Connection structure of compressed air pipe

A technology for compressed air pipes and connection structures, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc. Simple, firm and safe connection, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

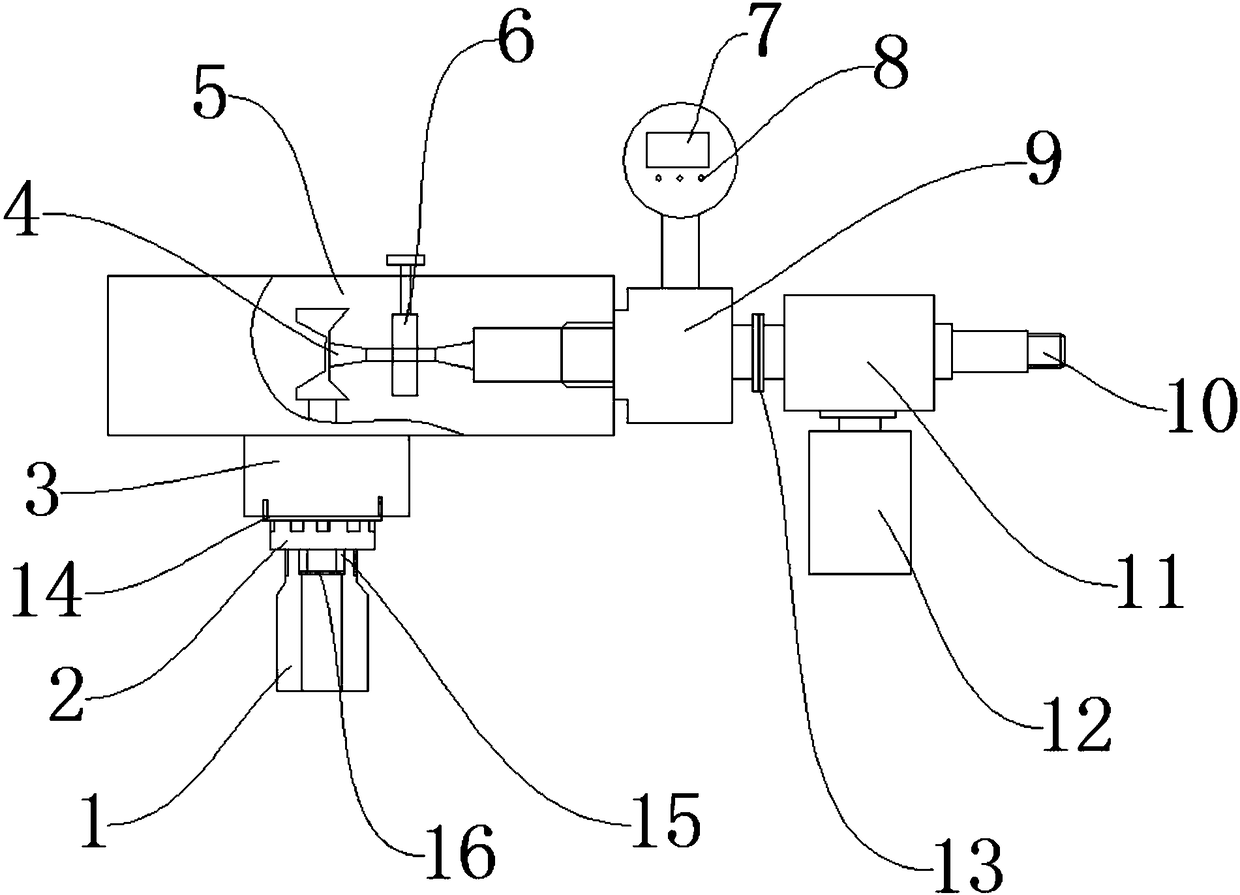

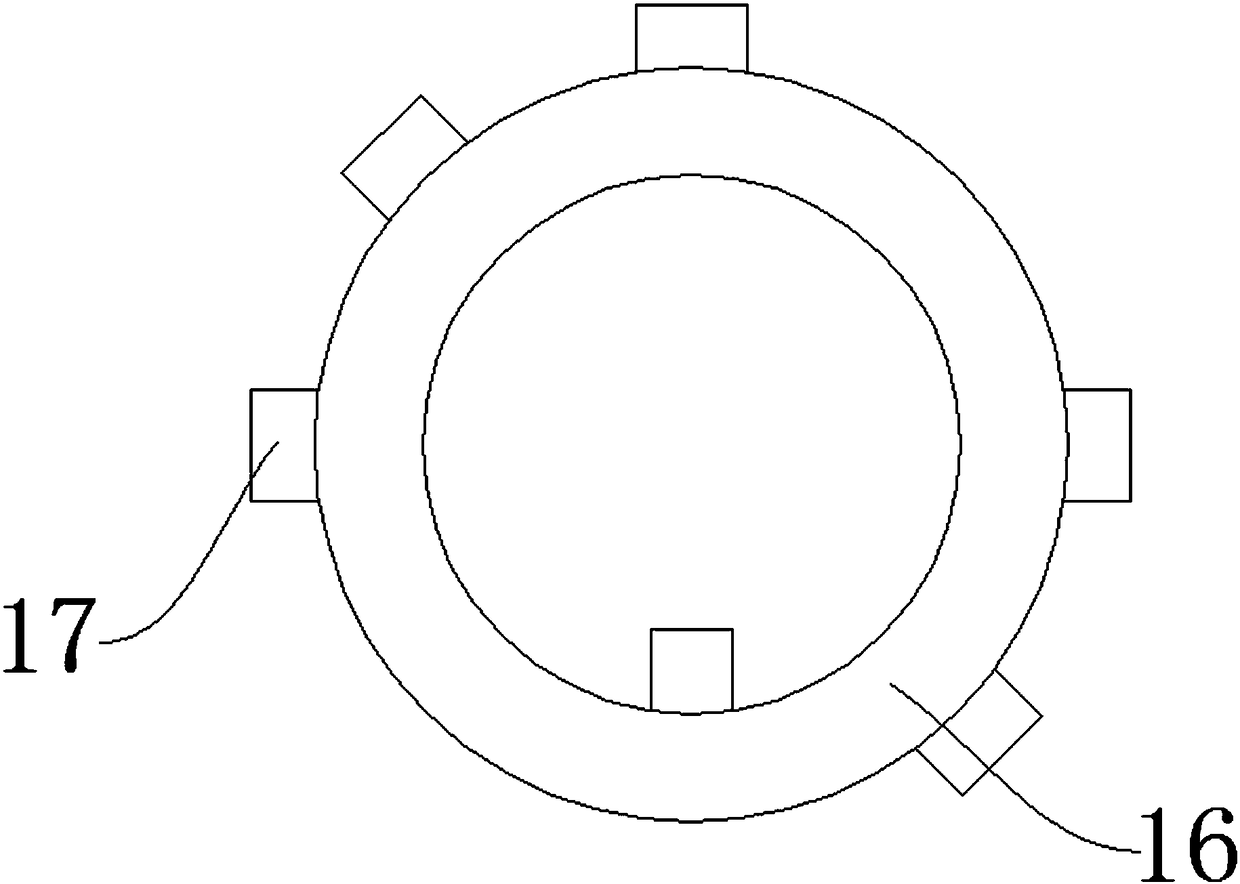

[0020] Such as Figure 1-Figure 2 As shown, a compressed air pipe connection structure includes the air intake pipe 1, the steering seat 5, the connecting seat 3 is arranged under the steering seat 5, and the air intake pipe is arranged under the connecting seat 3. Joint 15, the air intake pipe 1 is arranged under the air intake joint 15, the air intake pipe 1 is used to connect the air compressor, and the lock is arranged outside the connection between the air intake pipe 1 and the air intake joint 15 Locking nut 2, described locking nut 2 is used for conveniently fixing described air intake pipe 1, described locking piece 14 is arranged on described locking nut 2, and described locking piece 14 is used for preventing described locking nut 2 loose, the steering seat 5 is provided with the pressurized chamber 4, the pressurized chamber 4 is used to speed up the air flow, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com