase is separated from the monascus yellow pigment or the monascus orange pigment fermentation broth of Example 1 or Example 2. The amount of pigment in the fermented liquid after separating the oil phase is about one-third of the amount of the pigment in the fermented liquid.

[0088] The production process of Monascus red pigment is as follows: Figure 9 Shown:

[0089] Add 3-5% (mass volume ratio) feed material (corn flour or soybean meal powder containing protein) in the fermented liquid after embodiment 1 or embodiment 2 centrifugation oil phase, and be warming up to certain temperature (50-60 degree) for a certain period of time (30-60min), and some residual pigments in the fermentation broth react with the proteins, peptides and amino acids in the feed materials to produce monascus red p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com