Subway tunnel vibration and noise control method

A noise control and tunneling technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as local strength reduction, difficulty in achieving ideal results, and damage to the integrity of the shield shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

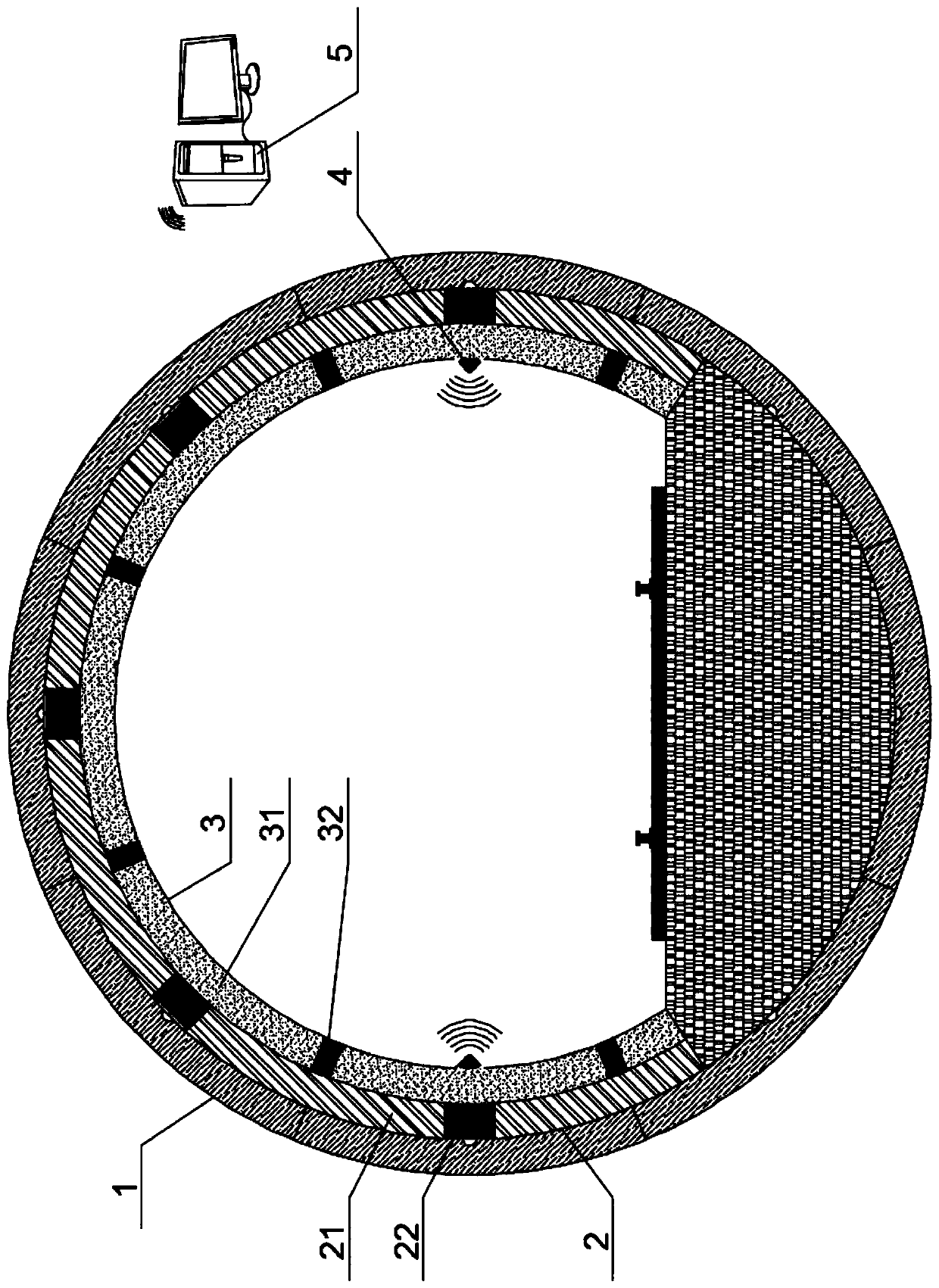

[0030] Such as figure 1 As shown, the subway tunnel monitoring and protection system includes an anti-shock and vibration-reduction layer I2, an anti-shock and vibration-reduction layer II3, a signal collecting and transmitting device 4 and a centralized electric control device 5.

