Fatigue test fixing device for composite material pipe

A composite material tube and fatigue test technology, applied in the field of fatigue test fixtures, can solve the problems of not being able to meet the requirements of the composite material tube fatigue test, the difficulty of applying the fatigue test of the tubular sample, and the slippage of the sample required by the fatigue test. The effect is good, the initial damage is small, and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

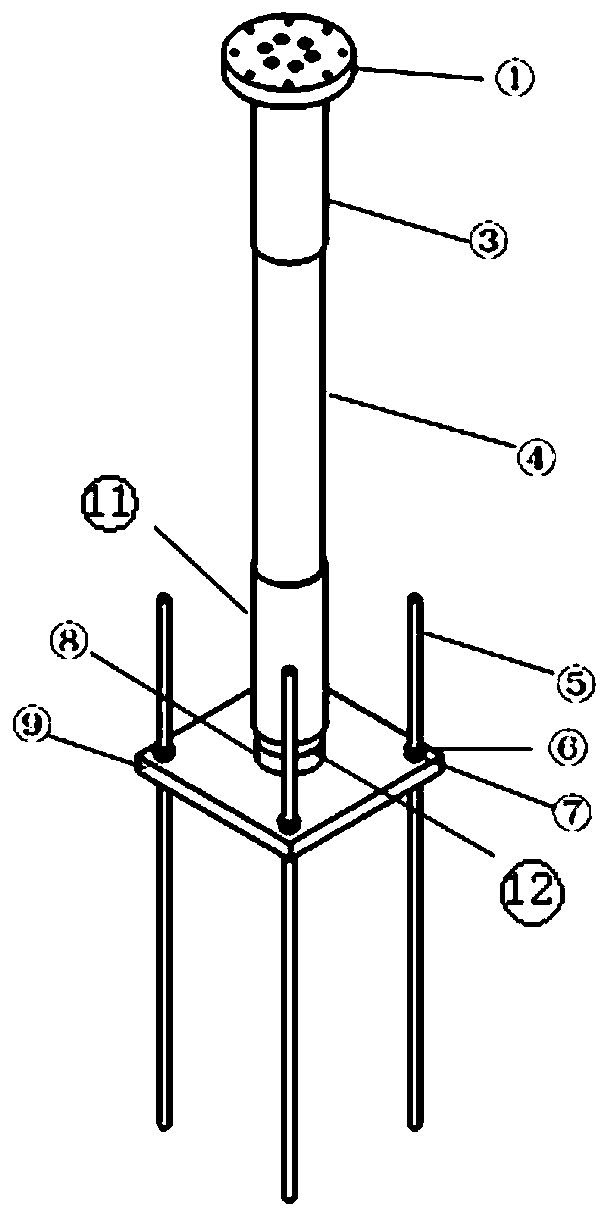

[0050] When installing the device of the present invention, comprise the following steps:

[0051] (1) Four threaded pull rods 5 are fixed on the fatigue testing machine;

[0052] (2) adjust the height of the base 9 according to the length of the composite pipe sample 4 used in the experiment, and fix it;

[0053] (3) Assemble the sample tube, inner core and overcoat together, and crimp the outer protective sheath with a crimping machine;

[0054] (4) Connect the upper adapter flange with the inner core with 6 bolts with an outer diameter of 0.8 units;

[0055] (5) Connect the lower adapter flange with the inner core with 6 bolts with an outer diameter of 0.8 units;

[0056] (6) Connect the upper adapter flange with the loading device of the fatigue testing machine with 8 bolts of 0.6 units;

[0057] (7) Use a bolt with a diameter of 1 unit to connect the upper adapter flange with the base of the fatigue testing machine. Installed.

[0058] After the installation is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com