Super high-rise building structure without inner tube

A building structure and super high-rise technology, applied in the direction of building structure, construction, etc., can solve the problems of poor economy, increase the anti-overturning moment, increase the construction cost, etc., and achieve the effect of low concrete consumption and strong shear bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

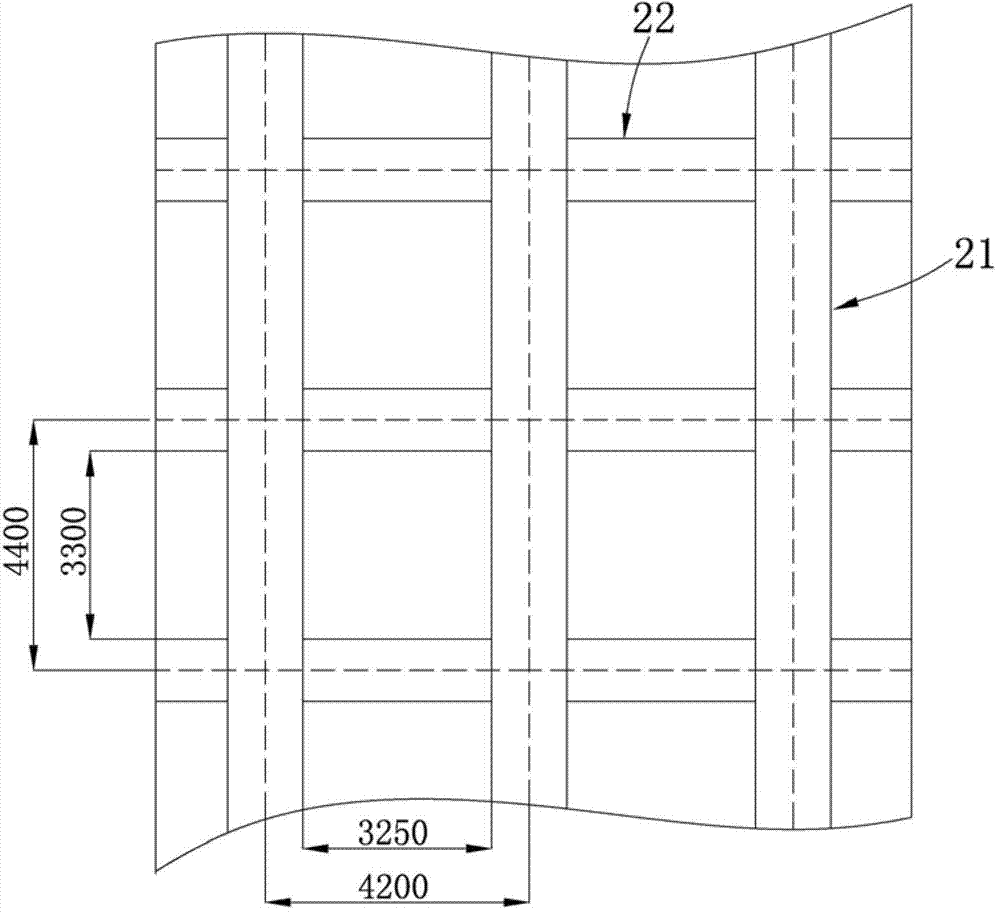

[0044] like Figures 1 to 3 As shown, the super high-rise building structure without an inner tube in this embodiment includes: an outer frame tube structure formed by combining the first SRC columns and SRC window skirt beams 22, and an inner frame structure formed by combining vertical columns 11 and connecting beams 12 , and several floors for connecting the outer frame tube structure and the inner frame structure. The inner frame structure is set eccentrically, and its geometric center deviates from the geometric center of the outer frame tube, as shown in the attached image 3 The geometric center of the inner frame structure shown is located in the northwest area of the outer frame tube structure. If the traditional frame-core tube structure is adopted, the design of the inner core tube and the design of the connecting beam between the outer frame and the inner core tube will be quite complicated and difficult to design. However, after using the structure of the oute...

Embodiment 2

[0063] like Figure 7 As shown, the super high-rise building structure without an inner tube in this embodiment includes: an outer frame tube structure formed by combining the first SRC columns 61 and SRC window skirt beams 62; an inner tube structure formed by combining the vertical columns 51 and connecting beams 52; frame structure, and several floors for connecting the outer frame tube structure and the inner frame structure.

[0064] like Figure 7 As shown, the cross-section of the outer frame tube of this embodiment is rectangular, and no columns are set at its four corners. Each side of the outer frame tube structure has nine first SRC columns 61 with a column distance of 4.5m. The horizontal section of the inner frame structure is rectangular, the vertical columns 51 at the four corners are reinforced SRC columns, and the rest are ordinary SRC columns. The vertical columns 51 of the inner frame structure are arranged symmetrically. For either side, there are two ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com