Fixing formwork and reinforcing method for underground pipe gallery with steel edge rubber water stop belt

A technology of rubber waterstop and underground pipe gallery is applied in the fixed formwork and reinforcement of the steel edge rubber waterstop of the underground pipe gallery, and the installation and construction of the flexible waterstop of the deformation joint of the pipe gallery, which can solve the problem of the rubber waterstop. It is easy to cause problems such as displacement and water stop damage, so as to achieve the effect of easy operation and maintenance, easy maintenance, and avoidance of structural leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Since the traditional waterstop reinforcement method usually uses side formwork and surrounding scaffolding to position and reinforce it, it is often prone to displacement when pouring concrete and vibrating, resulting in installation deviations that cause structural leakage, and external leakage of the waterstop Part of it is also very vulnerable to damage, and its structural waterproof function is also affected, which brings a lot of inconvenience to the operation and maintenance of the pipe gallery in the later stage.

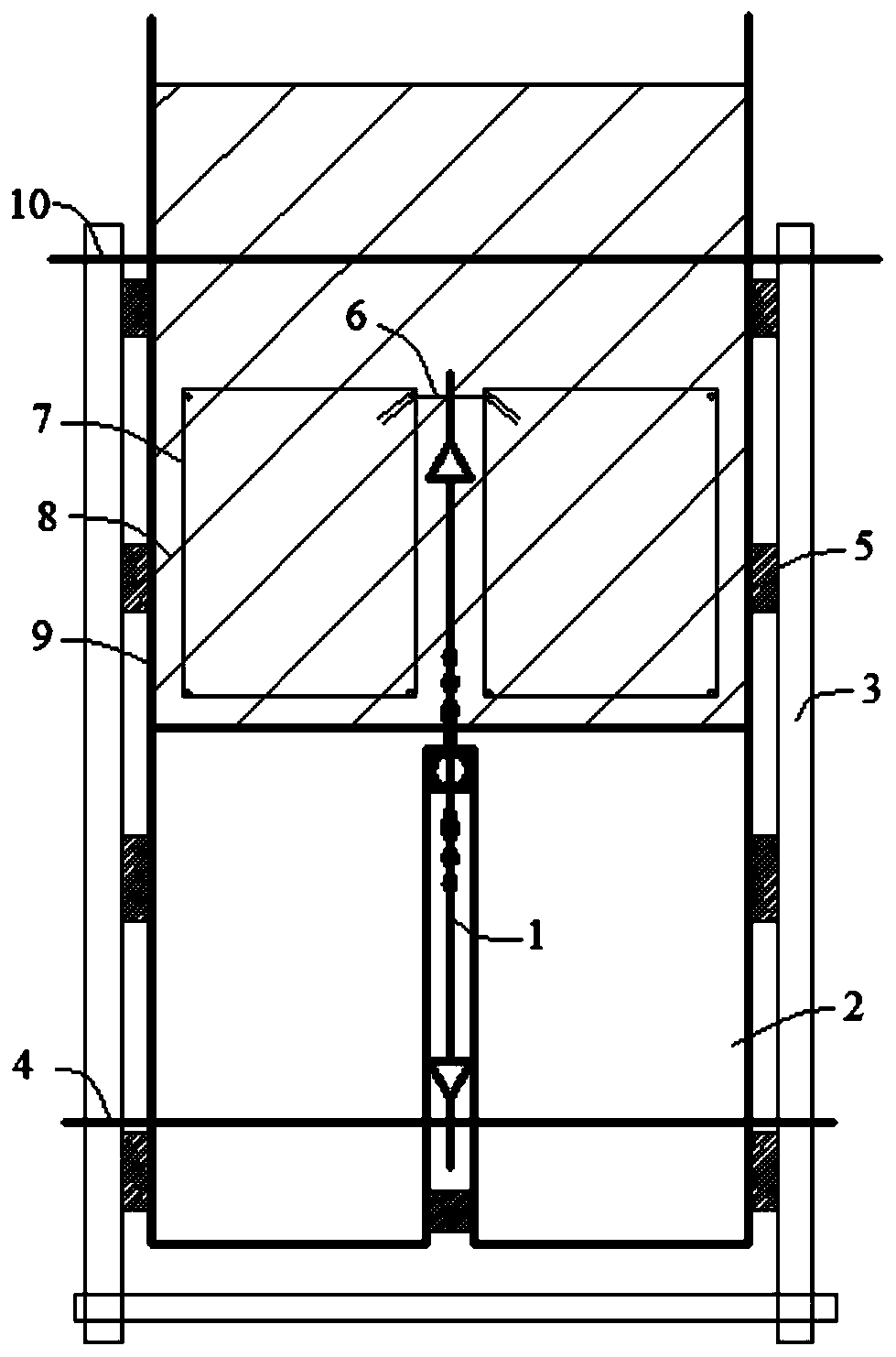

[0034] Based on the above situation, the present invention provides a fixed formwork for an underground pipe gallery with a steel-edged rubber waterstop, including positioning steel bars 7 and a fixed frame. Such as figure 1 As shown, holes are arranged on both ends of the steel edge of the rubber waterstop 1, and one end passes through the steel edge of the rubber waterstop 1 through the round steel 6 and is welded and fixed on the positioning steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com