Combined type lattice form prefabricated pile wall support protecting structure and construction method thereof

A support structure and combined technology, applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problem of short length of prefabricated prestressed concrete hollow square piles, low bending resistance and low shear resistance of single piles, which cannot be applied Deep foundation pit engineering and other problems, to achieve the effect of excellent soil retaining and water-stop performance, reliable pile quality, and reduce the elevation of prefabricated pile tops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

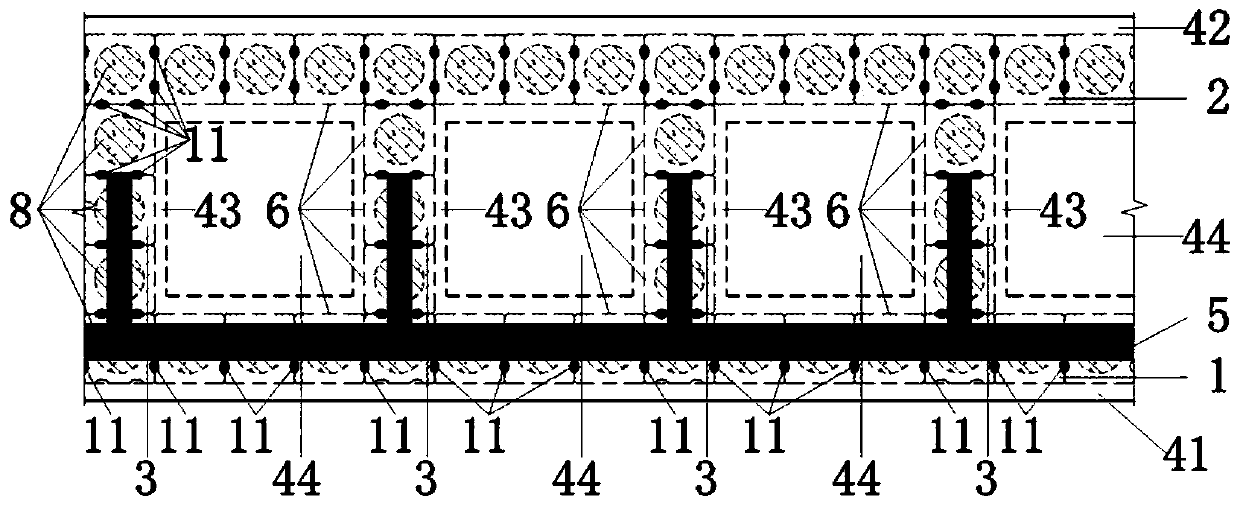

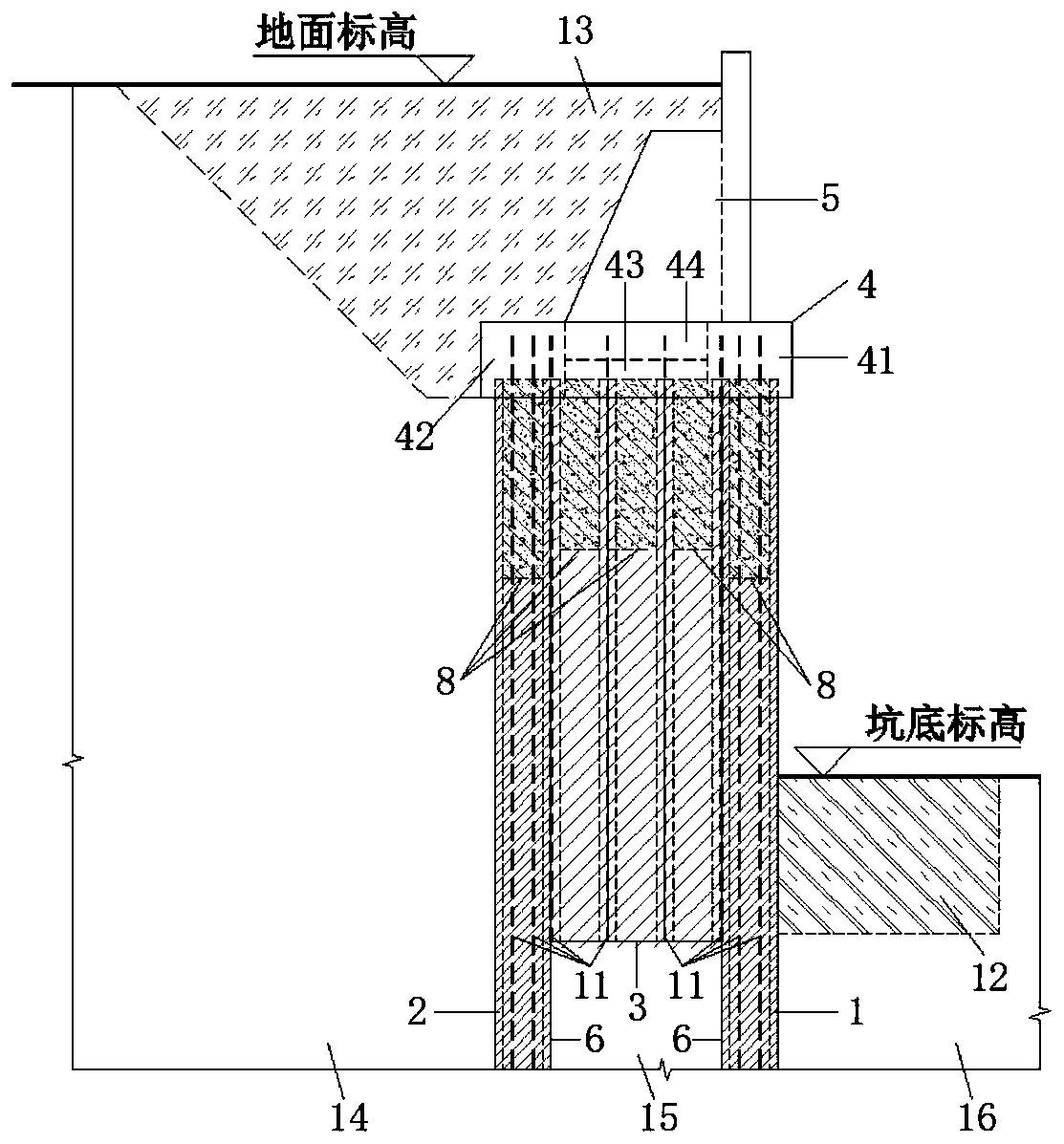

[0033] 1. Basic structure

[0034] The combined lattice prefabricated pile wall support structure includes a front row of pile walls, a rear row of pile walls, an intermediate pile wall, a platform slab and a buttress retaining wall.

