Composite pipe layering seal connector structure and preparing method thereof

A technology for sealing joints and composite pipes, which is applied in the direction of pipes/pipe joints/pipe fittings, hose connection devices, mechanical equipment, etc. problems such as operation, limited joint crimping equipment working diameter, etc., to achieve the effect of low cost of use, strict sealing and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

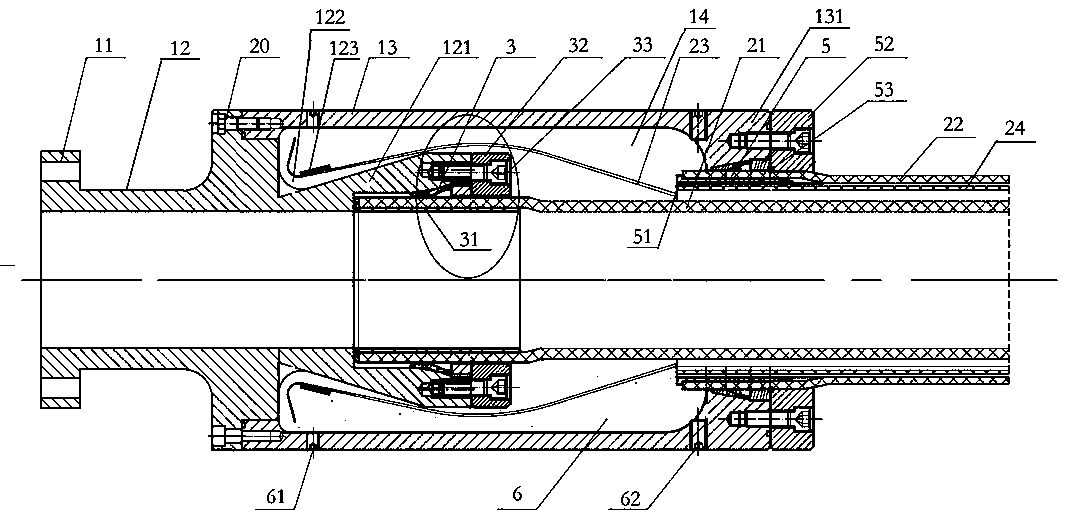

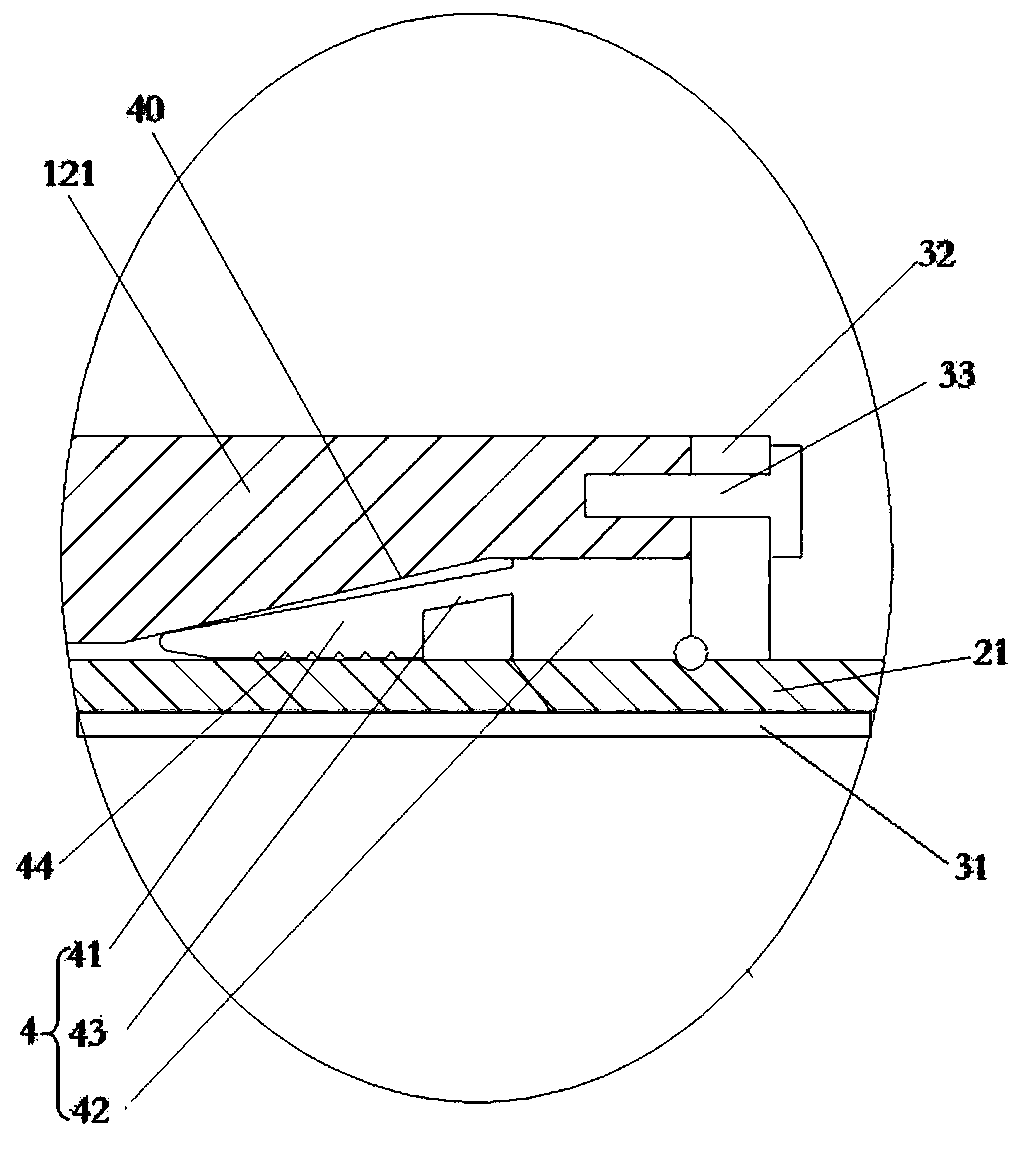

[0025] The structure and working principle of a composite pipe layered sealing joint provided by the present invention will be further described in detail below with reference to the accompanying drawings.

[0026] see figure 1 , figure 2 , is a schematic diagram of a layered sealing joint structure of a composite pipe provided by the present invention. The structure of the new layered sealing joint includes a layered peeling nozzle that is sealed and connected with the joint body. The joint body includes a flange 11 and a connecting pipe 12. The connecting pipe 12 and the inner core layer 21 of the composite pipe are realized through flange connection. The inner seal 3, the connecting pipe 12 is provided with a sleeve 13, one end of the sleeve 13 is flanged to the connecting pipe 12 20, the other end of the sleeve 13 and the outer sheath 22 of the composite pipe are flanged to realize the outer Sealing 5, there is a cavity 14 between the sleeve 13 and the connecting pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com