Internal support trolley system of shield tunnel under the condition of small spacing, shallow covering soil and small radius

A technology of shield tunneling and internal support, which is applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of easy damage to mechanical round supports, no space for muck trucks to travel, and high cost of support devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

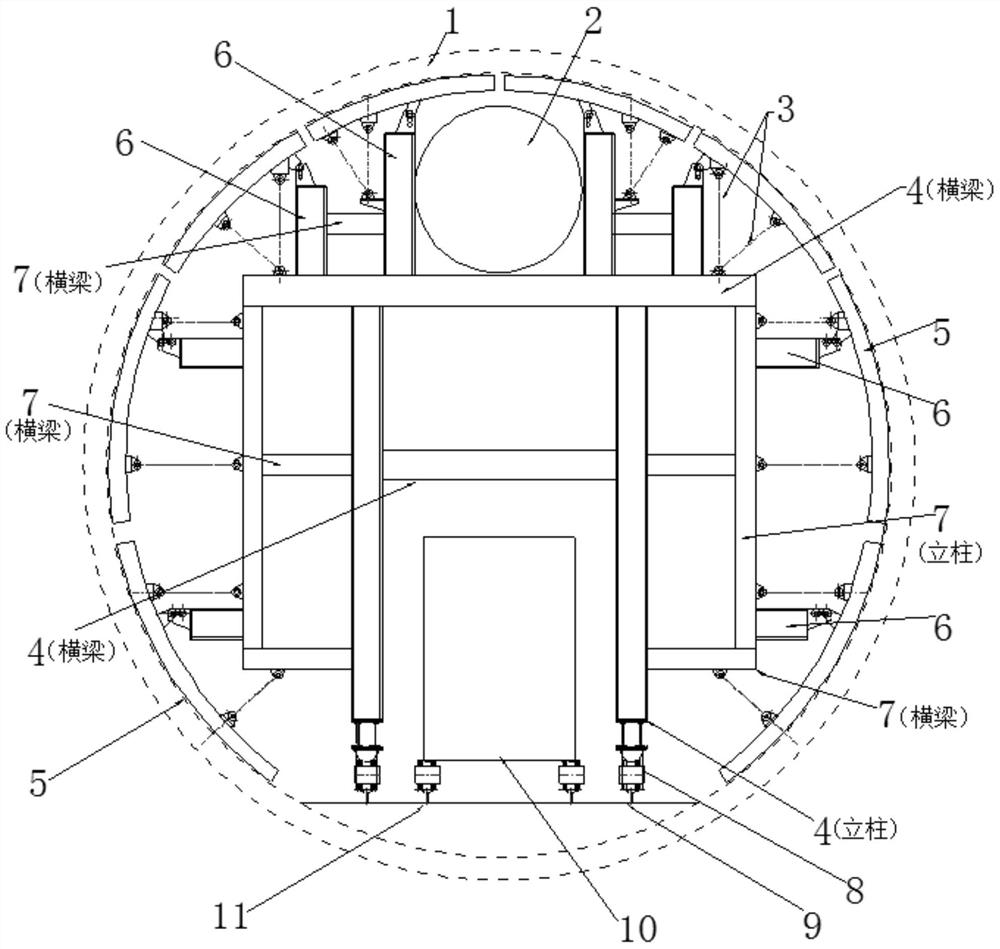

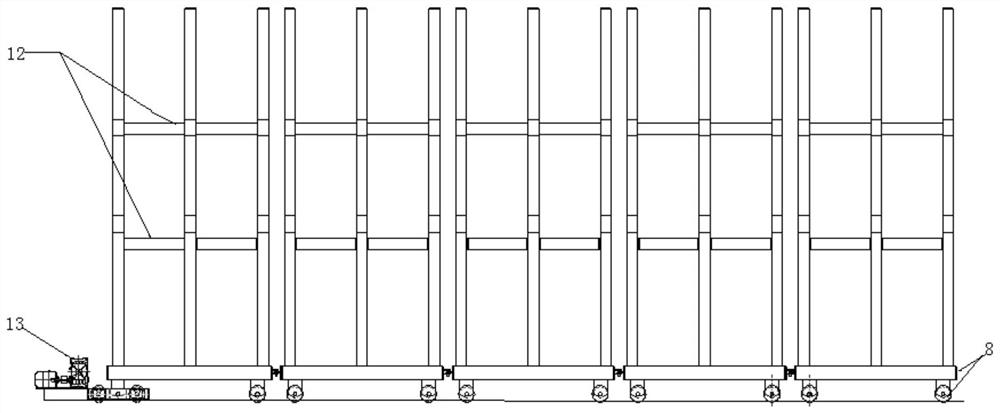

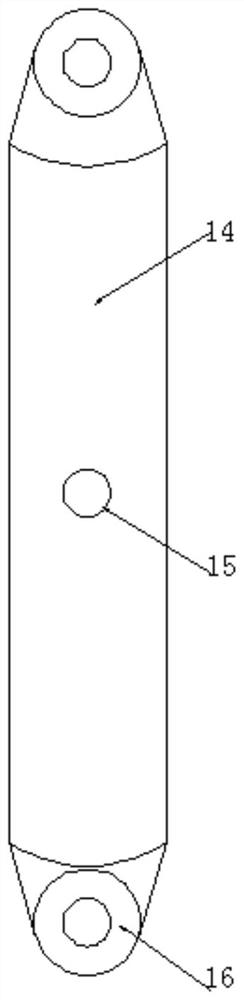

[0031] Such as figure 1 As shown, a shield tunnel internal support trolley system under the condition of small spacing, shallow overburden and small radius, including the trolley track 9 and the muck truck track 11 at the bottom of the tunnel, and the trolley and dregs respectively matched with the two Car 10; the trolley track 9 adopts the original shield trolley walking track; the trolley includes a frame, a running mechanism 8 and a supporting mechanism, the upper part of the frame can accommodate the ventilation duct 2, and the lower part spans the muck truck 10 Without interfering with it, the support mechanism includes arc-shaped planks 5, sliding hinges 6 and telescopic top pieces 3. The arc-shaped planks 5 are distributed on the upper part and both sides of the tunnel with gaps between adjacent ones. The arc-shaped planks 5 Through the slidable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com