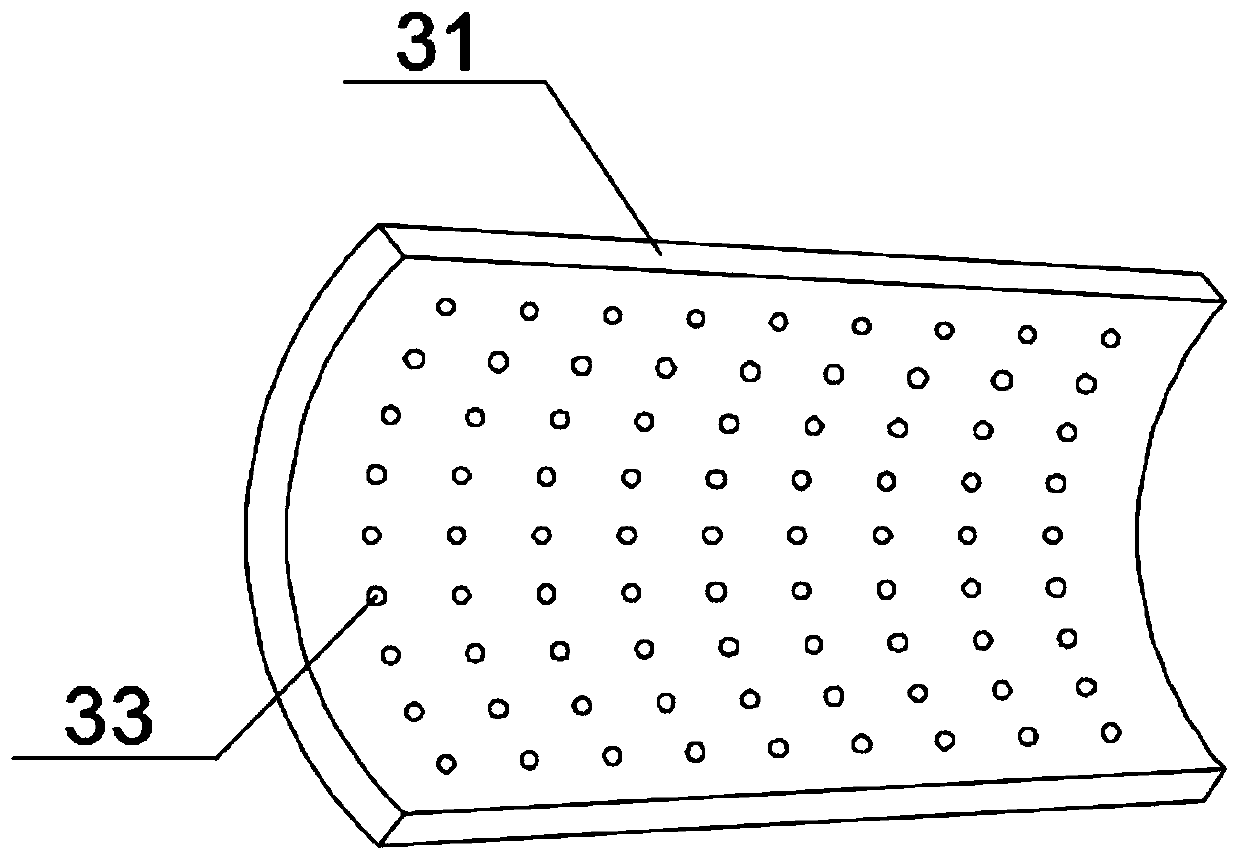

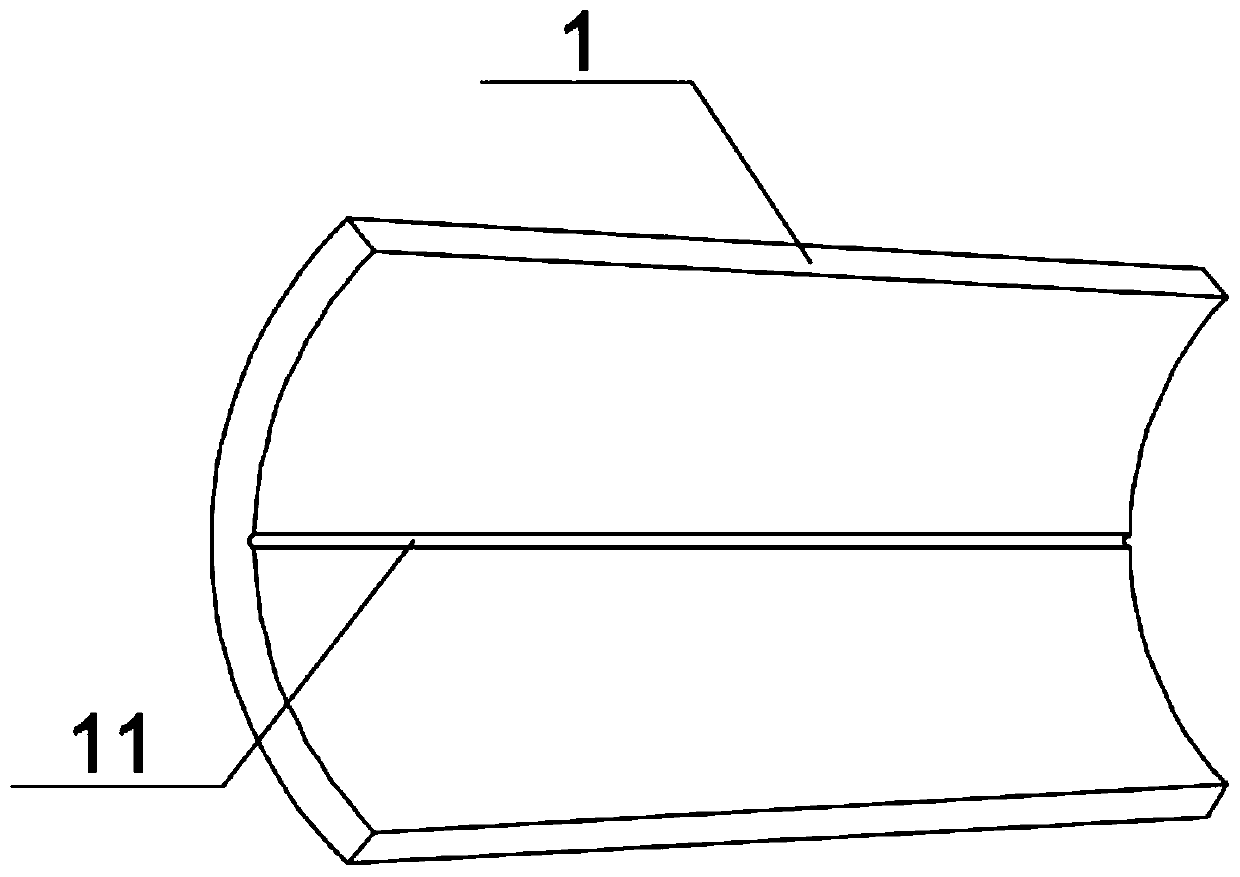

[0031] The anti-shock and vibration-absorbing layer I2 is fixedly arranged on the inner surface of the shield casing 1, including a high-damping vibration-damping ring 21 and an adjustable damping vibration-absorber I22, and the outer diameter of the high-damping vibration-damping ring 21 is the same as the shield The inner diameter of the shield shell 1 is matched, and the high-damping vibration-damping ring 21 is fixedly installed and connected to the shield shell 1. The high-damping vibration-damping ring 21 can be made of materials such as rubber concrete, polymer-based damping composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com