Universal testing tool for three-axis gyroscope

A general-purpose testing and gyroscope technology, applied in measurement devices, Sagnac effect gyroscopes, instruments, etc., can solve problems such as waste of resources, waste of manpower, delay in production cycle, etc., and achieve convenient and rapid assembly, weight reduction, and difficulty reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

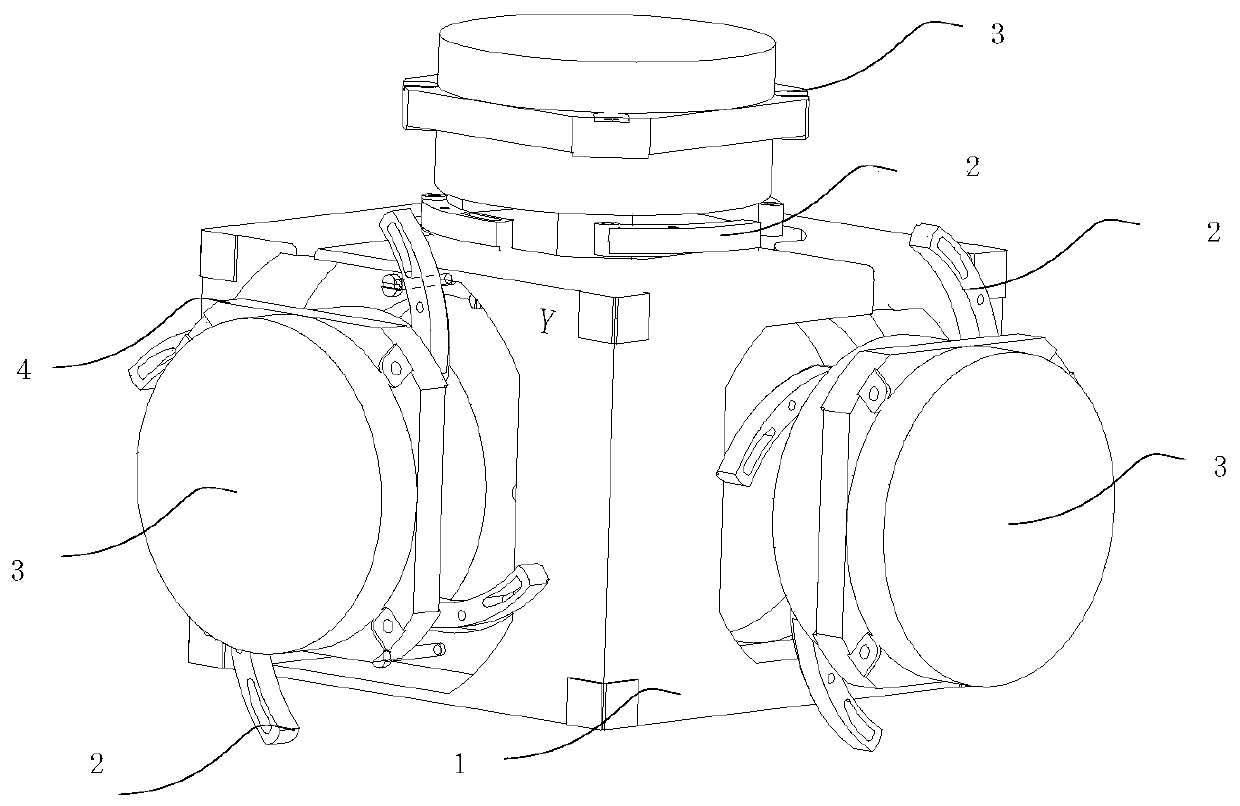

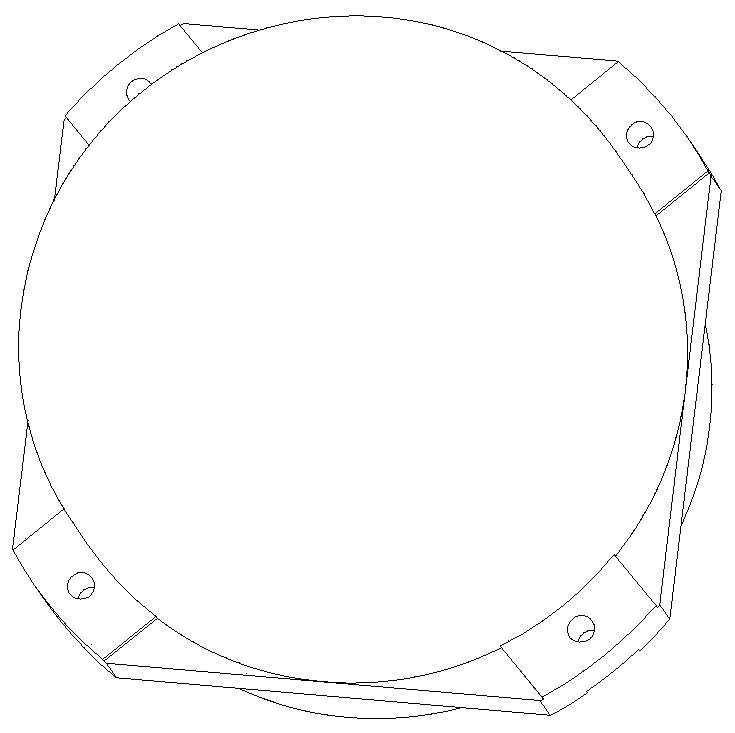

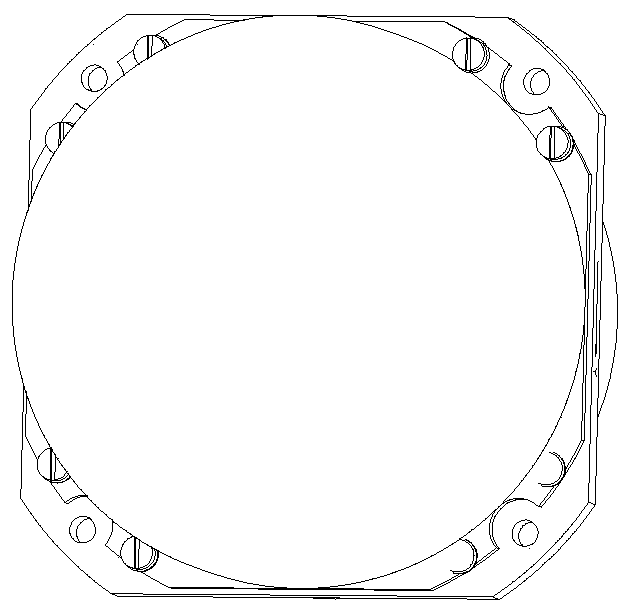

[0034] Such as Figure 1-9 , in this embodiment, a general test fixture for a three-axis gyroscope, including a fixture body 1 , an adapter bracket 2 , and a pressure block 4 .

[0035] Tooling body 1 is used as a carrier for carrying three-axis gyroscopes and realizing gyroscope test performance, and the reference provided by it must be very accurate. Therefore, in the hexahedral test tooling, each surface is designed with a reference plane, and the six sides of the test tooling are required to have High geometric tolerance. In order to achieve universality of tooling body 1 and fast positioning of each type of gyroscope after installation, error prevention measures are also very important. Therefore, the mounting holes of adapter bracket 2 and the mounting surface of adapter bracket 2 of tooling body 1 are designed Marks 5, 6, 7, and 8 correspond to different types of gyroscopes. When installing the gyroscope, it is only necessary to align the mounting hole marks of the ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com