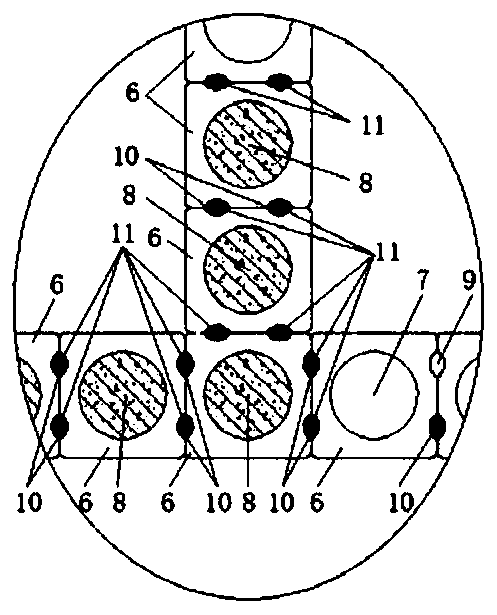

[0035] The front row of pile walls and the rear row of pile walls are two parallel rows of prefabricated prestressed concrete hollow square piles in close arrangement (dense arrangement), and the middle pile wall is densely packed with several rows vertically located between the front row of pile walls and the rear row of pile walls. For a row of prefabricated prestressed concrete hollow square piles, the distance between the front row of pile walls and the rear row of pile walls (net spacing) is 3.0-10.0 times the side length of the square piles, and the length of the middle pile wall is not greater than the length of the front row of pile walls. The row spacing (net spacing) is 3.0-8.0 times the side length of the square pile; the cavity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com