Fixing structure and installation method of aircraft craft floor

A technology for fixing structures and floors, applied in aircraft assembly, etc., can solve problems such as safety hazards in production, irregular laying, and unfixed floors, and achieve the effects of convenient installation and operation, high promotional value, economic benefits, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

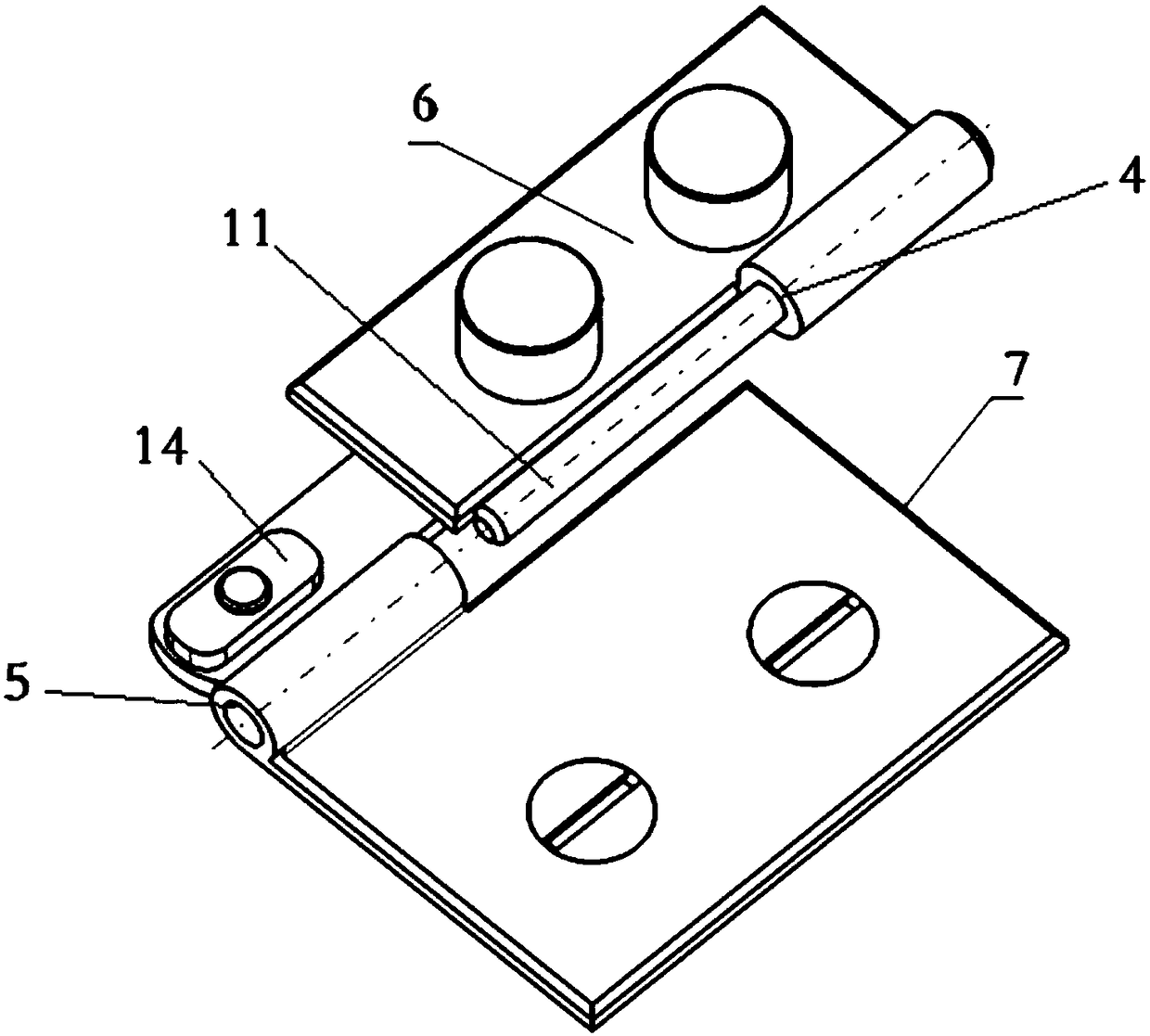

[0015] see figure 1 , The floor fixing structure 5 of this process is composed of two parts, the ground rail fixing component 6 and the floor fixing component 7, which form a hinge structure that can be opened and closed.

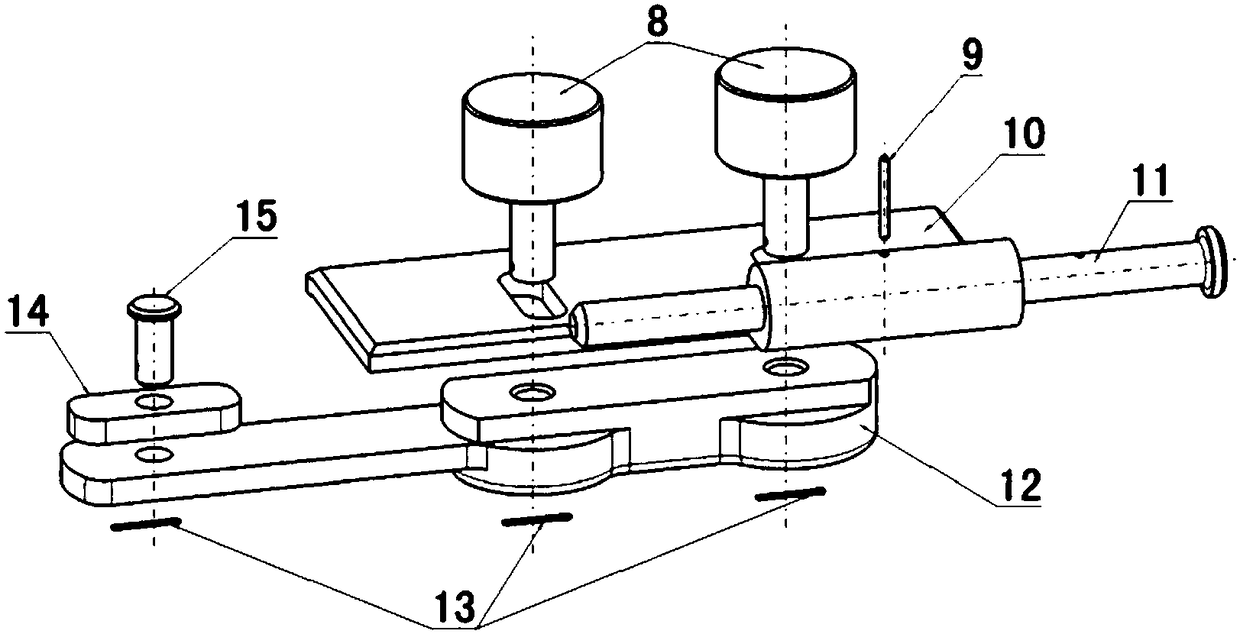

[0016] see figure 2 It can be seen that the ground rail fixing assembly 6 is assembled from the upper clamping plate 10 of the ground rail, the T-groove clamping part 12 of the ground rail, the positioning key 14 at the tail, the cylindrical pin 9, the hinge shaft 11, and the pin shaft 15. One side of the upper clamping plate 10 of the ground rail is provided with a first hinge hole 4, the hinge shaft 11 passes through the first hinge hole 4, and the cylindrical pin 9 is inserted between the hinge shaft 11 and The limit hole on the first hinge hole 4 is limited, the ground rail T-slot clamping part 12 can be embedded in the spline groove of the cabin ground rail 2, and the tail positioning key 14 can pass through the pin shaft 15 Fixed on the tail of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com